A kind of millet seeding control method

A technology of seeding rate and millet, applied in shovels, ploughs, agricultural machinery and implements, etc., can solve the problems of poor farmers' purchasing power and low operation efficiency, and achieve the effect of high operation efficiency, low cost and improved annual utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: spring sowing small group planting pattern; Concrete steps are:

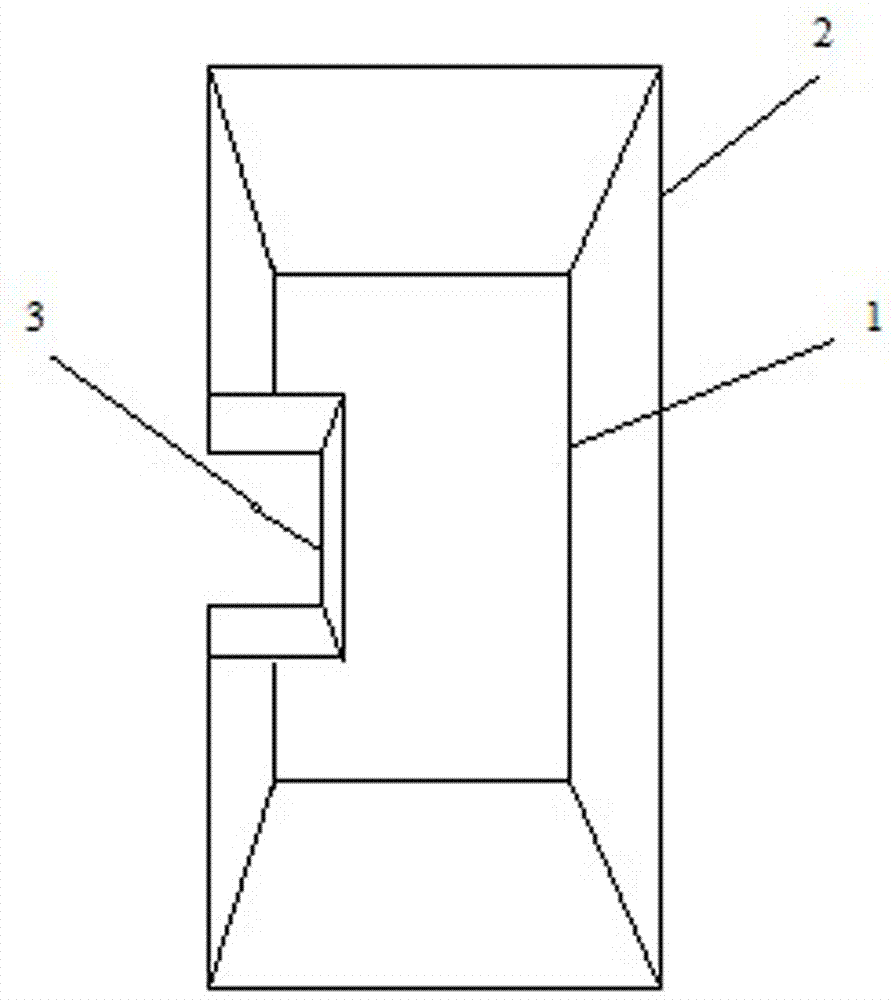

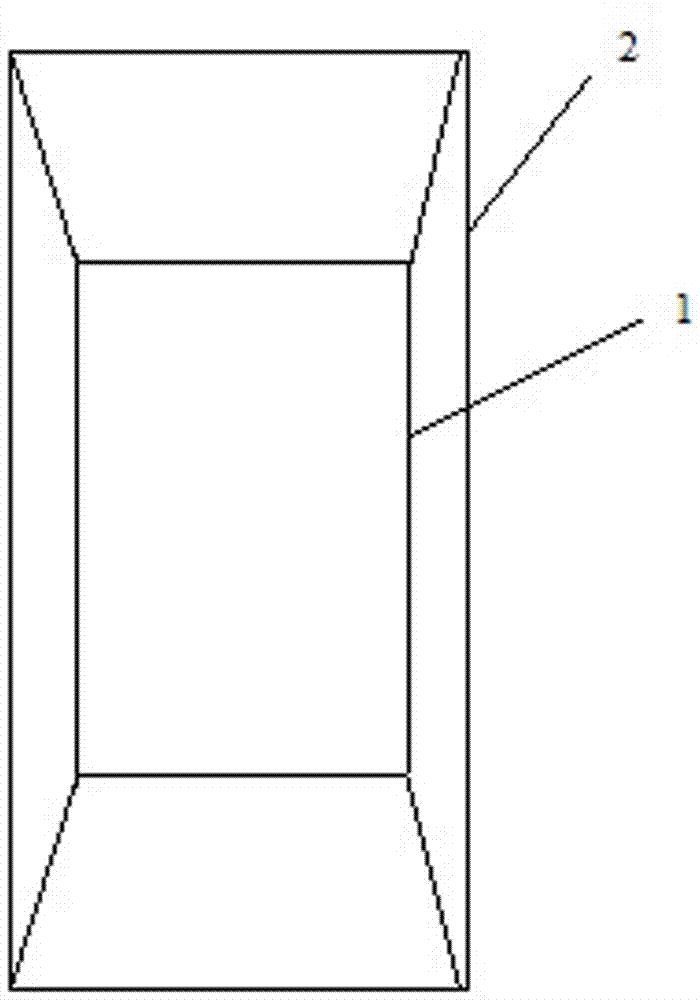

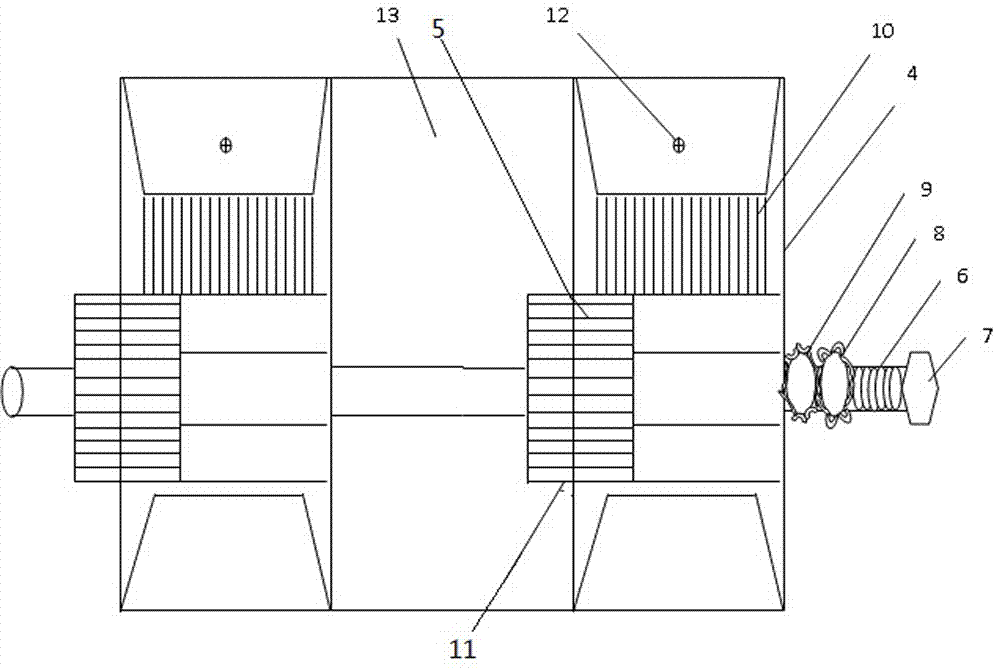

[0023] (1) Make the seeding box cover; use polystyrene foam to make the seeding box cover; the seeding box cover includes the seeding box cover A, the seeding box cover B; the seeding box cover A, the seeding box cover B They are all trapezoidal structures, the lower bottom (1) is small, and the upper bottom (2) is large; the middle part of one side of the seeding box cover A is provided with a lower seeding hole (3) passing through the upper and lower bottoms; the seeding box cover B Then there is no seeding hole (3); the seeding box cover A is buckled on the seeding box (4) used for sowing and lowering seeds in the seed box of the wheat rotary tillage, sowing and suppressing all-in-one machine, and the seeding box cover B is buckled on the wheat rotary. On the seed box (4) in the seed box of the all-in-one plowing, seeding and pressing machine that does not need to sow seeds; use adhesive ...

Embodiment 2

[0031] Embodiment 2: Wheat stubble re-sows large group planting pattern; Concrete steps are:

[0032] (1) Make the seeding box cover; use polystyrene foam to make the seeding box cover; the seeding box cover includes the seeding box cover A, the seeding box cover B; the seeding box cover A, the seeding box cover B They are all trapezoidal structures, the lower bottom (1) is small, and the upper bottom (2) is large; the middle part of one side of the seeding box cover A is provided with a lower seeding hole (3) passing through the upper and lower bottoms; the seeding box cover B Then there is no seeding hole (3); the seeding box cover A is buckled on the seeding box (4) used for sowing and lowering seeds in the seed box of the wheat rotary tillage, sowing and suppressing all-in-one machine, and the seeding box cover B is buckled on the wheat rotary. On the seed box (4) in the seed box of the all-in-one plowing, seeding and pressing machine that does not need to sow seeds; use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com