Connecting rod drive type punching mechanism

A technology of connecting rod drive and drive end, applied in metal processing and other directions, can solve the problem of low punching efficiency, and achieve the effects of easy promotion and use, flexible action, low production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0018] Unless expressly stated otherwise, throughout the specification and claims, the term "comprising" or its conjugations such as "comprising" or "comprising" and the like will be understood to include the stated elements or components, and Other elements or other components are not excluded.

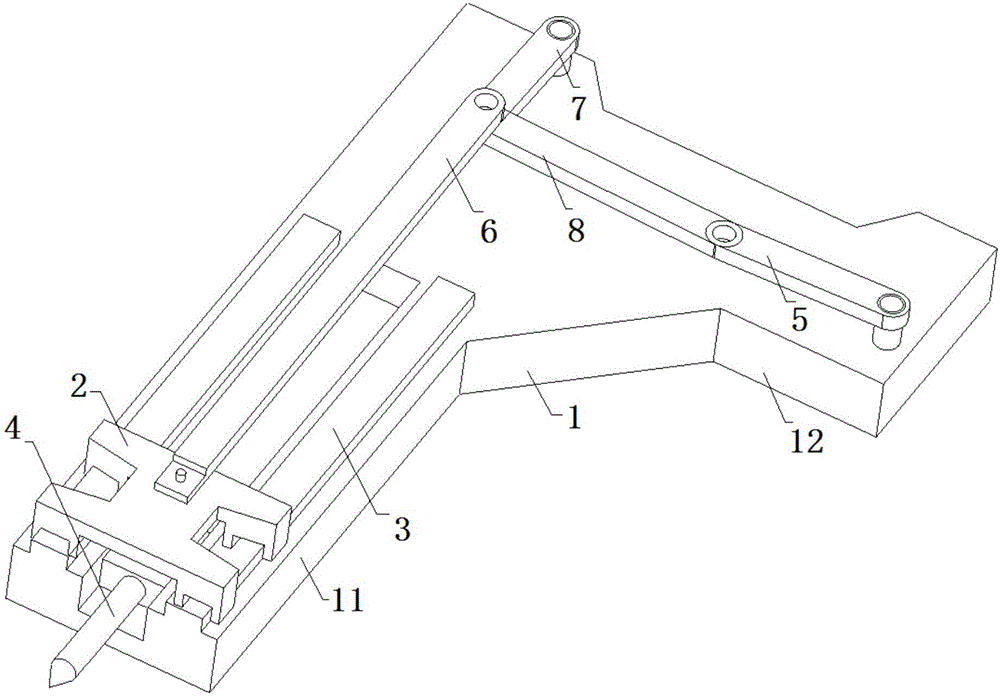

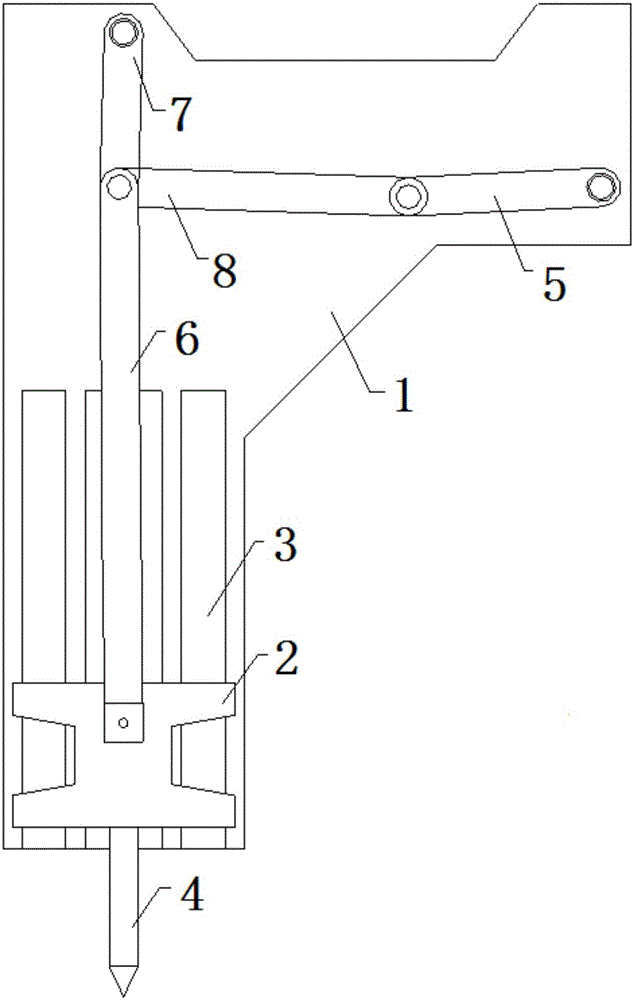

[0019] like Figure 1 to Figure 2 As shown, the connecting rod-driven punching mechanism according to the specific embodiment of the present invention includes: a main board 1, a slider 2, a punching needle 4, a sliding rod 6, an ejector rod 7, a pull rod 8 and a driving device; A driving end 12 and a punching end 11 are provided, and the driving end 12 is located to the right of the punching end 11; the punching needle 4 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com