Anchor cable outer anchor head steel strand protective device and installation method thereof

A technology of protection device and steel strand, which is applied in the installation of bolts, earthwork drilling, sheet pile walls, etc., can solve the problem of reducing the service life of the anchor cable, intrusion, and failing to meet the waterproof and anti-corrosion protection requirements of the outer anchor head steel strand. and other problems to achieve the effect of improving service life and good working characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but these embodiments should not be construed as limiting the present invention.

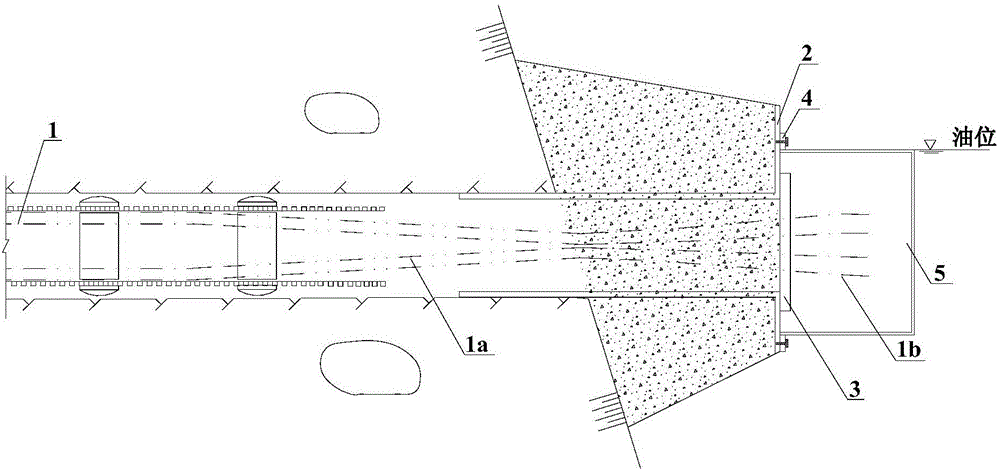

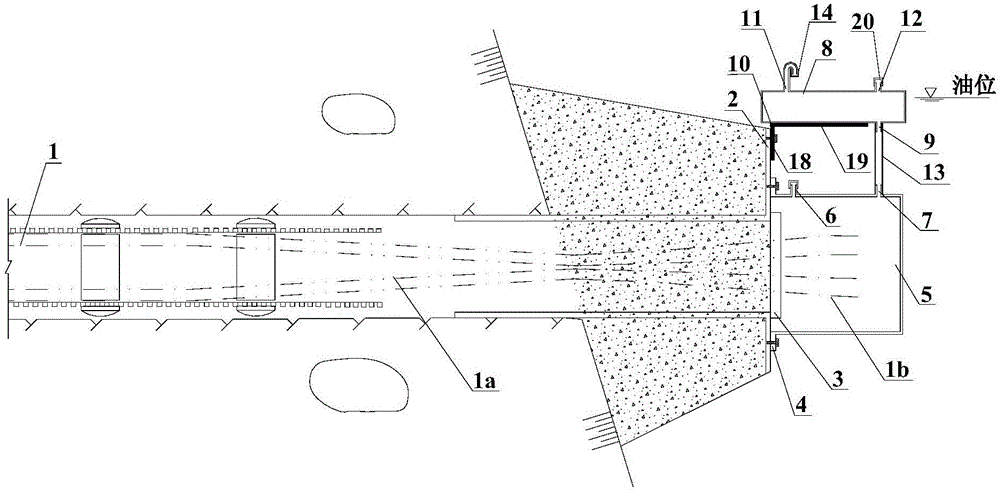

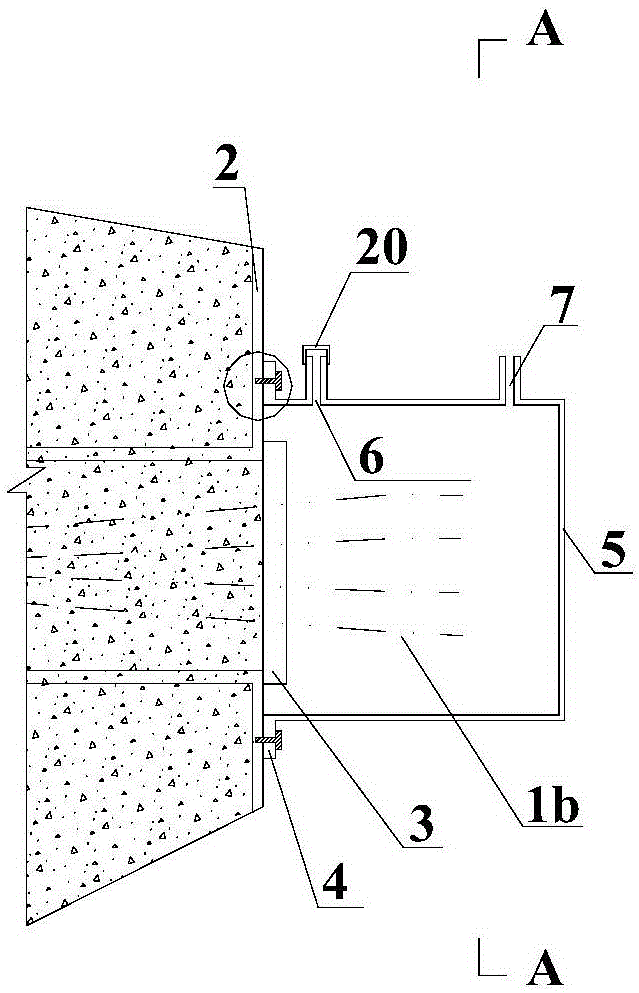

[0045] Figure 2-10 The steel strand protection device for the outer anchor head of the anchor cable includes a steel strand 1, a steel backing plate 2 for the tensioned steel strand and an anchor 3 for the tensioned steel strand. The steel strand includes a The inner steel strand 1a inside and the outer anchor head steel strand 1b protruding from the outside of the anchorage 3, the outer anchor head steel strand 1b is surrounded by a cylindrical protective cover 5 with a flange 4 at the end, and the flange 4 Connected to the steel backing plate 2 by bolts, the top wall of the protective cover 5 is provided with a first exhaust pipe 6 and a first oil inlet 7, the upper part of the protective cover 5 is provided with a supply oil tank 8, and the bottom wal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap