Film guide for photoelectrically controlled cutter

A photoelectric control and guiding device technology, which is applied in transportation and packaging, winding strips, and thin material processing, etc., can solve problems such as film wrinkles, affecting film feeding, and affecting the work of guide rollers, so as to improve friction, The effect of preventing shrinkage and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

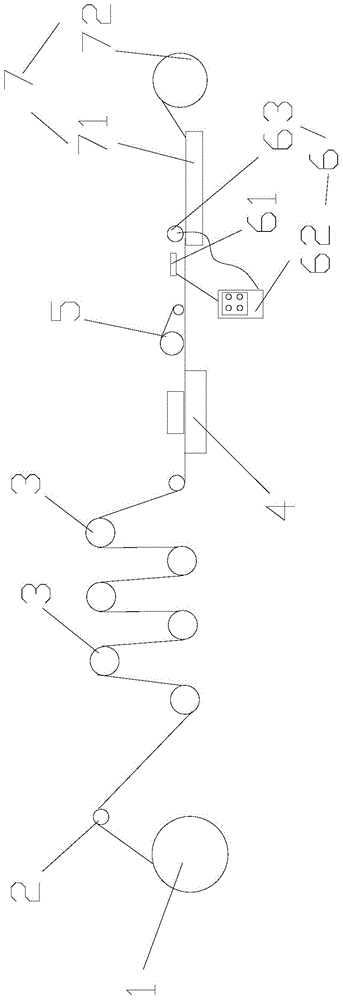

[0020] Such as Figure 1-5 As shown, this embodiment discloses a photoelectric control cutting machine, including a feed roller 1 , a tension roller 2 , a guide roller 3 , a lamination mechanism 4 , a guide device 5 , and a photoelectric cutting device 6 .

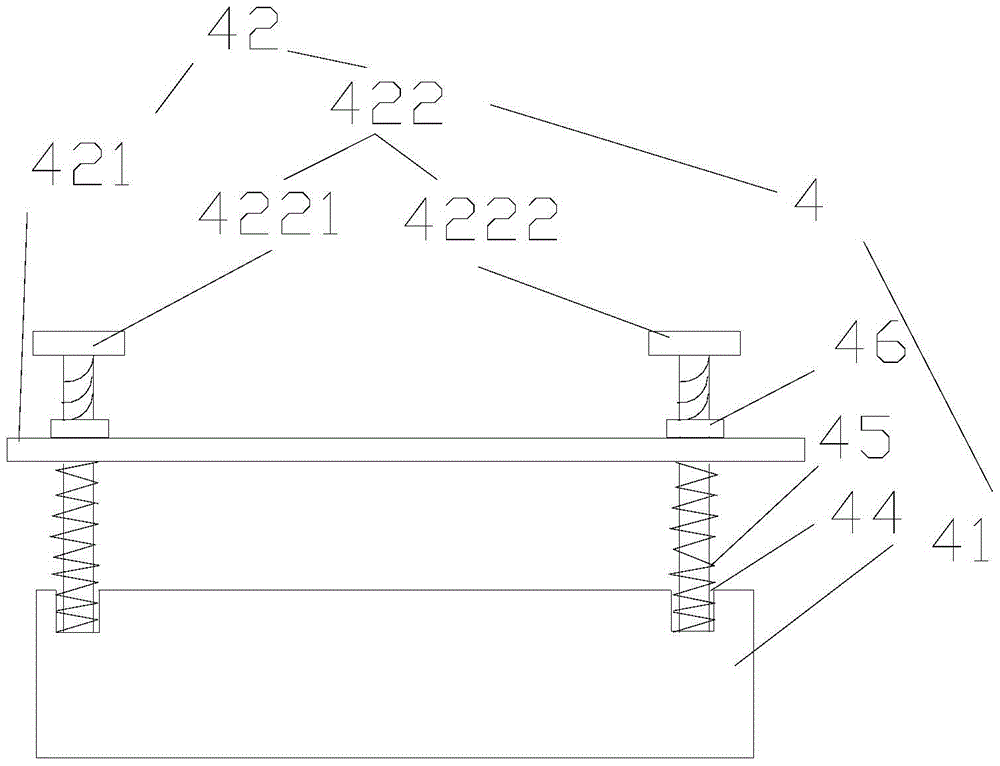

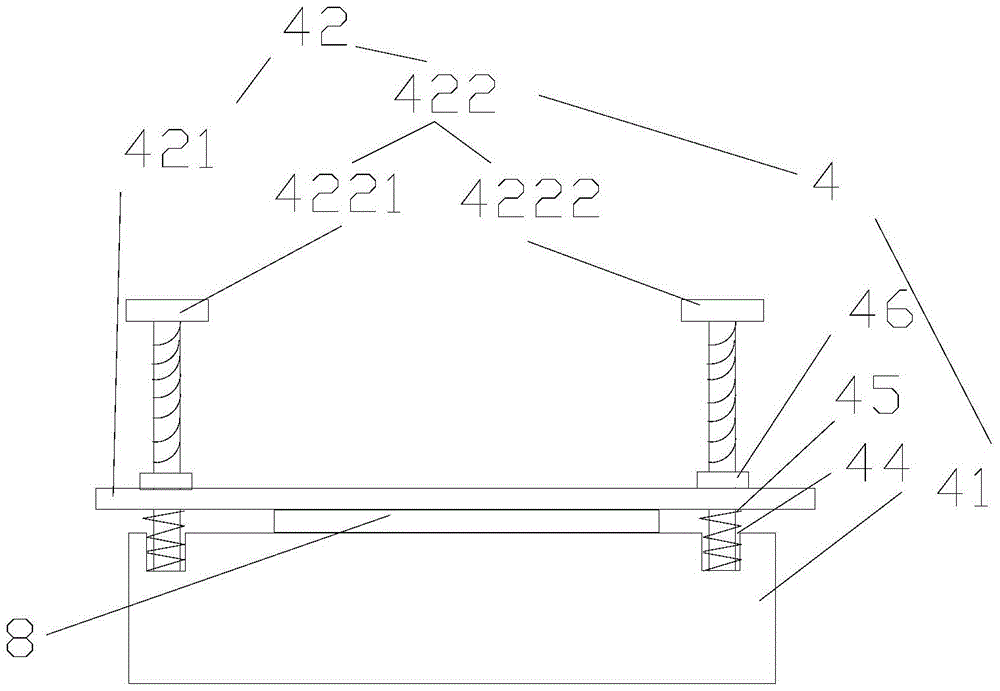

[0021] The feeding roller 1, the tension roller 2, the guide roller 3, the laminating mechanism 4, the guiding mechanism 5, and the photoelectric cutting device 6 are arranged sequentially from front to back according to the technological process; the laminating mechanism 4 includes an upper support plate 41 and a pressing plate A film device 42 , the lamination device 42 is located above the upper support plate 41 and can move up and down relative to the upper support plate 41 ; the photoelectric cutting device 6 is used for cutting the film 8 to length.

[0022] The laminating device 42 includes a lower platen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com