Highly effective bionic surface sealing valve oil-well pump

A technology of bionic surface and sealing valve, which is applied in the field of mechanical lifting and oil mining mechanical lifting, can solve the problems of increasing liquid loss, reducing pump efficiency, and failing to meet the lifting needs of low-production wells, etc., to reduce fluid loss, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

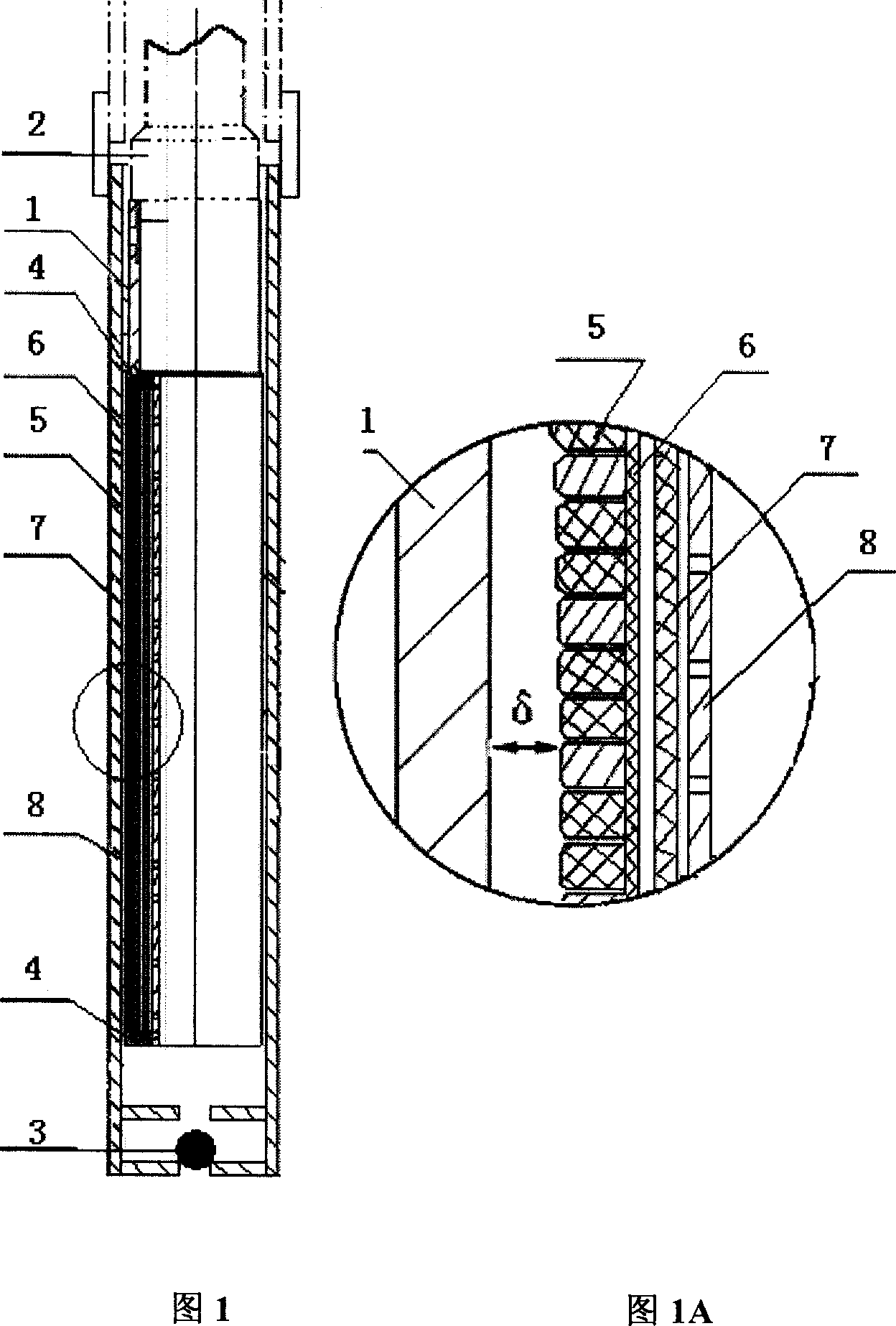

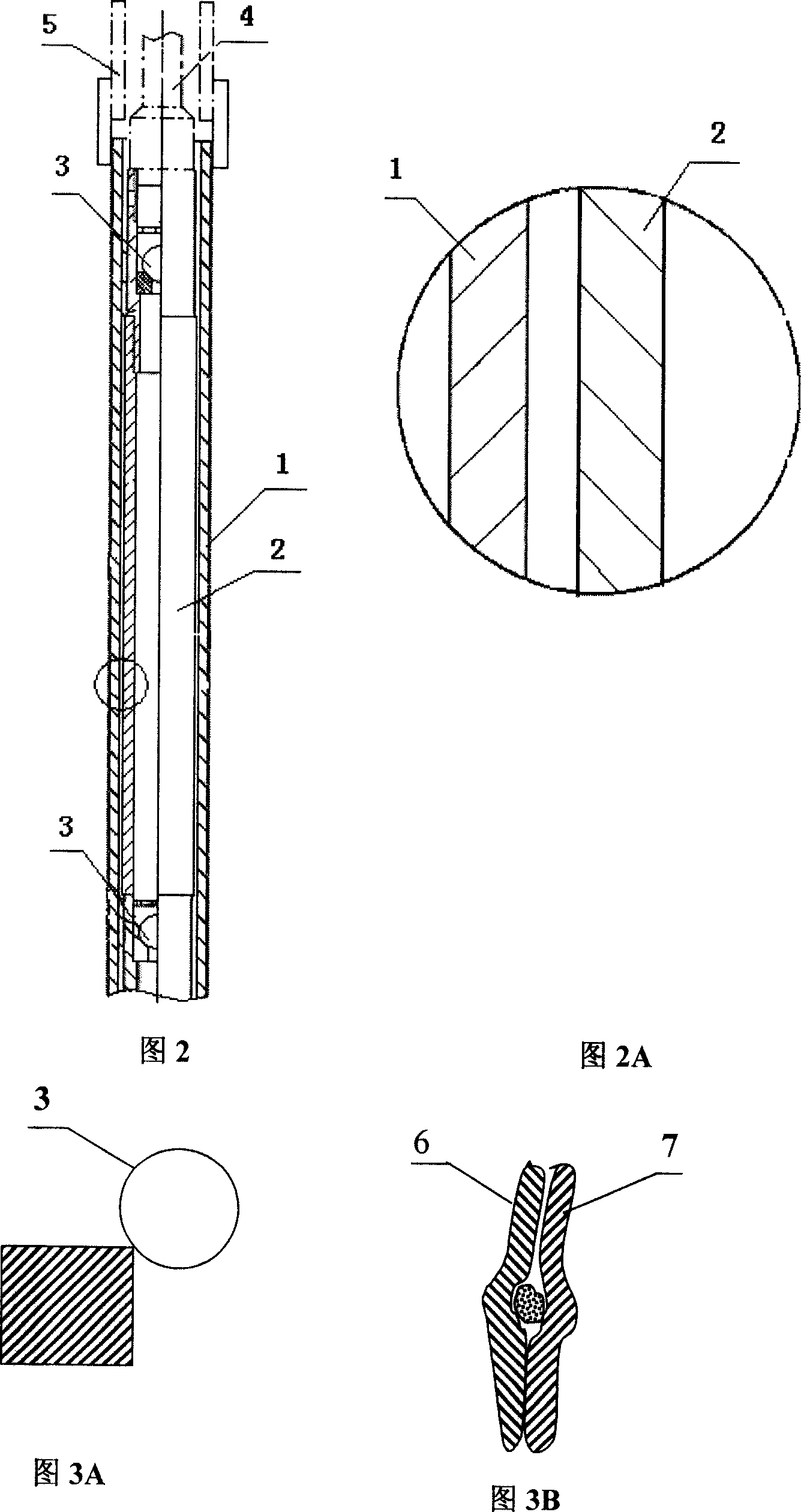

[0019] Referring to Fig. 1 and Fig. 1A, the high-efficiency bionic surface seal valve oil well pump of the present invention is composed of a pump barrel 1, a plunger 2, and a fixed valve 3, and the plunger 2 and the pump barrel 1 are in clearance fit; see Fig. 1A, the plunger 2 It is composed of a pressure-resistant and wear-resistant variable-diameter sealing ring 5, inner and outer elastic sealing bodies 6, 7 and a central rod screen tube 8; the outer circle of the central rod screen tube 8 is covered with two layers of elastic sealing bodies 6, 7, and the elastic sealing body Outside 6, cover a plurality of elastic rings 5 again, and press down with pressure cap 4 at both ends. Thus, the elastic ring 5 forms the outer surface of the plunger 2, and the gap between it and the pump barrel 1 forms a sealing surface, see Fig. 3B, the matching gap δ, the size of δ can be determined according to the concentration of the polymer contained in the pumped liquid, etc. factors to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com