A method and connection structure for ensuring the normal operation of a flat fixed-wheel steel gate

A technology for normal operation and gates, which is used in coastline protection, water conservancy engineering, marine engineering and other directions to achieve the effects of improving reliability, preventing damage and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

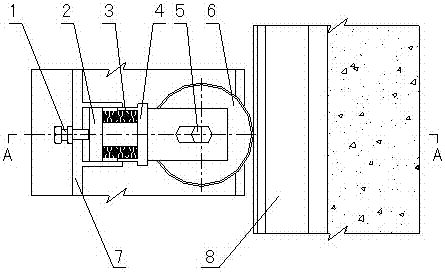

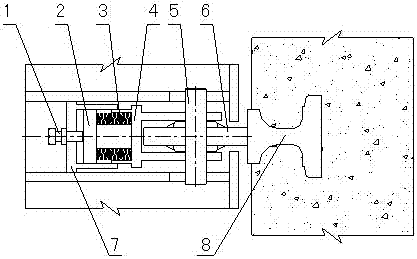

[0019] This example figure 1 and figure 2 As shown, the adjusting screw 1 and the thrust block 2 in the figure are installed in the chute of the door body frame 7 to provide pre-tightening thrust for the wheels 6; the stacked spring group 3 is installed in the chute of the door body frame 7, and the stacked spring group 3. The right end bears on the thrust block 2, and the left end of the stacked spring group 3 bears on the movable push frame 4, which is used to adjust the expansion and contraction of the wheels 6; the movable push frame 4 is slidingly connected with the chute of the door frame 7, and the right end of the movable push frame 4 is The fork-shaped structure is connected with the wheel 6 through the rotation of the wheel shaft 5, and the left end of the movable push frame 4 bears on the stack spring group 3, and transmits the pressure and stretching amount from the stack spring group 3 to the wheel 6; the wheel shaft 5 and the wheel 6 and the movable push frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com