A rolling bearing condition monitoring method

A rolling bearing and status technology, applied in the field of status monitoring and fault diagnosis of rotating machinery, can solve problems such as poor noise resistance and robustness, difficulty in timely and accurately detecting early faults of rolling bearings, large errors, etc., to achieve good noise resistance and Robustness, simplification of dynamic analysis process, effect of noise removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

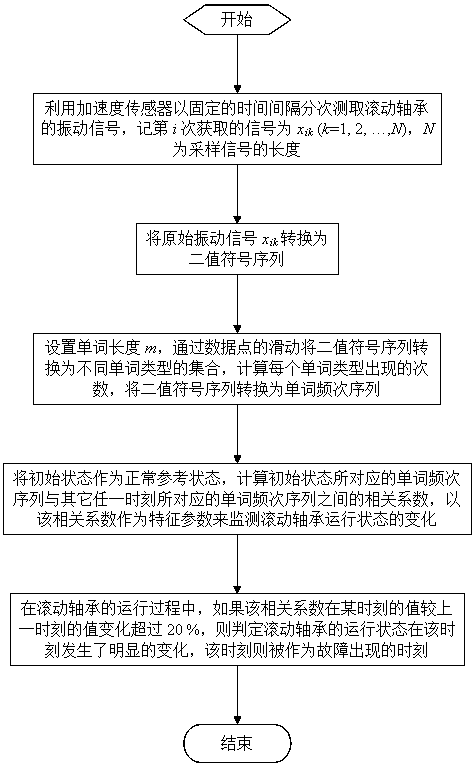

[0027] Examples such as figure 1 As shown, a rolling bearing condition monitoring method is implemented according to the following steps:

[0028] 1) Use the acceleration sensor to measure the vibration signal of the rolling bearing at fixed time intervals, and record the signal acquired for the ith time as x ik (k=1, 2, ..., N), N is the length of the sampling signal; the time interval is generally 10 minutes;

[0029] 2) According to the rising or falling relationship between adjacent sequence points, the sequence x ik Convert to sequence of binary symbols ,

[0030] ,

[0031] 3) Define m consecutive characters as a word, convert the binary symbol sequence into a set containing different word types by sliding the data points, calculate the frequency of occurrence of each word type, and finally get a length of 2 m The frequency sequence of words; generally set m=8;

[0032] 4) Taking the initial state as the normal reference state, calculate the correlation coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com