Conveyer belt deviation detecting method based on image identification

A technology of image recognition and detection method, which can be applied to conveyor objects, conveyor control devices, transportation and packaging, etc., and can solve problems such as poor real-time performance and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

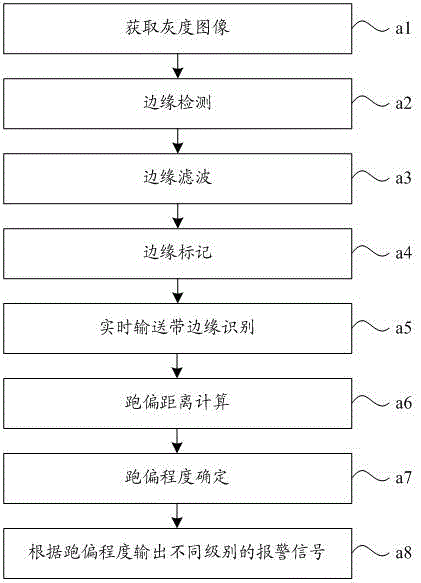

[0039] See figure 1 , which is a flow chart of an embodiment of the image recognition-based conveyor belt deviation detection method of the present invention.

[0040] The core technical idea of the conveyor belt deviation detection method based on image recognition described in this embodiment is to use the edge detector to directly detect the edge of the object in the real-time image, and then based on the known conveyor belt left deviation when the conveyor belt is not deviation , right reference edge to match and identify the detected edges, so as to identify the left and right real-time edges of the conveyor belt in the real-time image, and then process according to the positions of the conveyor belt reference edge and real-time edge, and then detect whether the current conveyor belt is Off track. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com