Ultrasonic underwater target thickness measuring system and thickness measuring method

An underwater target and thickness measurement technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problem that ultrasonic thickness gauges do not have the ability to detect the thickness of underwater targets, and achieve accurate measurement and promotion sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

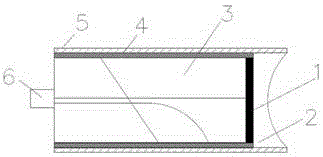

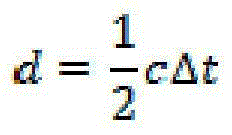

[0020] Ultrasonic underwater target thickness measurement system is based on the principle of ultrasonic pulse reflection to measure thickness. When the ultrasonic pulse emitted by the probe is transmitted to the underwater measured object and reaches the material interface, the pulse is reflected back to the probe, and the thickness of the measured material can be determined by accurately measuring the time the ultrasonic wave travels in the material. All kinds of materials that can make ultrasonic waves propagate inside them at a constant speed can be measured by this principle.

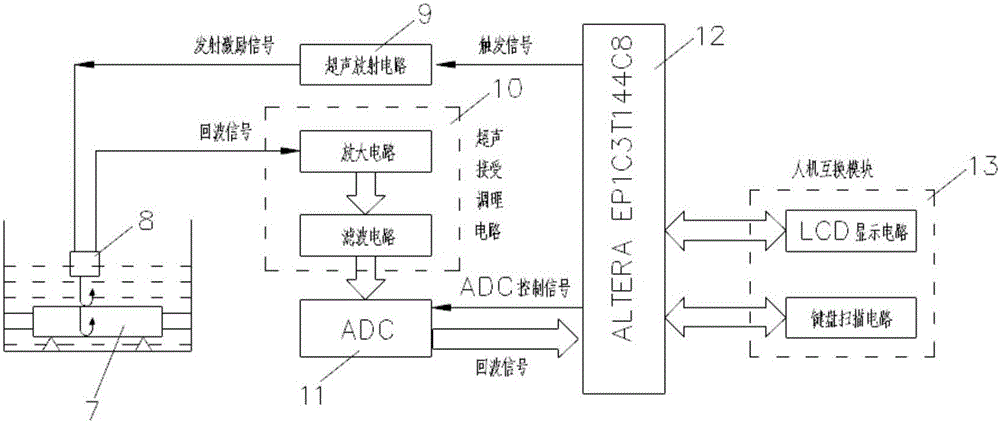

[0021] Such as figure 2 The structural block diagram of the ultrasonic underwater target thickness measurement system is shown. The system includes an ultrasonic transmitting circuit 9 , an ultrasonic transducer 8 , an ultrasonic receiving and conditioning circuit 10 , an ADC module 11 , a human-computer interaction module 13 and a control processor 12 . The control processor 12 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com