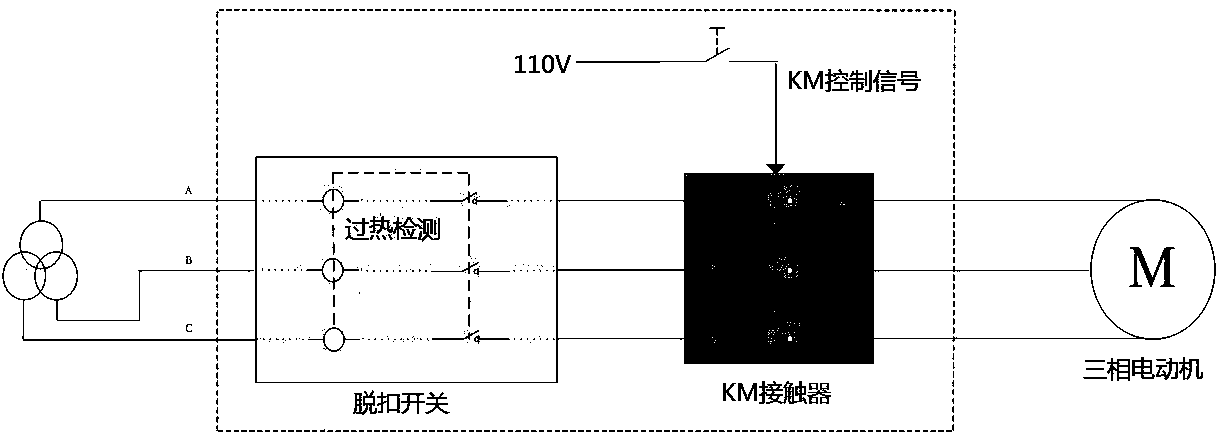

Protector for three-phase motor of alternating-current or direct-current electric locomotive

A three-phase motor, electric locomotive technology, applied in emergency protection circuit devices, electrical components and other directions, can solve the problems of lack of information, low overheat detection accuracy, insufficient flexibility, etc., to achieve convenient installation and maintenance, convenient analysis and processing , the effect of convenient unified management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

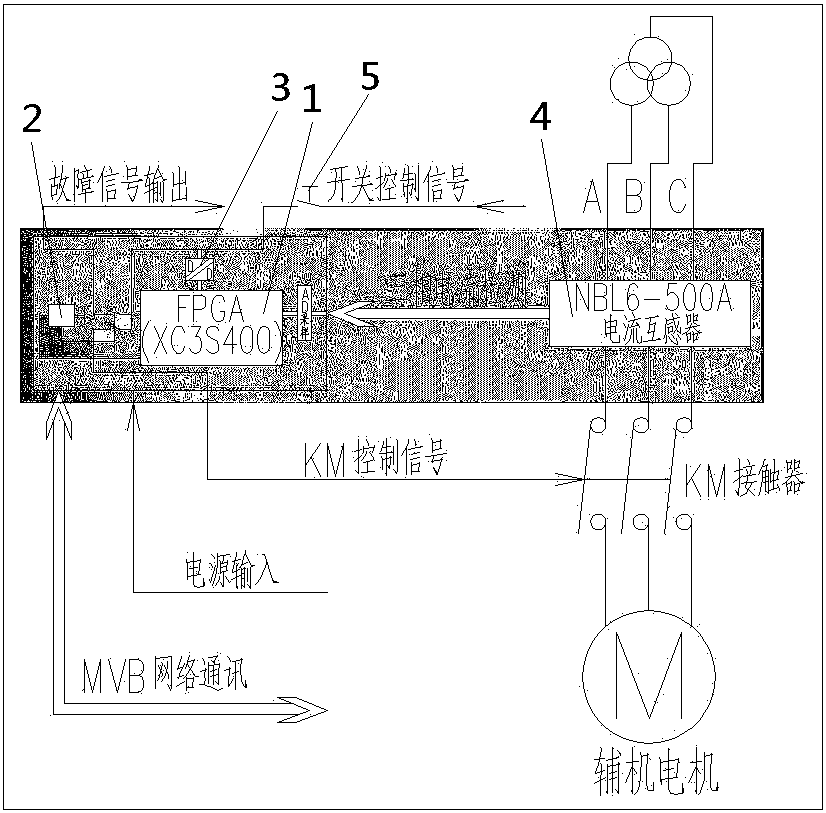

[0042] Such as figure 2 As shown, a three-phase motor protector for AC and DC electric locomotives includes a current transformer 4 and a KM contactor connected in series on a three-phase motor branch circuit, and also includes a control switch 5, a data processing chip 1, a relay 2 and a switch signal Collector 3; The current transformer 4, relay 2 and switch signal collector 3 are all electrically connected to the data processing chip 1. The relay 2 whose input terminal is electrically connected to the control switch 5 is electrically connected to the normally closed node of the KM contactor, The normally open node is electrically connected to the fault signal output circuit; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com