A single crawler notoginseng combine harvester

A combine harvester and Panax notoginseng technology, which is applied to digging harvesters, harvesters, topping machines, etc., can solve the problems of heavy labor and high cost of working hours, achieve a high degree of automation, ensure integrity, and solve the problem of digging difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

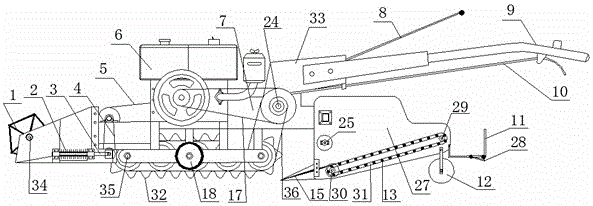

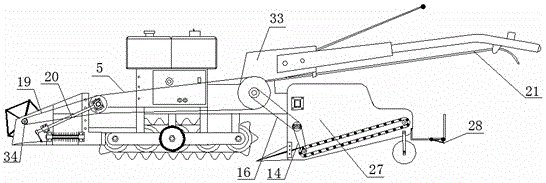

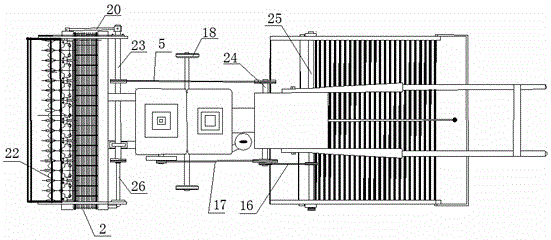

[0030] Embodiment 1: as Figure 1-6 As shown, a single crawler notoginseng combine harvester includes a power unit, a stalk cutting and laying device, an excavating device, a soil clearing device, and a collection device; the power unit includes a diesel engine 6 and a handrail 9; On the diesel engine frame 7, power is provided for cutting stems, stem laying, excavation, and soil clearing; the stem cutting and laying device is installed at the front end of the diesel engine frame 7 and at the rear of the diesel engine frame Mount the excavation frame 27, the front end of the excavation frame 27 is equipped with an excavation device, and the rear part is respectively equipped with a soil clearing device and a collection device; the stem cutting and laying device includes a reel 1, a cutter 22 , stalk conveyor belt 2; the reel 1 is installed at the front end of the diesel engine frame 7, the lower part of the reel 1 is provided with a cutter 22, and the end of the cutter 22 near...

Embodiment 2

[0031] Embodiment 2: as Figure 1-6As shown, a single crawler notoginseng combine harvester includes a power unit, a stalk cutting and laying device, an excavating device, a soil clearing device, and a collection device; the power unit includes a diesel engine 6 and a handrail 9; On the diesel engine frame 7, power is provided for cutting stems, stem laying, excavation, and soil clearing; the stem cutting and laying device is installed at the front end of the diesel engine frame 7 and at the rear of the diesel engine frame Mount the excavation frame 27, the front end of the excavation frame 27 is equipped with an excavation device, and the rear part is respectively equipped with a soil clearing device and a collection device; the stem cutting and laying device includes a reel 1, a cutter 22 , stalk conveyor belt 2; the reel 1 is installed at the front end of the diesel engine frame 7, the lower part of the reel 1 is provided with a cutter 22, and the end of the cutter 22 near ...

Embodiment 3

[0034] Embodiment 3: as Figure 1-6 As shown, a single crawler notoginseng combine harvester includes a power unit, a stalk cutting and laying device, an excavating device, a soil clearing device, and a collection device; the power unit includes a diesel engine 6 and a handrail 9; On the diesel engine frame 7, power is provided for cutting stems, stem laying, excavation, and soil clearing; the stem cutting and laying device is installed at the front end of the diesel engine frame 7 and at the rear of the diesel engine frame Mount the excavation frame 27, the front end of the excavation frame 27 is equipped with an excavation device, and the rear part is respectively equipped with a soil clearing device and a collection device; the stem cutting and laying device includes a reel 1, a cutter 22 , stalk conveyor belt 2; the reel 1 is installed at the front end of the diesel engine frame 7, the lower part of the reel 1 is provided with a cutter 22, and the end of the cutter 22 near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com