Novel insert core interlocking mechanism

An interlocking mechanism and ferrule technology, applied in switchgear, pull-out switchgear, electrical components, etc., can solve the problems of large occupied space, hidden safety hazards for operators, difficult installation and maintenance, etc., and achieve convenient disassembly and assembly. , the effect of small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

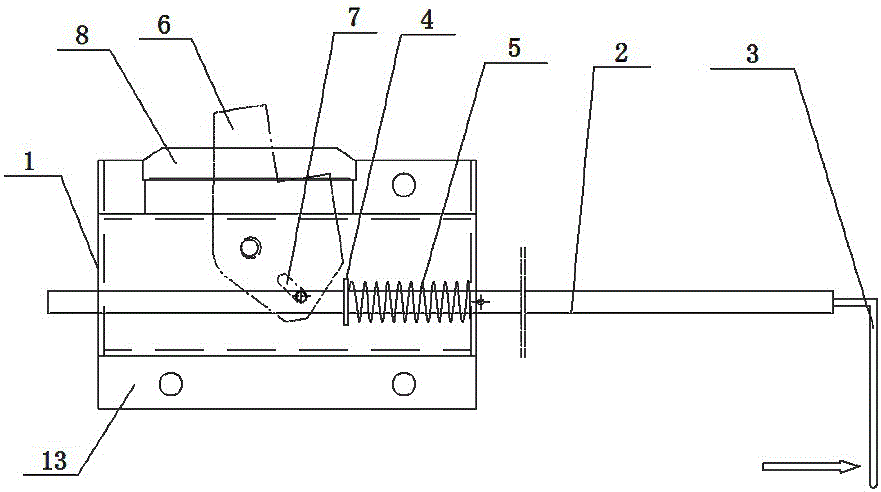

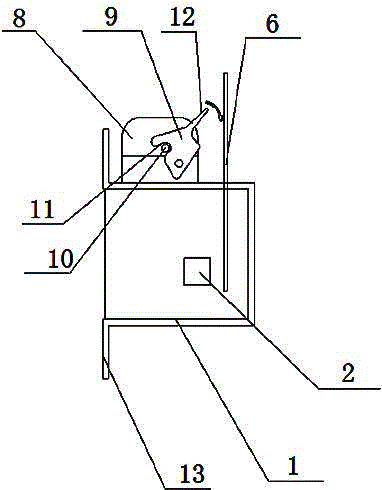

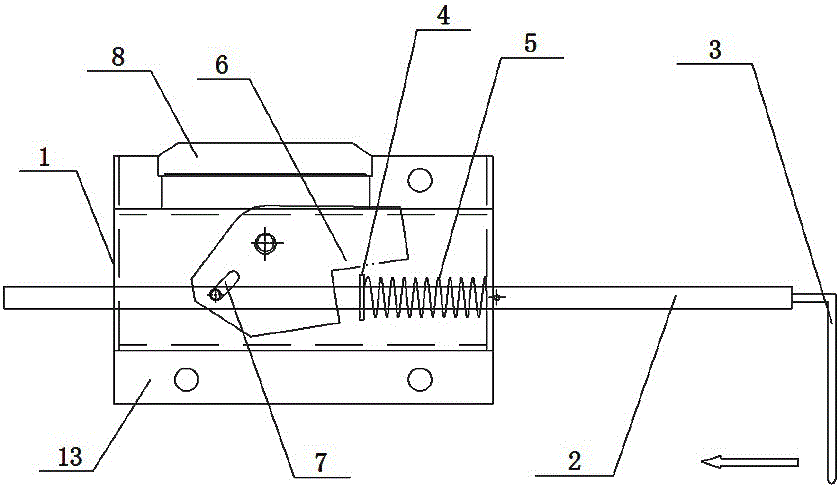

[0015] Such as figure 1 As shown, the new mortise interlock mechanism includes a housing 1. A telescopic rod 2 is interspersed in the axial direction of the housing 1. The direction in which the handcart moves to the working position is the front. The telescopic rod 2 There is a hanging plate 3 at the front end of the handcart. When the handcart moves to the working position, the hanging plate 3 will block the handcart, so that the hanging plate 3 and the handcart move forward together. The telescopic rod 2 is provided with a raised part 4 The telescopic rod 2 at the front end of the raised portion 4 is fitted with a return spring 5, the raised portion 4 blocks the rear end of the return spring 5, the return spring 5 is located in the housing 1, and the front side wall of the housing 1 blocks the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com