Device and method for automatically detecting lens defects through modulation by optical grating

An automatic detection device and grating technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

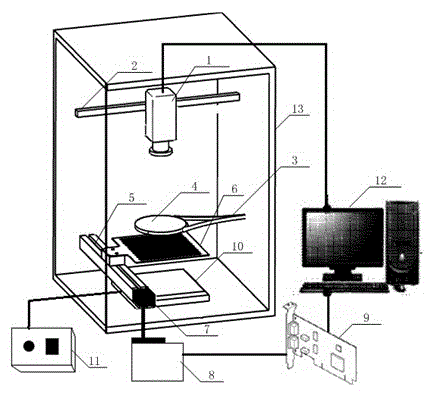

[0026] Introduce detailed technical scheme of the present invention below in conjunction with accompanying drawing: as figure 1 As shown, a grating-modulated lens defect automatic detection device includes an image acquisition device 1, a camera fixing frame 2, a lens fixing frame 3, a lens to be inspected 4, a linear screw guide rail 5, a grating 6, a stepping motor 7, Motor driver 8, motion control card 9, planar backlight source 10, light source controller 11, main controller 12, camera obscura 13 and image acquisition, image acquisition device 1 is vertically fixed on the top of the device through camera holder 2, and through USB3.0 The interface is connected to the main controller 12, and the image acquisition device 1 is on the same vertical plane as the center line of the inspected lens 4, the grating 6 and the plane light source 10; the inspected lens 4 is fixed parallel to the image acquisition device 1 through the lens holder 5 Between and the grating 6; the grating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com