Small deep hole inner wall ultrasonic vibration machining cutter and a preparation method thereof

An ultrasonic vibration and tool processing technology, applied in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of easy wear, tool friction heat generation and poor cooling effect, etc., to increase the chip space, The effect of improving tool strength, improving machining stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

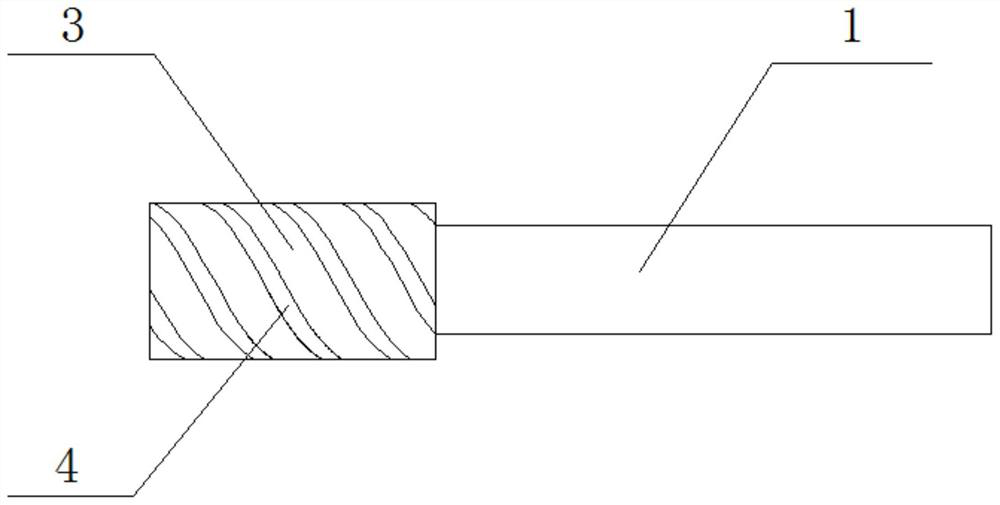

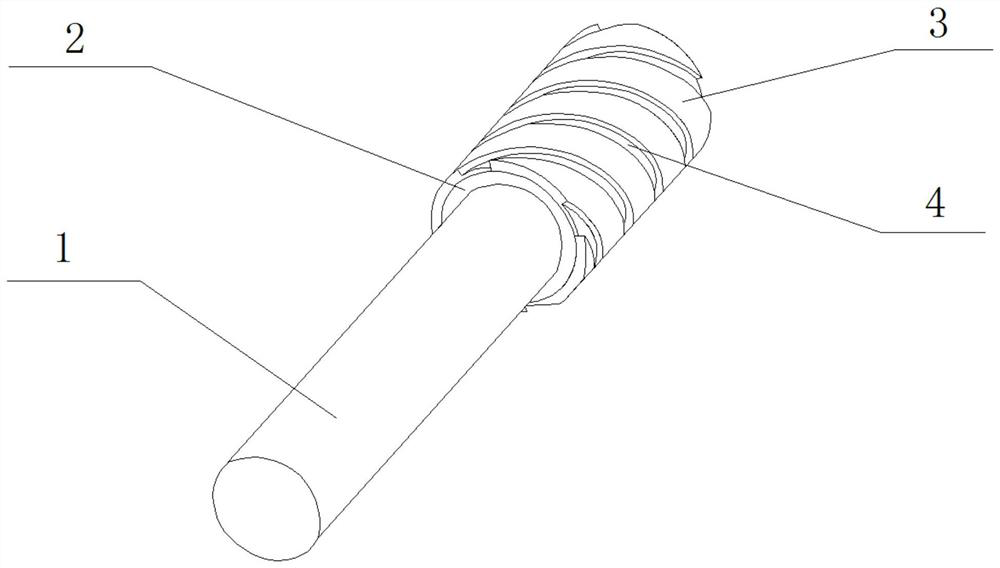

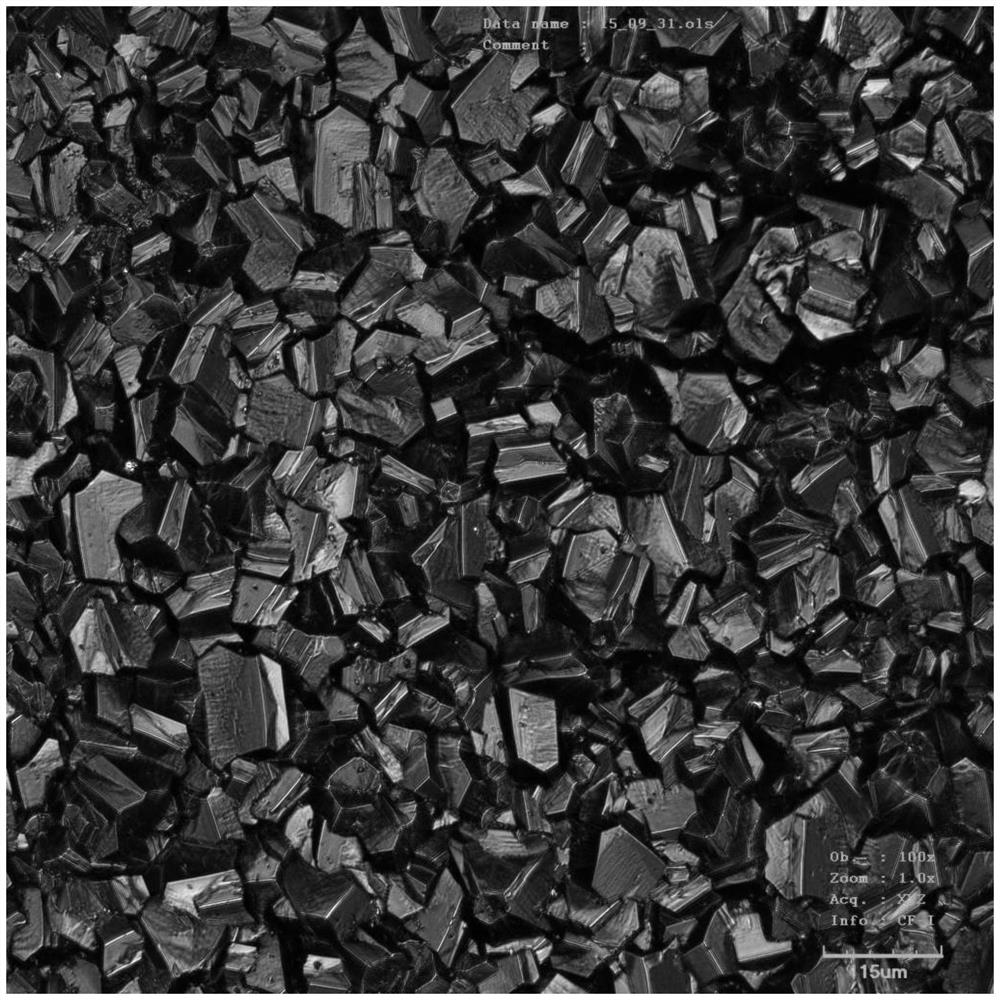

[0031] Such as Figure 1-3 As shown, this embodiment provides a tool for ultrasonic vibration machining of the inner wall of a deep small hole, including a handle 1 and a base 2 of the tool, the handle 1 and the base 2 of the tool are an integral cylindrical connection body of different diameters, the The diameter of the tool base 2 is greater than the diameter of the handle 1, the tool base 2 is coated with a CVD diamond coating 3, the thickness of the CVD diamond coating 3 is 150 μm, and the diamond abrasive grains on the surface of the CVD diamond coating 3 The size is 0.5-10 μm, the CVD diamond coating 3 is provided with a spiral groove 4, the width of the spiral groove 4 is 300 μm, and the depth is more than 20 μm, and the cross section of the spiral groove 4 is rectangular , the pitch of the helical groove 4 is 1 mm, the angle between the helical groove 4 and the end face of the tool base 2 is 45°, and the material of the tool handle 1 and the tool base 2 is SiC; The di...

Embodiment 2

[0037] like Figure 1-3 As shown, this embodiment provides a tool for ultrasonic vibration machining of the inner wall of a deep small hole, including a handle 1 and a base 2 of the tool, the handle 1 and the base 2 of the tool are an integral cylindrical connection body of different diameters, the The diameter of the tool substrate 2 is greater than the diameter of the handle 1, the tool substrate 2 is coated with a CVD diamond coating 3, the thickness of the CVD diamond coating 3 is 100 μm, and the diamond abrasive grains on the surface of the CVD diamond coating 3 The size is 0.5-10 μm, the CVD diamond coating 3 is provided with a helical groove 4, the width of the helical groove 4 is 200 μm, and the depth is 20 μm or more, and the cross section of the helical groove 4 is rectangle, the pitch of the spiral groove 4 is 0.5 mm, the angle between the spiral groove 4 and the end surface of the tool base 2 is 30°, and the material of the handle 1 and the tool base 2 are both Si...

Embodiment 3

[0043] like Figure 1-3 As shown, this embodiment provides a tool for ultrasonic vibration machining of the inner wall of a deep small hole, including a handle 1 and a base 2 of the tool, the handle 1 and the base 2 of the tool are an integral cylindrical connection body of different diameters, the The diameter of the tool base 2 is greater than the diameter of the handle 1, the tool base 2 is coated with a CVD diamond coating 3, the thickness of the CVD diamond coating 3 is 50 μm, and the diamond abrasive grains on the surface of the CVD diamond coating 3 The size is 0.5-10 μm, the CVD diamond coating 3 is provided with a helical groove 4, the width of the helical groove 4 is 150 μm, and the depth is 20 μm or more, and the cross section of the helical groove 4 is rectangular, the pitch of the spiral groove 4 is 1.5mm, the angle between the spiral groove 4 and the end surface of the tool base 2 is 60°, and the material of the tool handle 1 and the tool base 2 are both SiC; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com