A self-locking vehicle roof

A self-locking, vehicle roof technology, used in vehicle parts, roofs, transportation and packaging, etc., can solve the problems of easily damaged roof, large installation space, and large roof jitter, etc., to improve air convection and self-locking. Robust, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

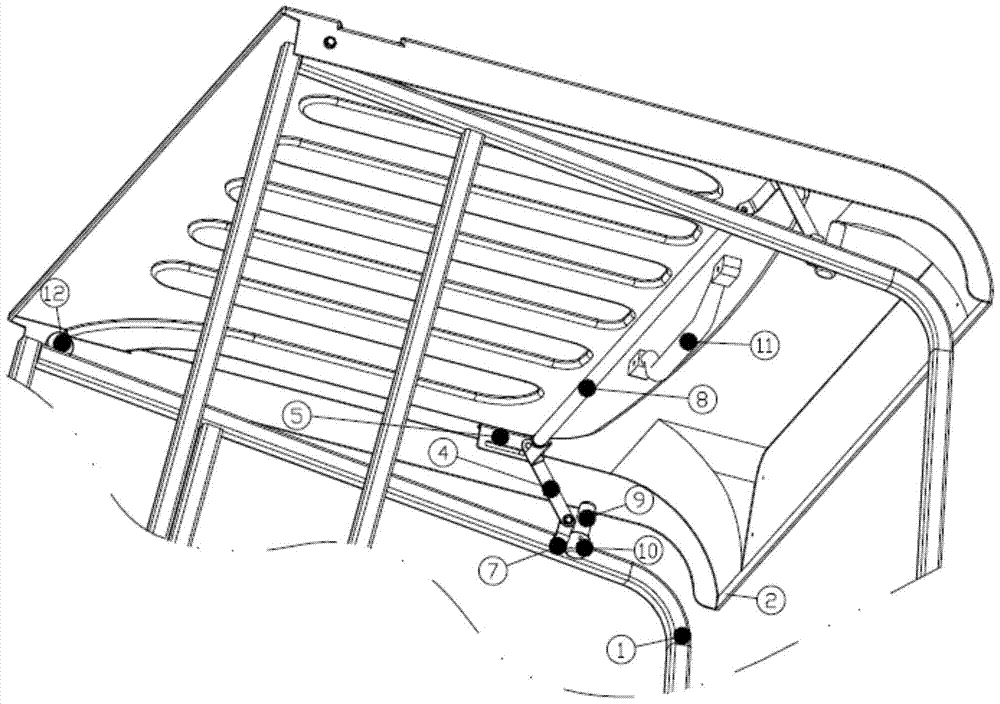

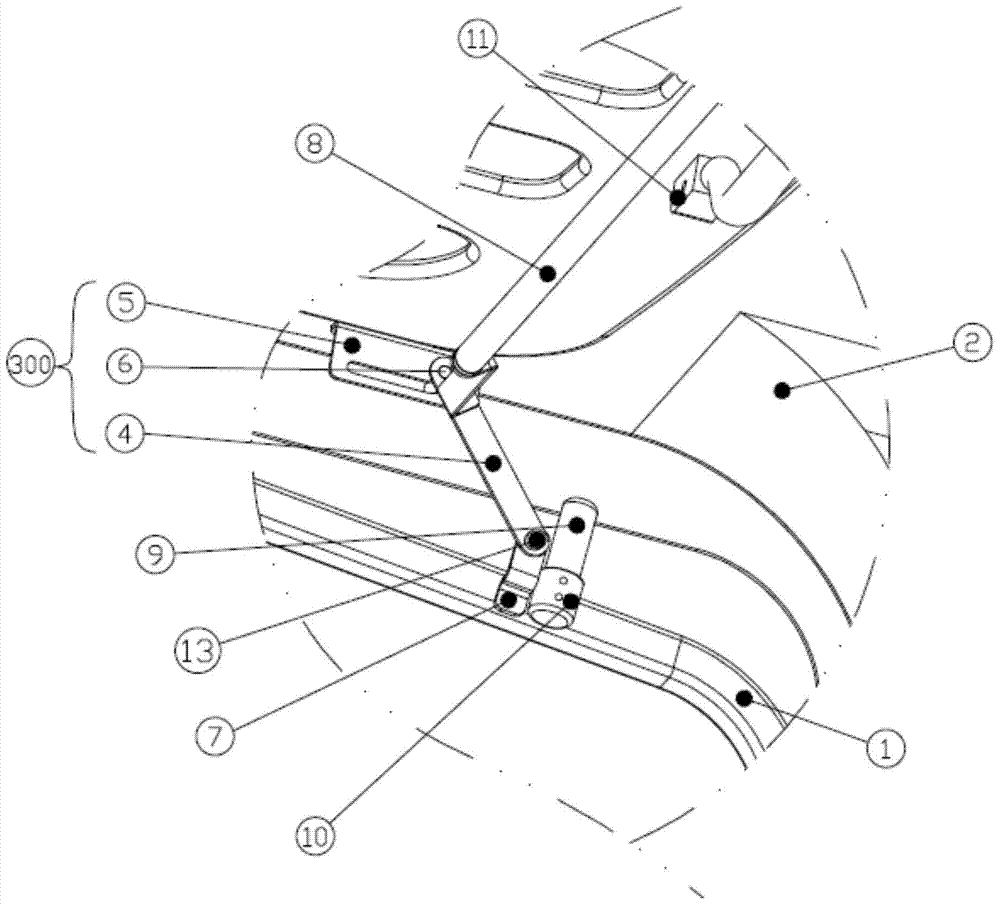

[0030] A self-locking vehicle roof, including a roof 2, the left end of the roof 2 is hinged on the vehicle frame assembly 1, and the right end is arranged on the vehicle frame assembly 1 in an openable and closable manner; it also includes a self-locking opening and closing Assembly 300, the self-locking opening and closing assembly 300 includes a push-pull guide rod 4, a guide plate 5 and a slider 6, the guide plate 5 is fixed on the top cover 2, and one end of the push-pull guide rod 4 is hinged on the vehicle On the frame assembly 1, the slider 6 is fixed on the other end of the push-pull guide rod 4, and the slider 6 is slidably arranged on the guide plate 5;

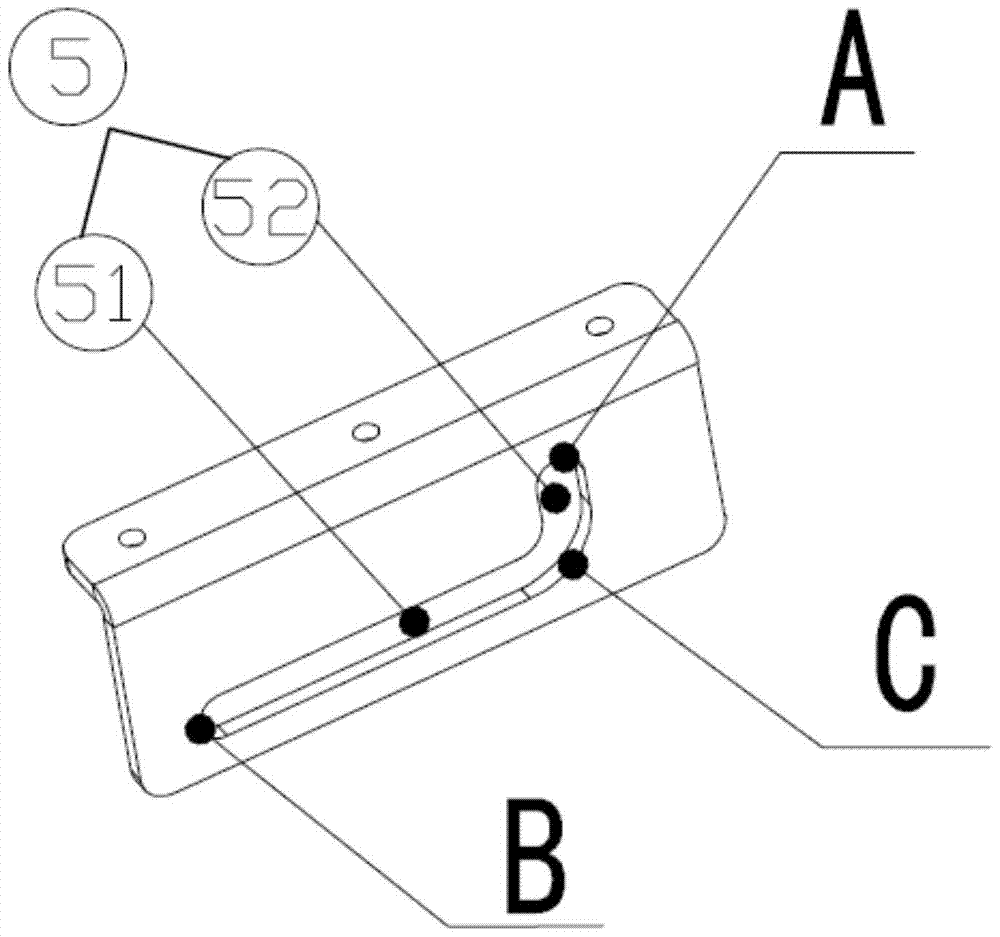

[0031] The guide plate 5 is provided with a sliding part 51 and a self-locking part 52, the sliding part 51 extends in a direction para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com