Sensor and manufacture method of the sensor

A manufacturing method and sensor technology, which are applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of inability to efficiently sense dynamic images and low carrier mobility of amorphous silicon materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

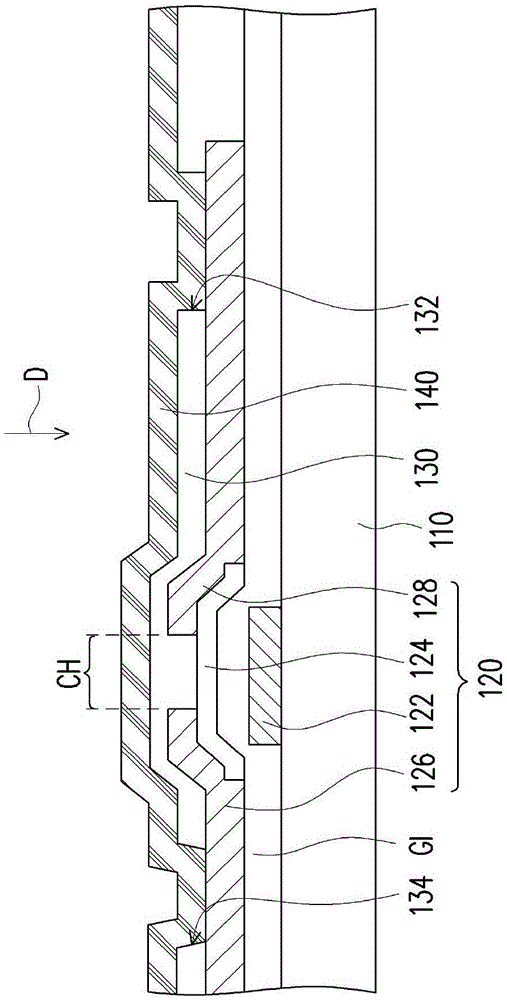

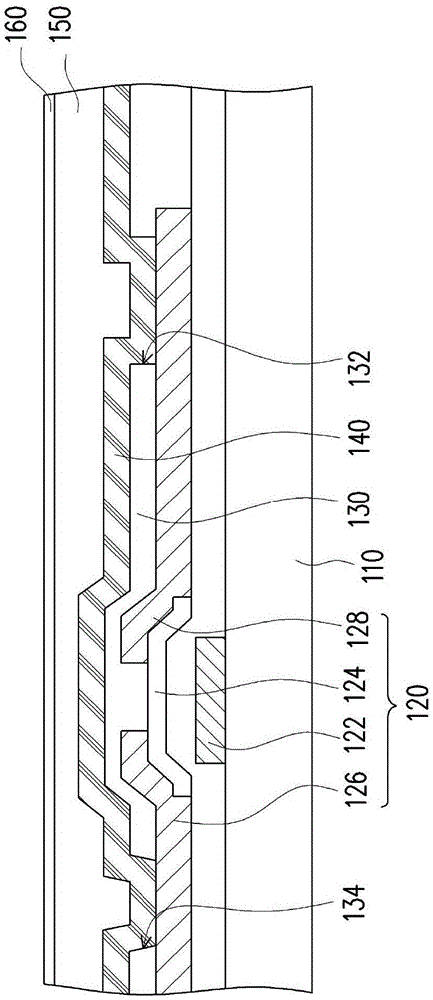

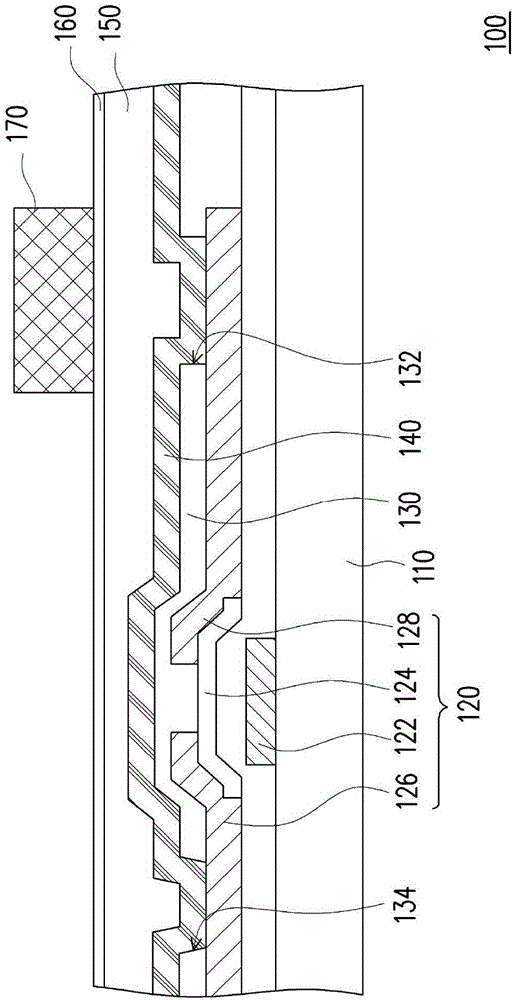

[0047] Figure 1A to Figure 1F It is the manufacturing method of the sensor of the first embodiment of the present invention. First, by Figure 1A It can be seen that the active device 120 is formed on the substrate 110 , where the active device 120 is, for example, a thin film transistor in this embodiment, and the active device 120 includes a gate 122 , a channel layer 124 , a source 126 and a drain 128 . The gate 122 is located between the channel layer 124 and the substrate 110 , and a gate insulating layer GI is disposed between the gate 122 and the channel layer 124 to avoid direct conduction between the two. Moreover, both the source electrode 126 and the drain electrode 128 are in contact with the channel layer 124 and are separated by a distance on the channel layer 124 to define the channel region CH. The above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com