A gas-liquid distributor for ebullated bed reactor

A fluidized bed reactor, gas-liquid distributor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as wear, large distribution plate openings, check ball disturbance, etc., and achieve aggravated mixing and flow. Smooth and prevent backflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

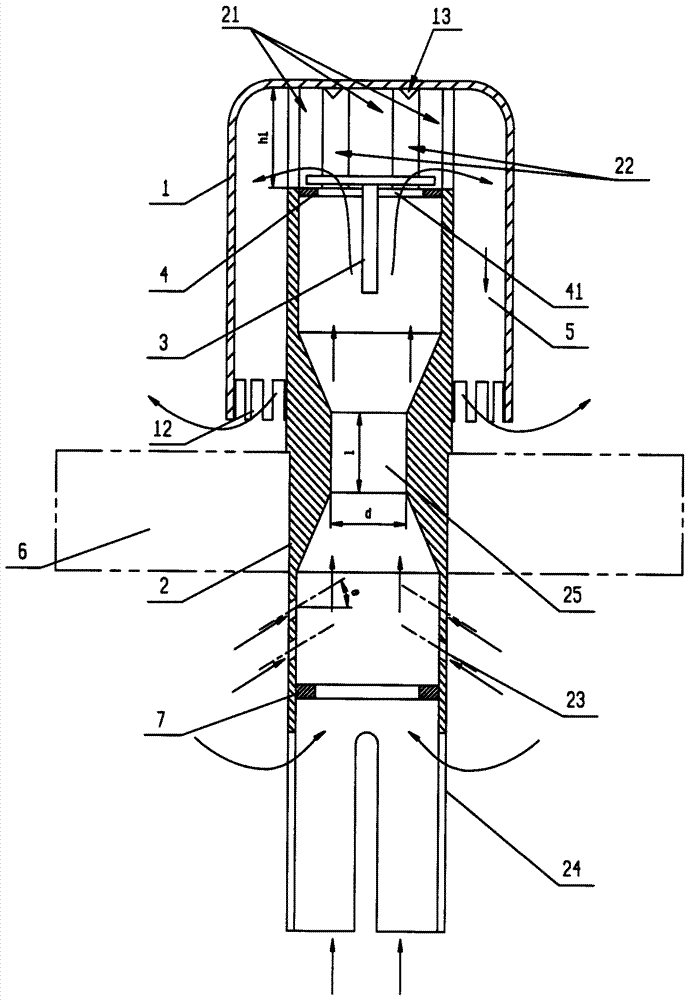

[0027] like figure 1 As shown, a gas-liquid distributor for ebullated bed reactor provided by the present invention is mainly composed of central tube 2, bubble cap 1, float valve 3 and valve seat 4;

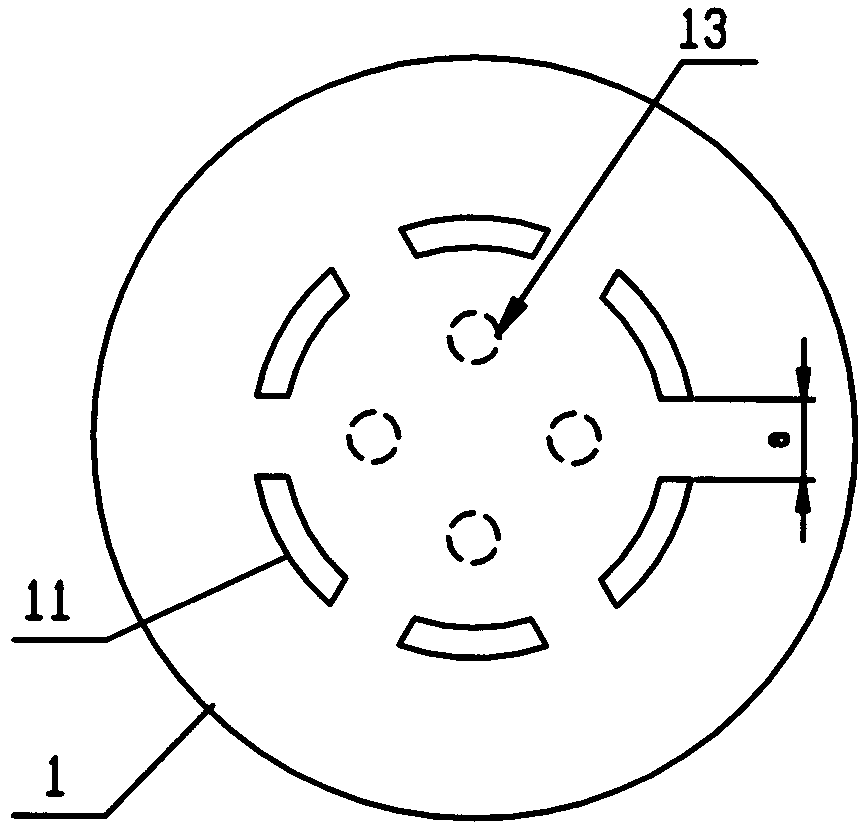

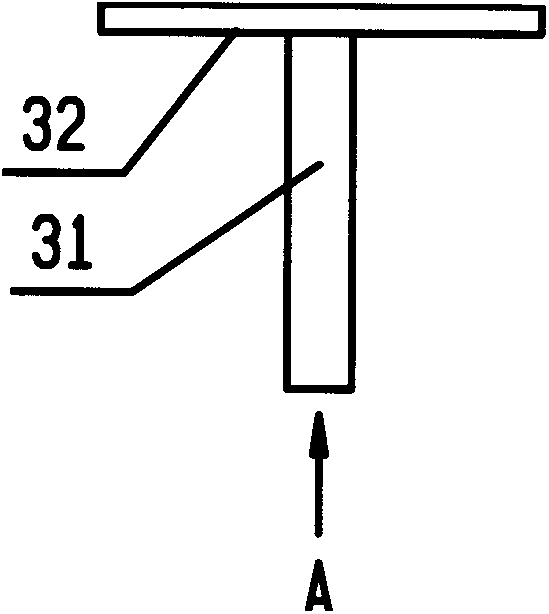

[0028] There is a material outlet on the tube wall at the upper end of the central tube 2, and a material inlet is opened at the lower section of the central tube. The bubble cap 1 is a barrel with one end open, which covers the upper end of the central tube 2. The bottom of the bubble cap and the barrel The wall junction is a rounded corner transition, and the barrel wall at the open end of the bubble cap is uniformly provided with a slit 12 that runs through the end along the axial direction of the bubble cap, and the inner wall of the bottom of the bubble cap bucket is provided with four evenly distributed cones 13 (such as figure 2As shown), the diameter of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com