Design and evaluation method of a detector structure high overload tightening test

A technology of test design and detectors, which is applied in the fields of instruments, calculations, and special data processing applications, etc., can solve the problems that there is no comprehensive reliability verification scheme specifically proposed, and there are few researches on the reliability of bomb detector structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described in detail below in conjunction with examples.

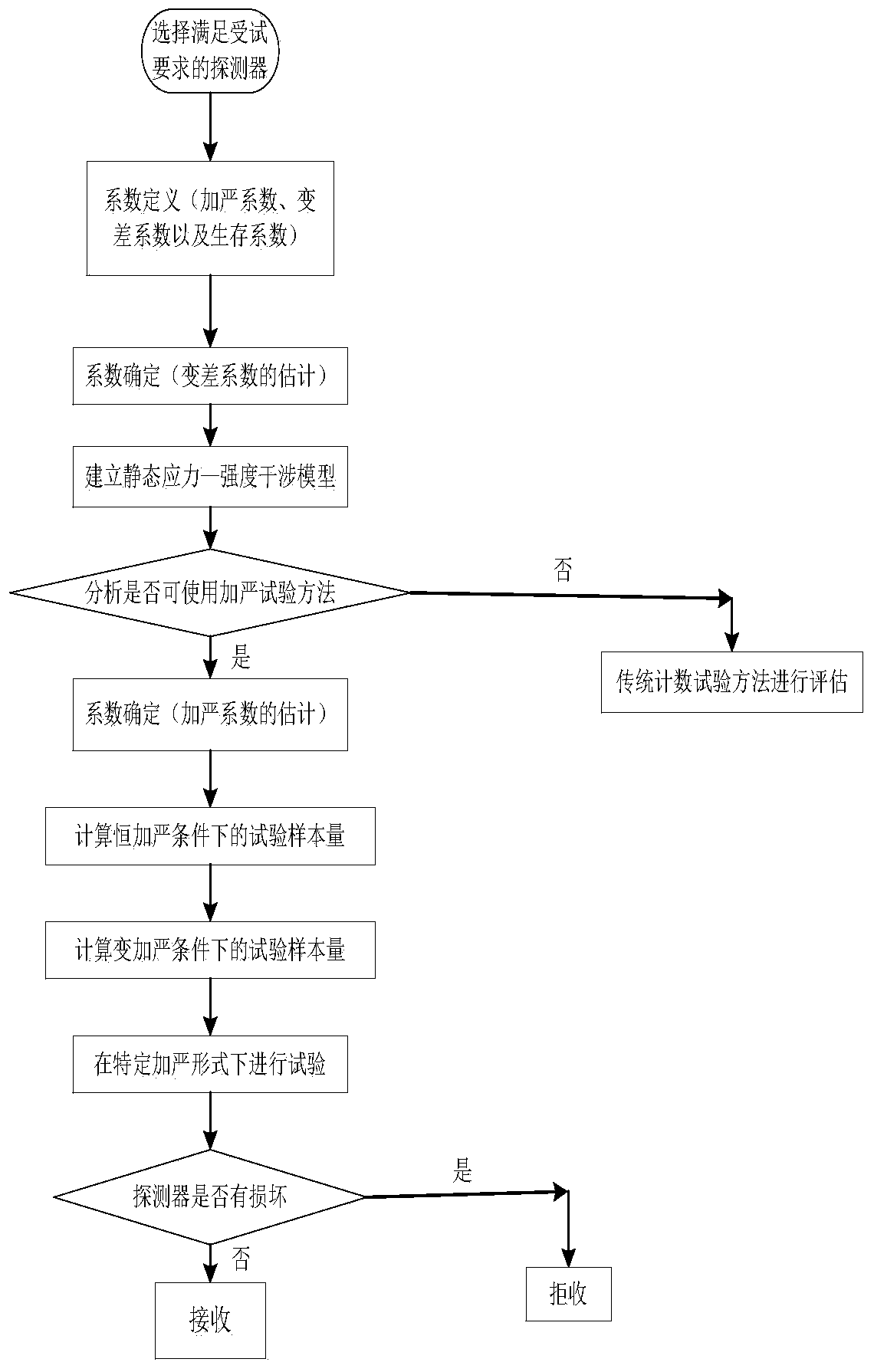

[0097] See figure 1 , a method for designing and evaluating a detector structure high overload tightening test of the present invention, which is realized through the following steps:

[0098] Step 1: Estimate the coefficient of variation

[0099] If the mean and variance of strength and stress are measured for 20 detector structures, it is assumed that the measured mean and variance are shown in the following table:

[0100] Table 2 Measured value of stress intensity

[0101] category

Average (×1000g)

Standard deviation (×1000g)

sample size

stress

30

4.5

0.15

10

strength

50

5.0

0.1

10

[0102] Step 2: Calculate the test sample size under the condition of constant tightening

[0103] If 1-α=0.9, the reliability index is required to reach R L =0.999, calculate formula (11), obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com