Transport device capable of carrying goods automatically

A technology for transportation devices and goods, applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve the problems of increasing labor intensity of workers, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

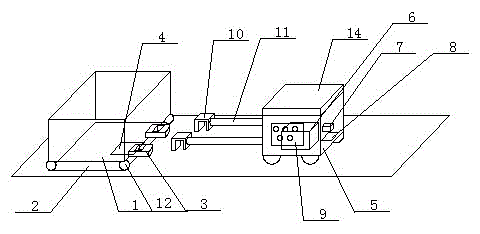

[0014] Below in conjunction with accompanying drawing, the present invention will be further described.

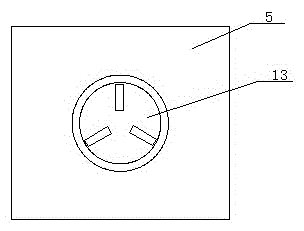

[0015] see figure 1 and figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes a loading bucket 1, a floor scale 2, a pull button 3, an alarm 4, a motion mechanism 5, a power supply 6, a controller 7, a memory chip 8, a control panel 9, Manipulator 10, hydraulic rod 11, roller 12, universal wheel 13; said floor scale 2 is arranged on the ground, and a loading bucket 1 is movable on the floor scale 2, and a pull button 3 is provided on one side of the loading bucket 1; An alarm 4 is provided on the weighbridge 2; a power supply 6 and a controller 7 are arranged inside the moving mechanism 5, a memory chip 8 is arranged under the controller 7, and a control panel 9 is arranged outside the moving mechanism 5 One side of the movement mechanism 5 is screwed with a hydraulic rod 11, and one end of the hydraulic rod 11 is screwed with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com