Insert bolt using core bushing and manufacturing method of core bushing

A bushing and bolt technology, applied in the direction of screws, connecting components, threaded fasteners, etc., can solve problems such as difficult bolt holes for operators, delay in assembly time, bolt wear, etc., to achieve accuracy and stability, The effect of maintaining binding force and good binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

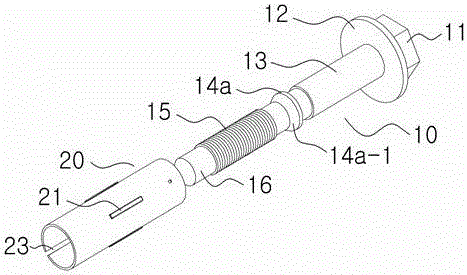

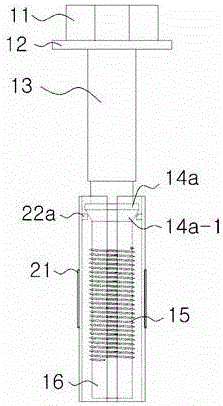

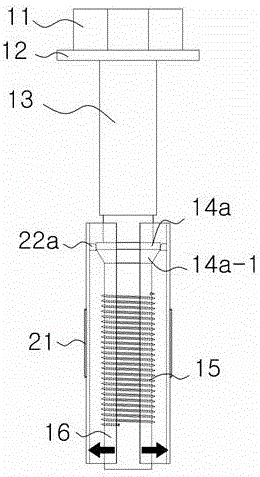

[0033] Next, the present invention will be described in detail with reference to the drawings. Such as figure 1 As shown, the present invention consists of a bolt 10 and a bushing 20 surrounding the bolt 10. The bolt 10 is composed of a polygonal head 11, a circular washer 12 located on the underside of the head 11, an upper body part 13 and a lower body part 16 connected from the washer 12 to the bottom. A blocking portion 14a having a radius larger than that of the upper body portion 13 and the lower body portion 16 is formed between the upper body portion 13 and the lower body portion 16. The upper side of the blocking portion 14a is perpendicular to the bolt 10, and the lower side has a slope surface 14a-1 inclined downward toward the central axis of the bolt 10. Threads 15 are formed on the lower body portion 16 and are combined with nuts embedded in the base material 30 . The screw thread 15 is formed at the central portion of the lower body portion 16 and is not conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com