Pulse-forming line with reentry structure

A pulsed and reentrant technology, applied in the direction of electrical pulse generator circuits, etc., can solve the problems of huge system and high engineering difficulty, and achieve the effect of high energy transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with specific implementation examples.

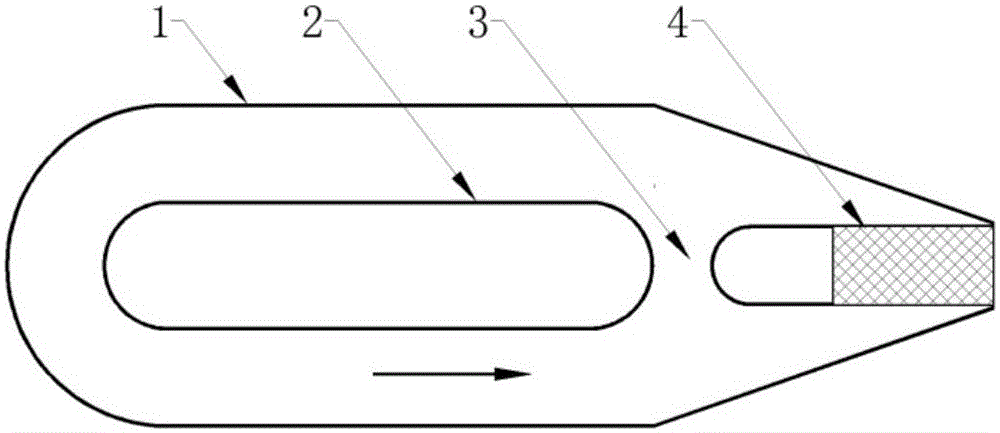

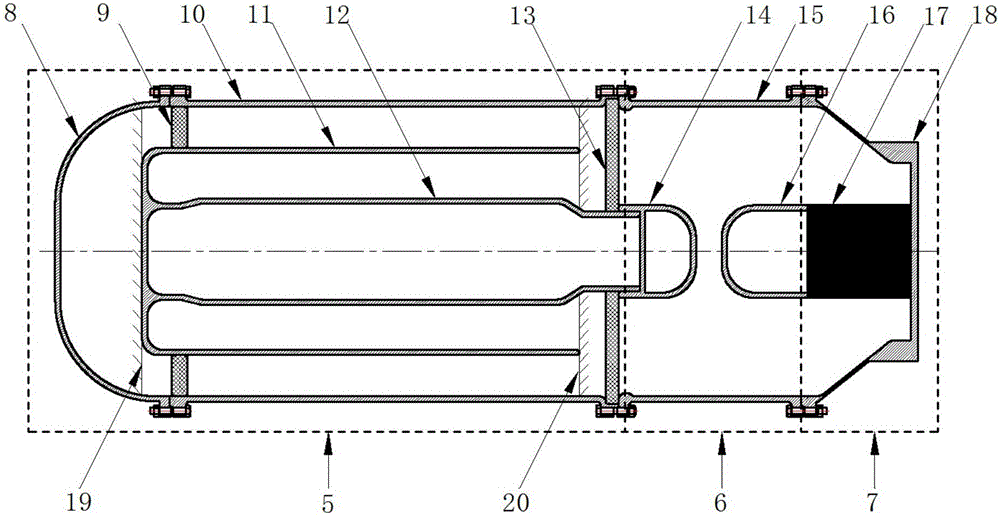

[0019] See figure 1 — figure 2 , The present invention includes the reentry pulse forming line segment 5, the switch segment 6 and the load segment 7.

[0020] The reentry forming line segment 5 is composed of three metal cylinders and an insulating filling medium. The three coaxial metal cylinders include an outer cylinder 10, a middle cylinder 11 and an inner cylinder 12. The three metal cylinders are sleeved together The left end of the outer cylinder 10 and the back cover 8 are connected by flange electrical contact, the right end of the outer cylinder 10 and the left end of the switch outer cylinder 15 are connected by flange electrical contact, and the left end of the middle cylinder 11 is in electrical contact with the left end of the inner cylinder 12 Connected or directly integrated processing, not connected to the back cover 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com