Anti-falling cutting pick with composite assembled structure

A combined assembly and anti-shedding technology, which is applied in the field of picks, can solve the problems of pick heads falling off and being scrapped, and achieve the effects of improving anti-shedding ability, excellent performance and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

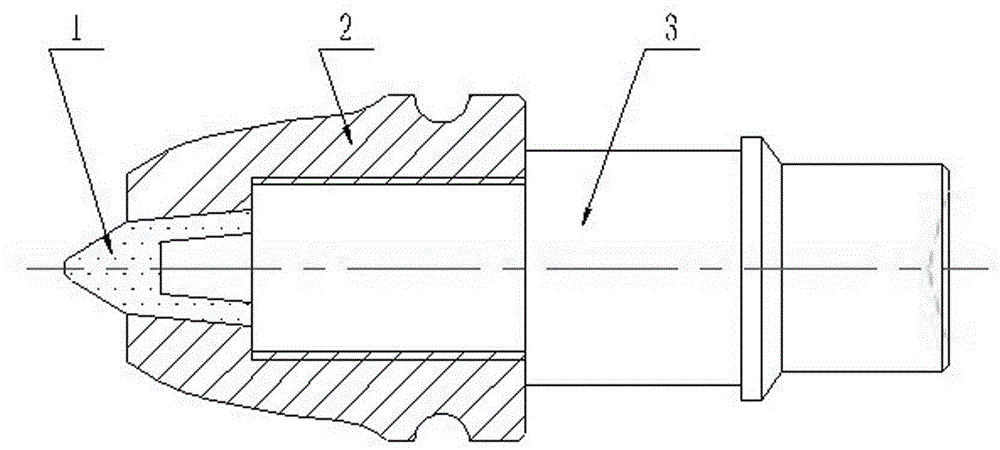

[0017] like figure 1 As shown, an anti-falling pick with combined assembly structure of the present invention includes a pick shank 3 , a pick head 1 , and a protective fixing sleeve 2 . The pick head 1 and the pick shank 3 are connected by self-locking Morse taper, the pick head 1 is an inner taper hole, and the pick shank 3 is an outer taper shank; the protective fixing sleeve 2 and the pick head 1 also adopt self-locking Morse taper Taper connection, the pick head 1 is an outer tapered shank, the protective fixing sleeve 2 is an inner tapered hole; the protective fixing sleeve 2 and the pick shank 3 are threaded. Pick head 1 is a hard alloy pick head

Embodiment 2

[0019] like figure 1 As shown, an anti-falling pick with combined assembly structure of the present invention includes a pick shank 3 , a pick head 1 , and a protective fixing sleeve 2 . The pick head 1 and the pick shank 3 are connected by a self-locking standard metric taper, the pick head 1 is an inner taper hole, and the pick shank 3 is an outer taper shank; the protective fixing sleeve 2 and the pick head 1 also adopt a self-locking standard metric system Taper connection, the pick head 1 is an outer tapered shank, the protective fixing sleeve 2 is an inner tapered hole; the protective fixing sleeve 2 and the pick shank 3 are threaded. The pick head 1 is a diamond pick head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com