A self-propelled notoginseng harvester

A harvester and self-propelled technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of high cost of working hours and heavy labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

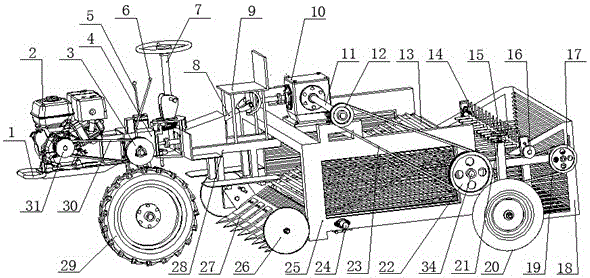

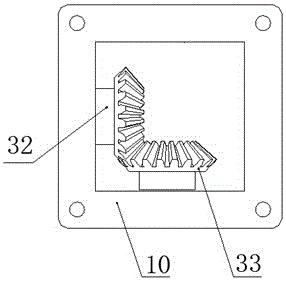

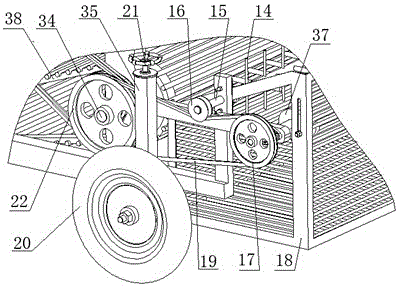

[0028] Embodiment 1: as Figure 1-7 As shown, a self-propelled notoginseng harvester includes a walking system, an excavating device, a sieve elevator, a vibrating collection box, a cross shaft universal joint 8, a seat 9, a reversing gear box 10, and a drive shaft 11. Pulley III12, tension pulley 16, pulley IV17, belt III19, auxiliary wheel 20, adjustment handwheel 21, pulley V22, belt II23, frame 25, connecting frame 28, adjustment screw 35; The walking system is positioned at the front of the frame 25, and is connected with the frame 25 through a connecting frame 28. The upper front end of the frame 25 is provided with a reversing gear box 10, and the bottom is equipped with an excavating device. The vibration type collection box is articulated behind the type elevator; the connecting frame 28 is provided with a seat 9, and the power output shaft 47 of the walking gear box 4 is connected with the reversing gear box 10 through the cross shaft universal joint 8; The rear of ...

Embodiment 2

[0039] Embodiment 2: as Figure 1-7 As shown, a self-propelled notoginseng harvester includes a walking system, an excavating device, a sieve elevator, a vibrating collection box, a cross shaft universal joint 8, a seat 9, a reversing gear box 10, and a drive shaft 11. Pulley III12, tension pulley 16, pulley IV17, belt III19, auxiliary wheel 20, adjustment handwheel 21, pulley V22, belt II23, frame 25, connecting frame 28, adjustment screw 35; The walking system is positioned at the front of the frame 25, and is connected with the frame 25 through a connecting frame 28. The upper front end of the frame 25 is provided with a reversing gear box 10, and the bottom is equipped with an excavating device. The vibration type collection box is articulated behind the type elevator; the connecting frame 28 is provided with a seat 9, and the power output shaft 47 of the walking gear box 4 is connected with the reversing gear box 10 through the cross shaft universal joint 8; The rear of ...

Embodiment 3

[0049] Embodiment 3: as Figure 1-7 As shown, a self-propelled notoginseng harvester includes a walking system, an excavating device, a sieve elevator, a vibrating collection box, a cross shaft universal joint 8, a seat 9, a reversing gear box 10, and a drive shaft 11. Pulley III12, tension pulley 16, pulley IV17, belt III19, auxiliary wheel 20, adjustment handwheel 21, pulley V22, belt II23, frame 25, connecting frame 28, adjustment screw 35; The walking system is positioned at the front of the frame 25, and is connected with the frame 25 through a connecting frame 28. The upper front end of the frame 25 is provided with a reversing gear box 10, and the bottom is equipped with an excavating device. The vibration type collection box is articulated behind the type elevator; the connecting frame 28 is provided with a seat 9, and the power output shaft 47 of the walking gear box 4 is connected with the reversing gear box 10 through the cross shaft universal joint 8; The rear of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com