Hanging mechanism used between ship and highline cable

A technology for overhead cables and ships, which is applied to ship accessories, transportation and packaging, ships, etc. It can solve the problems of uncoupling of elevated cables and the inability to achieve stable and reliable connection between the hook mechanism and the elevated cables, and achieve good connection effects and realize automatic separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

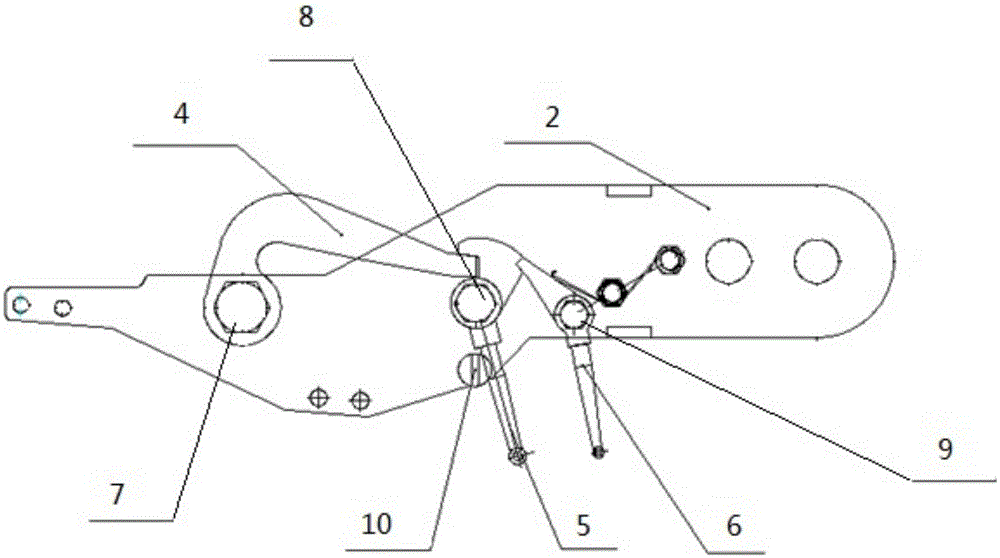

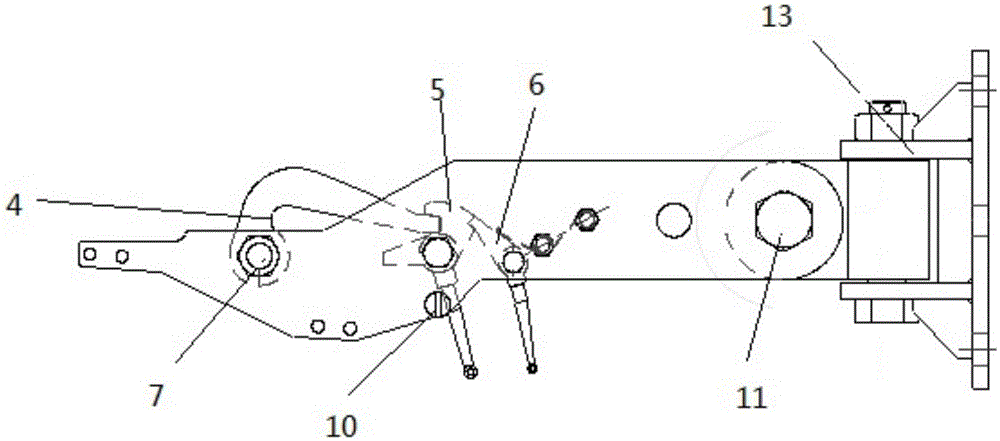

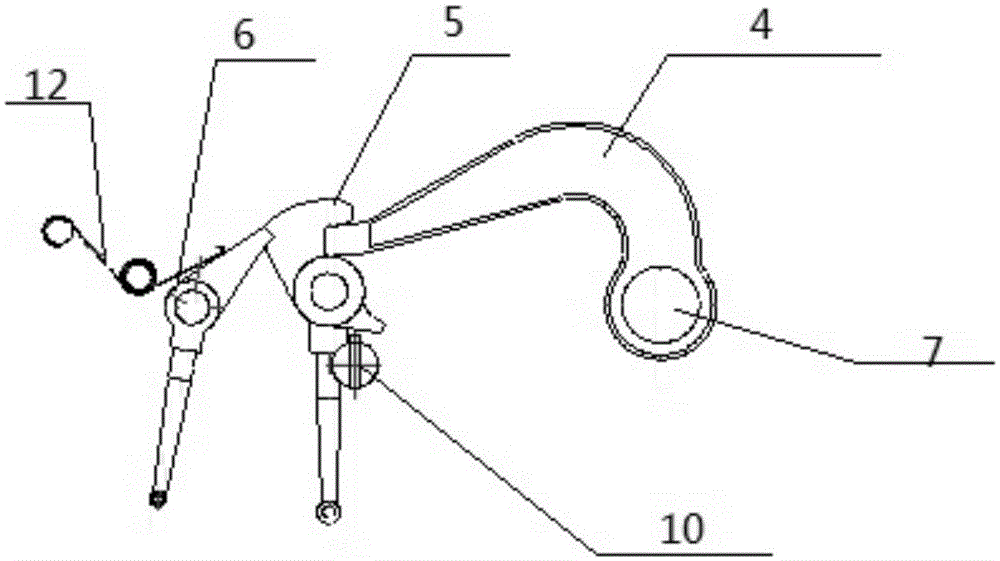

[0022] Such as figure 1 As shown, the hooking mechanism in this embodiment includes: an emergency release mechanism, a connecting side plate 2, and a base 3. The emergency release mechanism includes an overhead cable hook 4, a live card 5, a stop card 6, and several pin shafts 7- 9. Safety card pin 10.

[0023] As shown in the figure, the connecting side plate 2 is strip-shaped. In this embodiment, the connecting side plate includes a left part and a right part, the left part is slightly lower than the right part, and there are several through holes on the connecting side plate 2 .

[0024] The overhead cable hook 4 is a curved hook, and one end (fixed end) of it is rotatably installed on the left part of the connecting side plate in the figure by a pin 7, and is positioned at the side of the connecting side plate facing the paper. Pin shaft 7 is matched with the through hole connecting the left side of the side plate. And the free end (the right end in the figure) of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com