Leg displacement method

A technology of pile leg and fixed position, which is applied in the field of displacement of pile leg assembly, can solve problems such as time-consuming and labor-intensive, and achieve the effect of saving loading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention will be clearly and completely described through the preferred embodiments of the present invention in conjunction with the accompanying drawings.

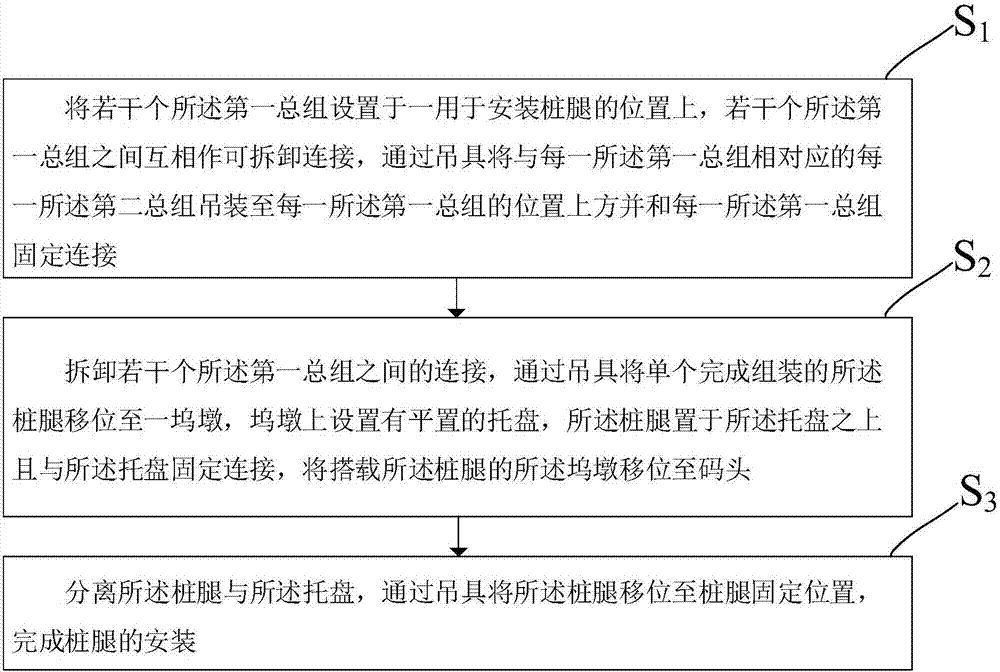

[0032] Such as figure 1 As shown, a leg displacement method involved in this embodiment includes the following steps:

[0033] S 1 1. Fixedly connecting the first overall group and the second overall group to complete the assembly of the pile legs.

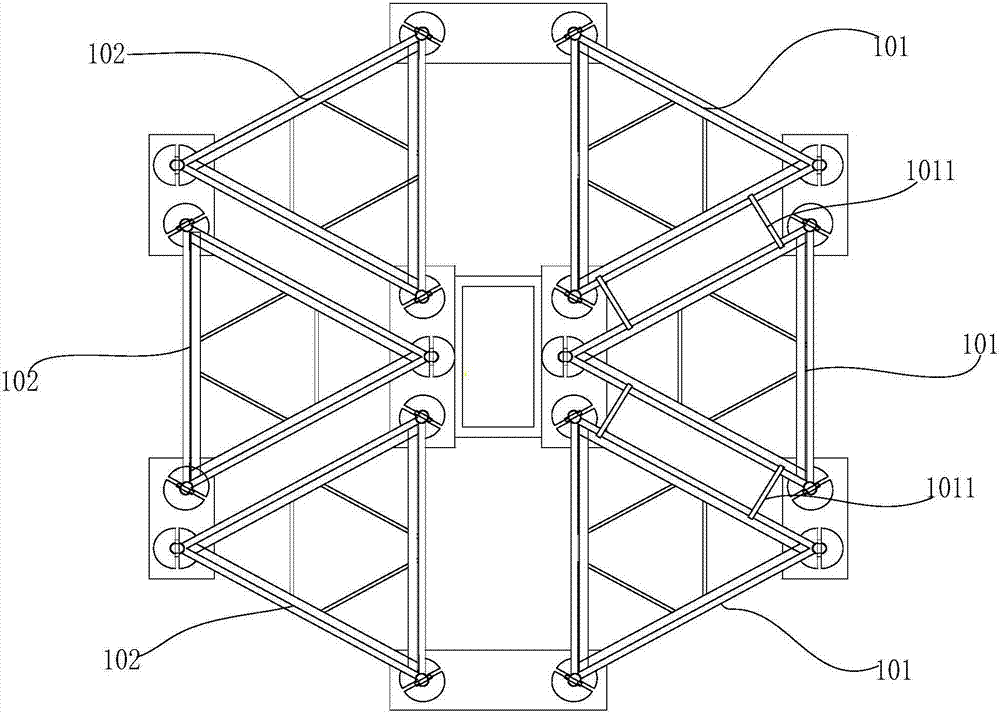

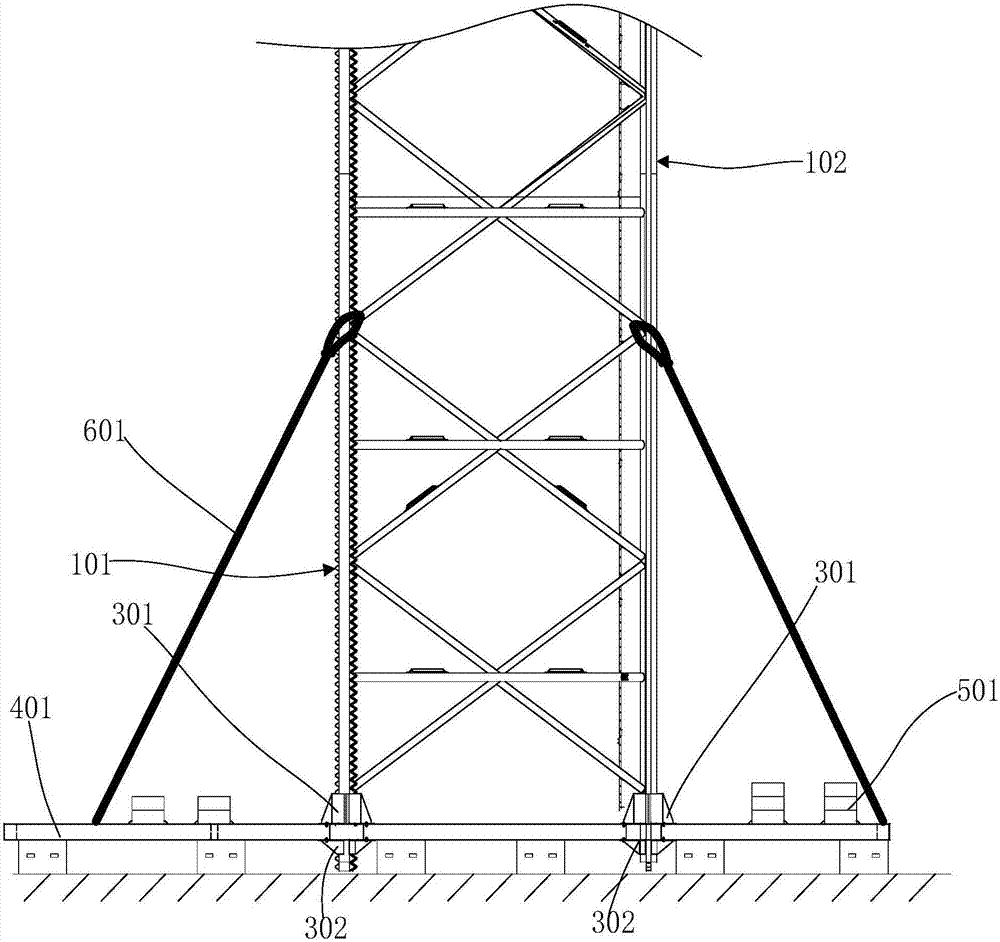

[0034] Such as figure 2 As shown, in this embodiment, since the total number of legs is 3, the first group 101 and the second group 102 that make up the legs are 3 respectively. The three first general groups 101 are arranged at predetermined fixed positions, and the tops of the three first general groups 101 are provided with tie rods 1011 , and are detachably connected through the tie rods 1011 . The three first general groups 101 form a whole, which enhances its torsion resistance.

[0035] Afterwards, the three second general groups 102 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap