Jet-flow water heater

A heater and jet type technology, which is applied in the field of fish tank water body heating appliances, can solve the problems of low thermal efficiency and non-disassembly, and achieve the effects of high thermal efficiency, improved energy efficiency ratio, and easy product maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be implemented in the following ways:

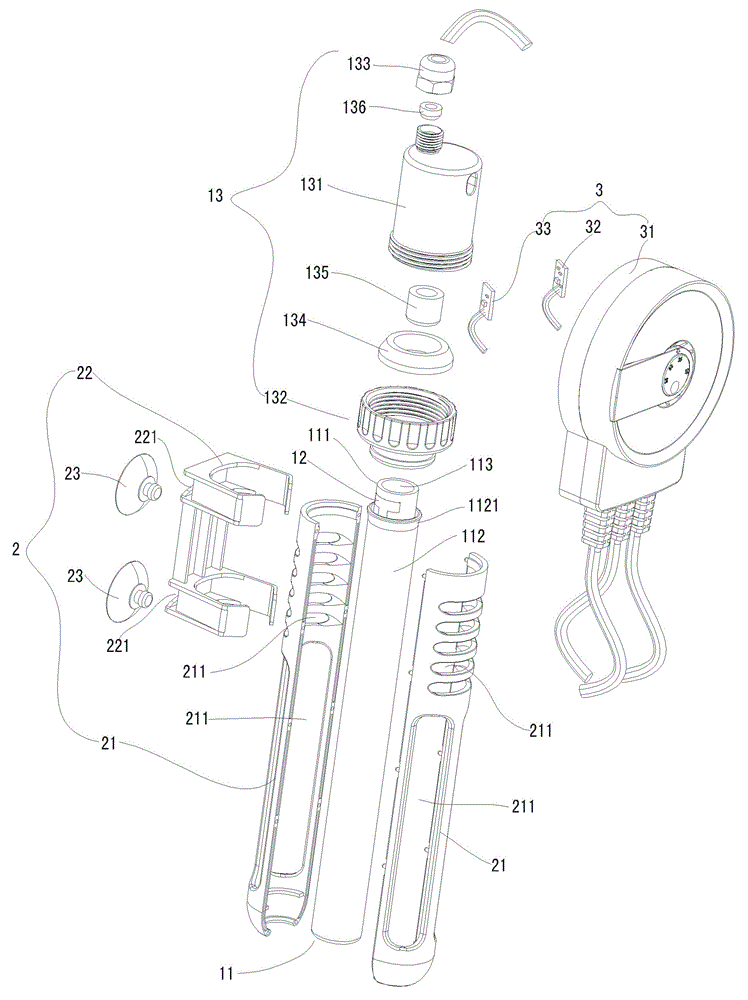

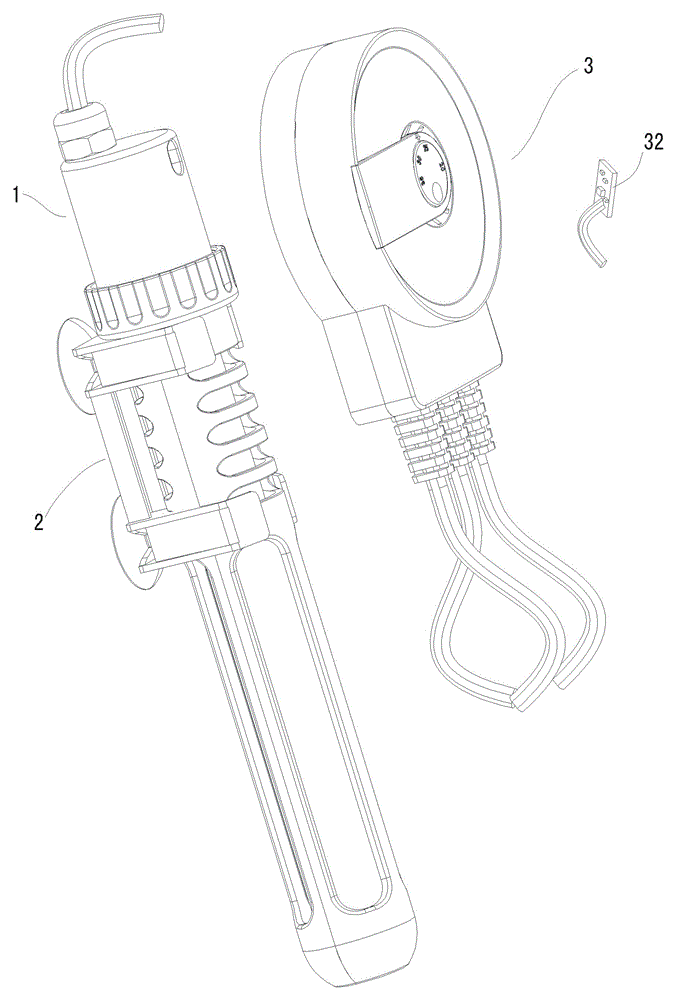

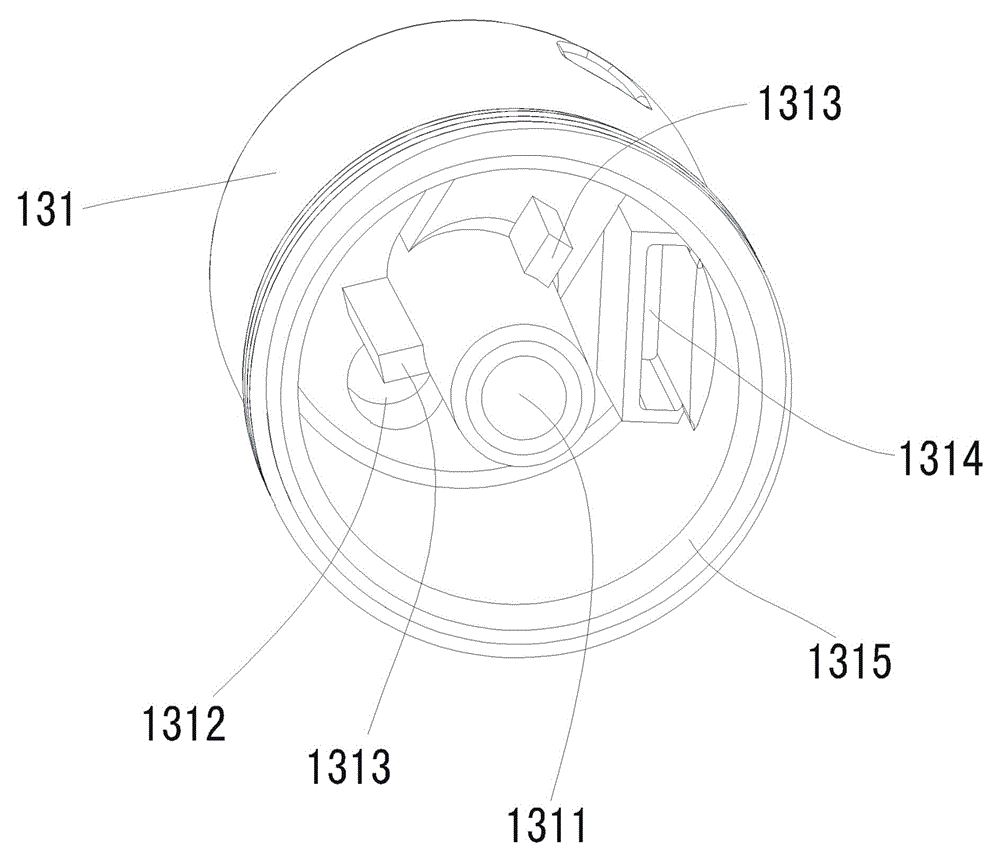

[0029] Such as figure 1 , figure 2 As shown, the present invention includes a heating rod main assembly 1, a bracket assembly 2 and a temperature control assembly 3; the heating rod main assembly 1 includes a double-layer quartz tube 11, a heating film 12 and a water spray joint 13, and one end of the double-layer quartz tube 11 is closed, The other end is provided with an opening, and the heating film 12 is attached to the outer wall of the inner tube 111, and the inner side of the inner tube 111 is set as a thermal fluid channel 113; the water spray joint 13 is arranged at the opening end of the double-layer quartz tube 11, including a joint cavity 131, Connector cover 132, power cord cover 133, wedge-shaped sealing ring 134, inner runner sealing plug 135 and power cord sealing plug 136, bracket assembly 2 includes convection cover 21, bracket 22 and suction cup 23, convection cover 21 is covered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com