Control system for hydraulic system and method for recovering energy and leveling hydraulic system loads

A technology of pressure and summation, which is applied in the field of hydraulic systems and can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Aspects of the invention illustrated in the accompanying drawings will now be described in detail. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like structures.

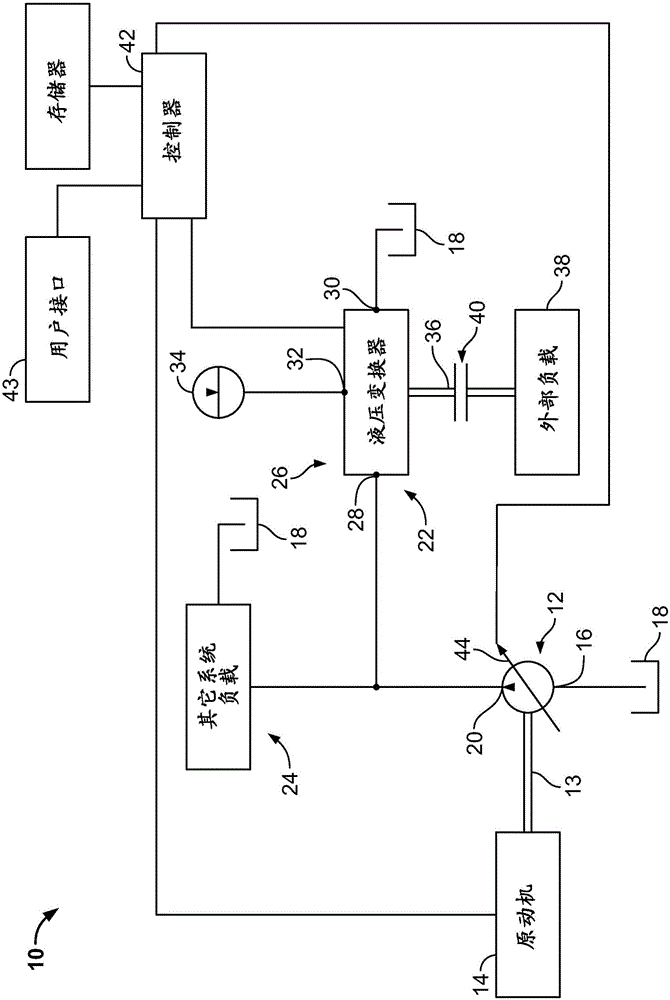

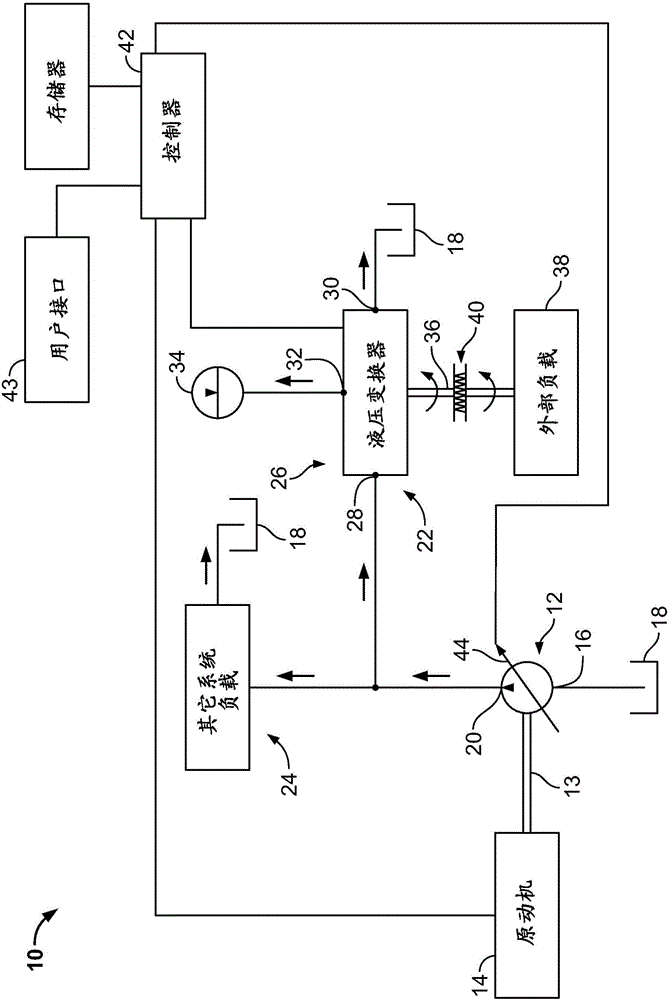

[0032] figure 1 A system 10 in accordance with the principles of the present invention is shown. System 10 includes a variable displacement pump 12 driven by a prime mover 14 (eg, a diesel engine, spark ignition engine, electric motor, or other power source). The variable displacement pump 12 includes an inlet 16 that draws low pressure hydraulic fluid from a tank 18 (ie, a low pressure reservoir). The variable displacement pump 12 also includes an outlet 20 through which high pressure hydraulic fluid exits. Outlet 20 is preferably fluidly coupled to a plurality of different workload circuits. For example, outlet 20 is shown coupled to a first load circuit 22 and a second load circuit 24 . The first load circuit 22 includes a hydraulic transduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com