Pneumatic pump control device

A technology for control devices and pneumatic pumps, applied in pump control, pumps, piston pumps, etc., can solve the problems of increasing operating costs, reducing pump life, wasting compressed air power sources, etc., to improve service life, reduce start-stop frequency, The effect of optimized working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

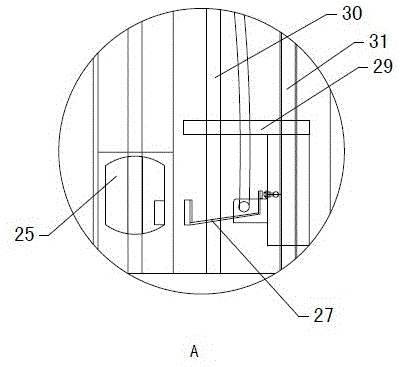

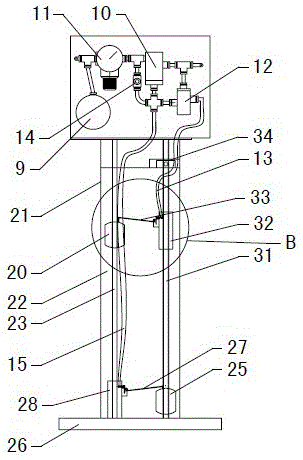

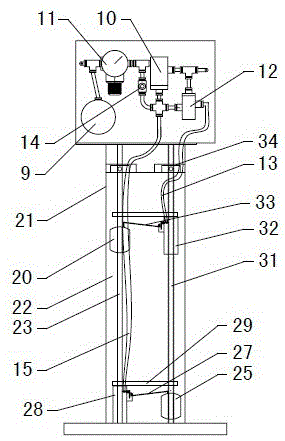

[0040] Figure 1~3 It is the best embodiment of the pneumatic pump control device. Figure 1~6 The present invention will be further explained.

[0041] The pneumatic pump control device includes a pneumatic pump 5, an air supply pipeline 1, an air supply air control valve 3, and a control pipeline 7. The air supply pipeline 1 provides an air source for the pneumatic pump 5; the air supply air control valve 3 is set in the air supply pipe On line 1, control the on and off of the air supply line 1; the inlet of the control line 7 is connected to the air supply line 1 on the front side of the air supply air control valve 3, and the outlet is connected to the control air inlet of the air supply air control valve 3; control line 7 It is provided with a first control air control valve 10 and a second control air control valve 12, and also includes a low liquid level detection mechanism 19 and a high liquid level detection mechanism 18, which are connected to the first control air cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com