Patents

Literature

38results about How to "Mentioned accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

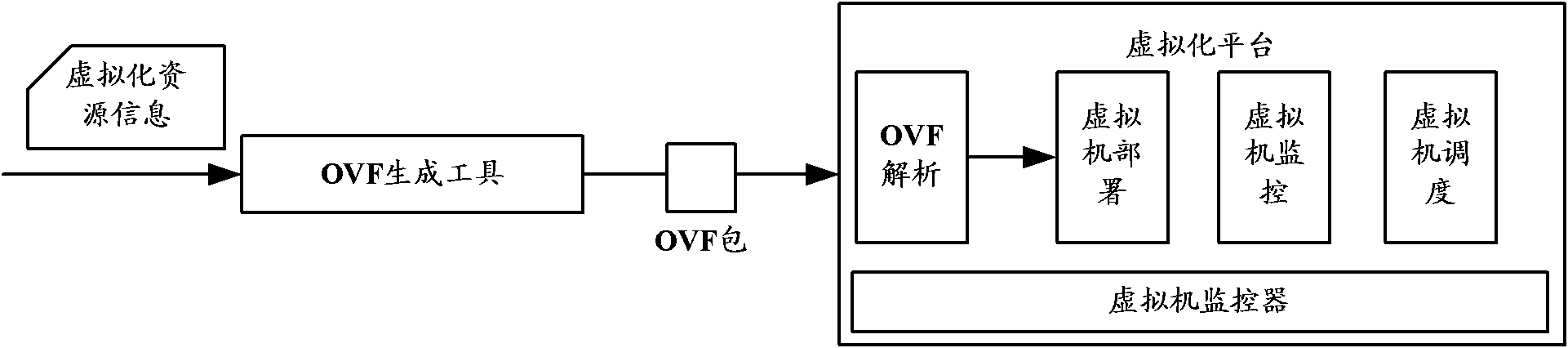

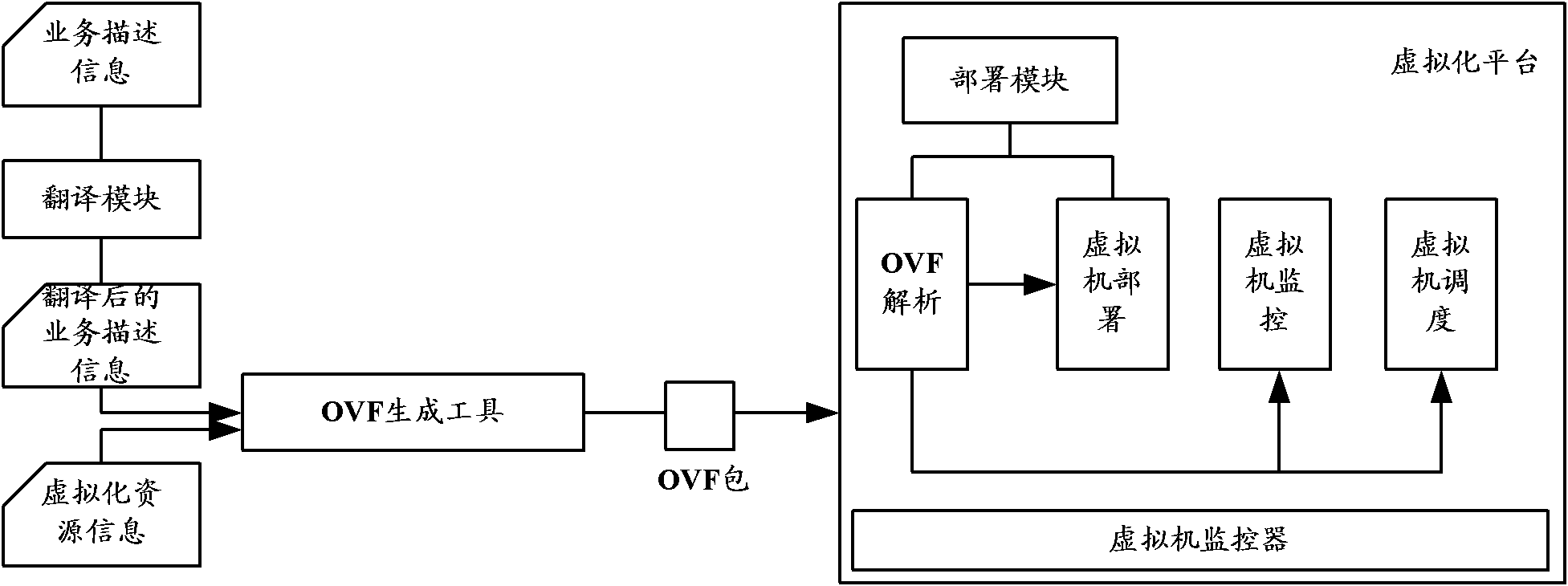

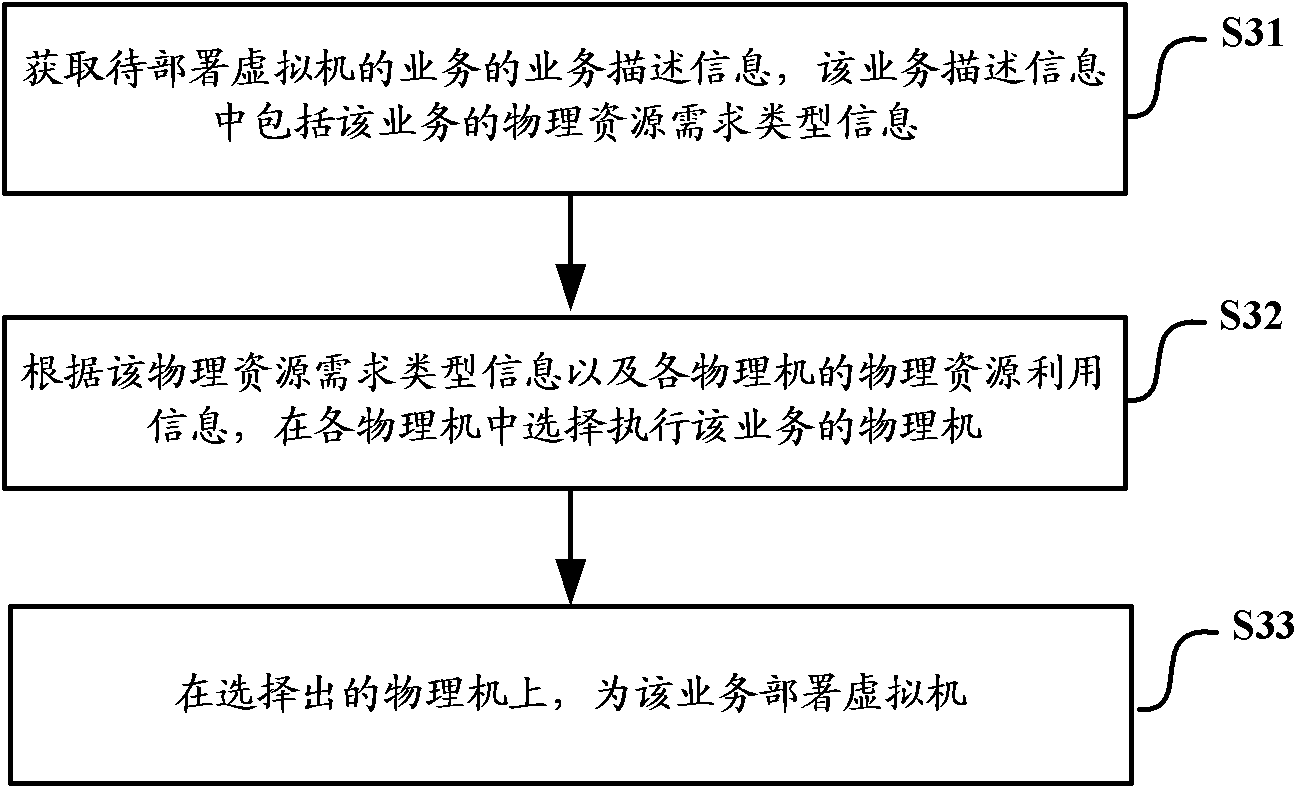

Virtual machine deployment method, device and system

ActiveCN102646052AMentioned efficiencyMentioned accuracySoftware simulation/interpretation/emulationResource utilizationVirtual machine

The invention discloses a virtual machine deployment method, a virtual machine deployment device and a virtual machine deployment system which are used for improving the efficiency and the accuracy of virtual machine deployment, wherein the virtual machine deployment method comprises the following steps of: acquiring business description information of business of a virtual machine to be deployed, wherein the business description information comprises physical resource demand type information of the business; selecting a physical machine for executing the business from each physical machine according to the physical resource demand type information and physical resource utilization information of each physical machine; and deploying the virtual machine on the selected physical machine for the business.

Owner:CHINA MOBILE COMM GRP CO LTD

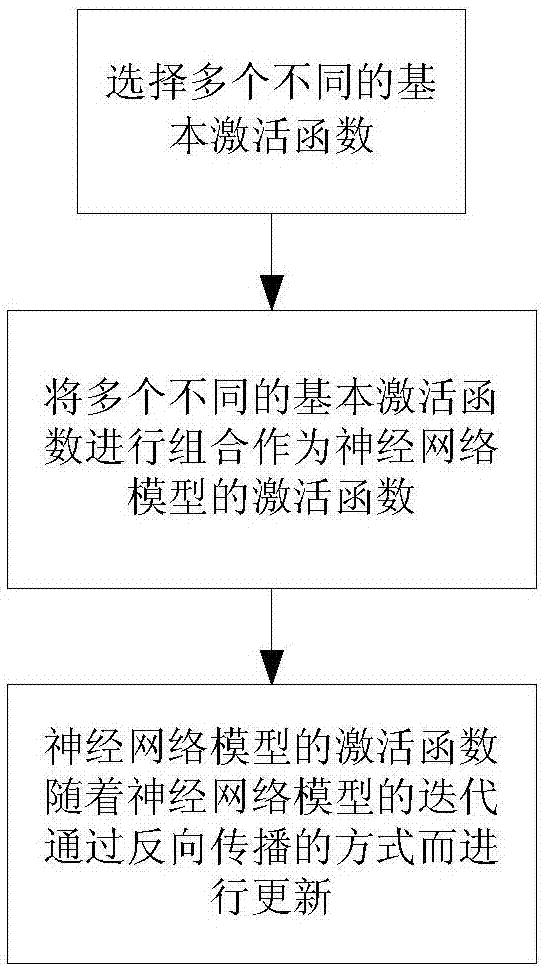

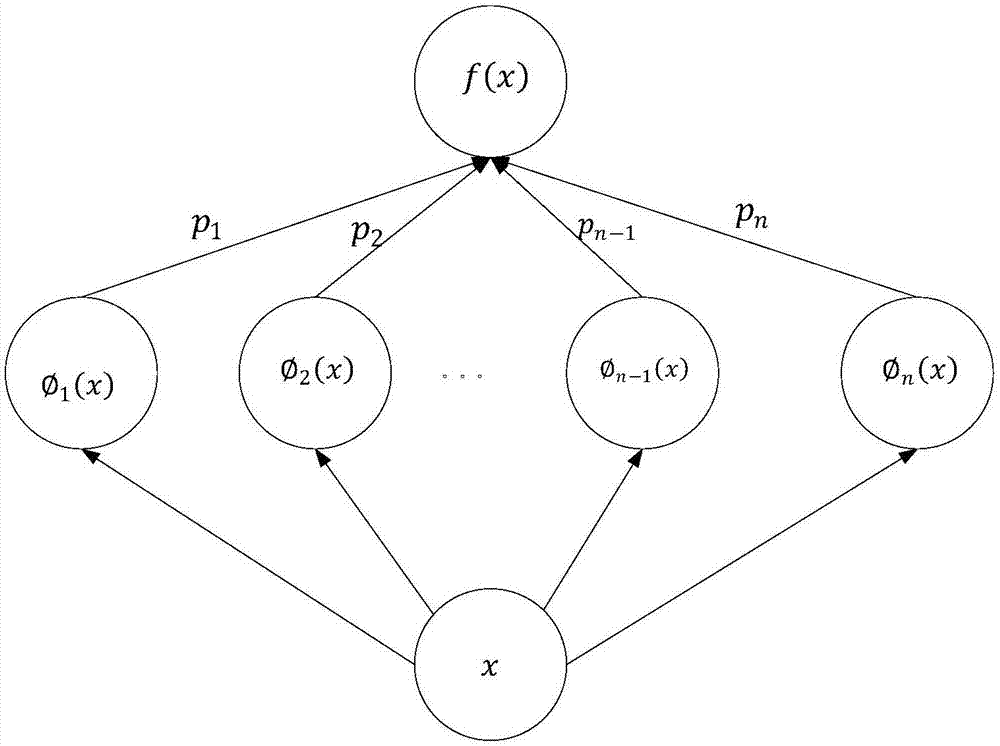

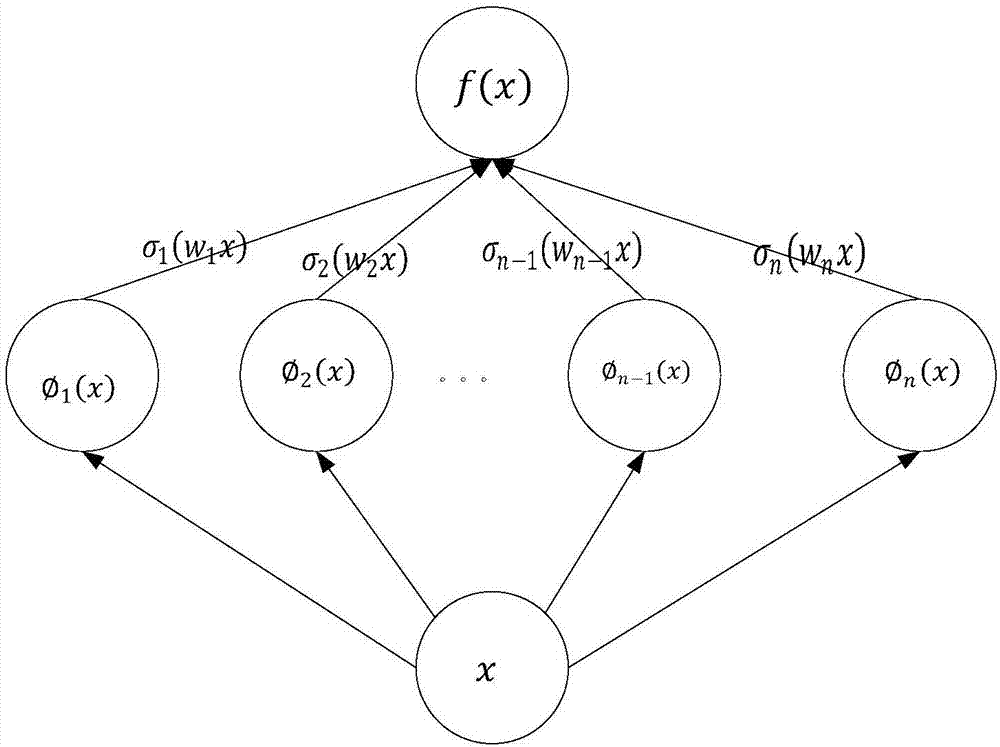

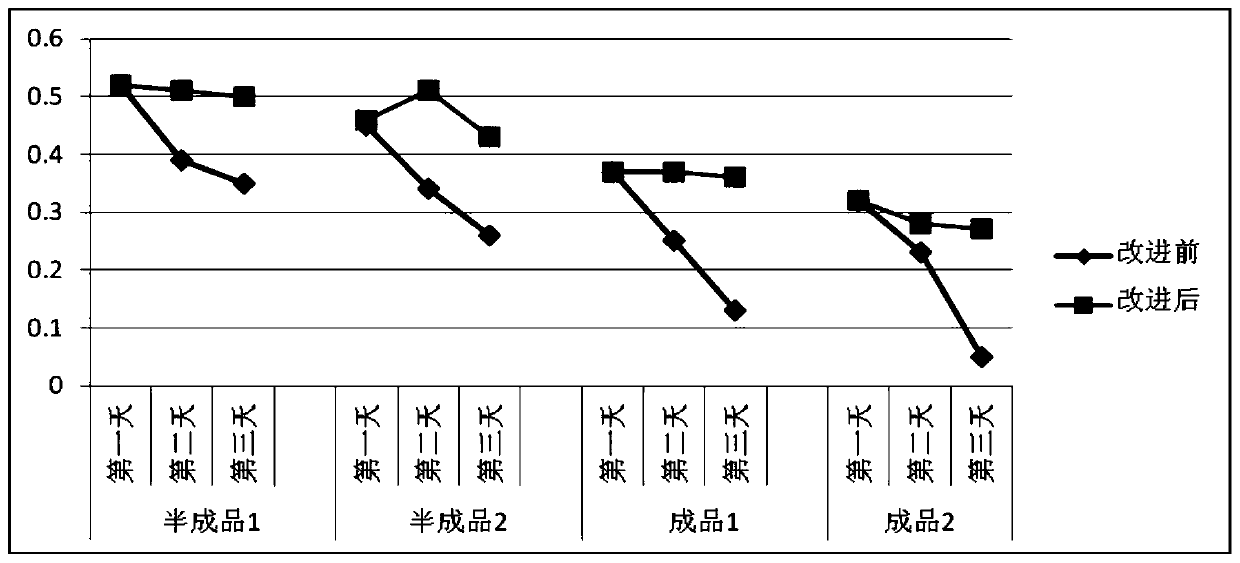

Activation function generation method of neural network model

InactiveCN107122825AImproved ability to learn non-linear changesMentioned accuracyNeural architecturesMachine learningNetwork model

The present invention discloses an activation function generation method of a neural network model. The method includes the following steps that: S1, a plurality of different basic activation functions are selected; S2, the different basic activation functions selected in the S1 are combined so as to form the activation function of the neural network model; and S3, the activation function of the neural network model is updated with the iteration of the neural network model through a back propagation means. With the activation function generated by using the method of the invention can improve the nonlinear change learning capability of the neural network model, and the neural network model can respond differently to different input in a test stage, and a defect that a neural network uses a single activation function can be eliminated.

Owner:SOUTH CHINA UNIV OF TECH

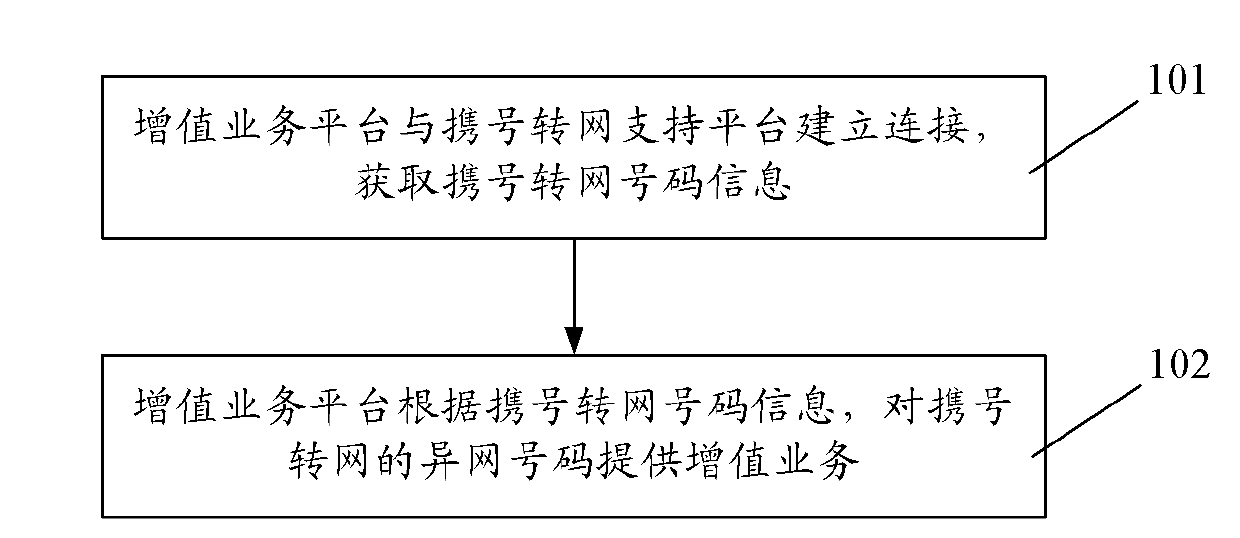

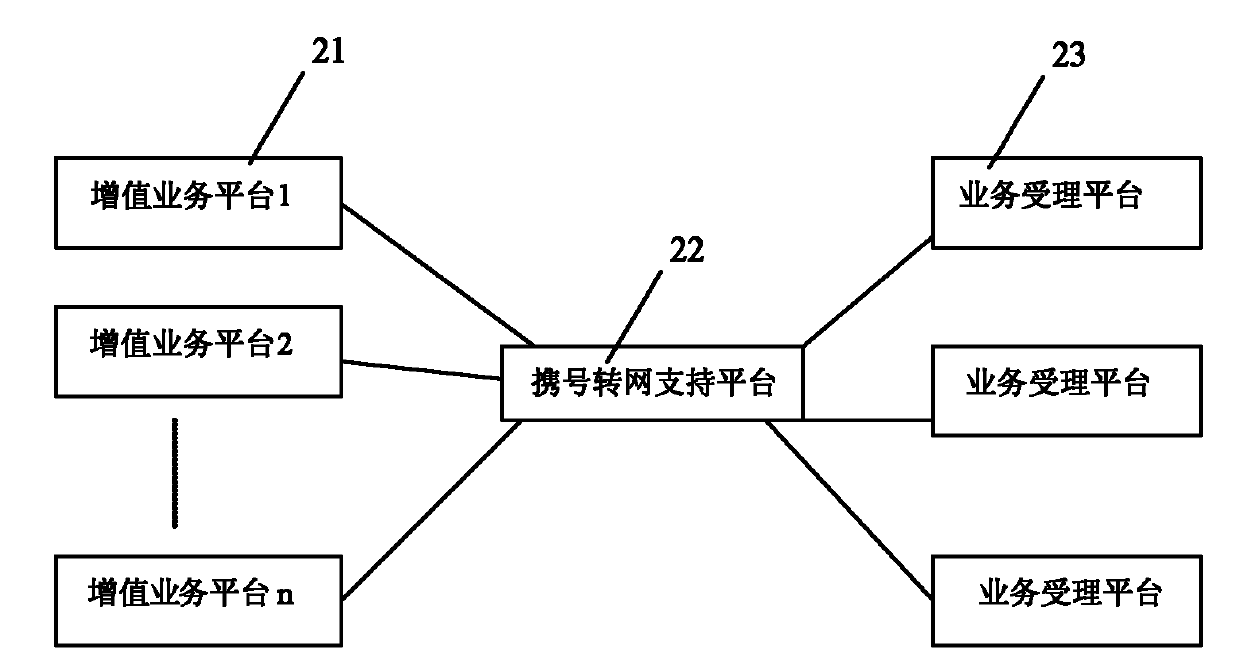

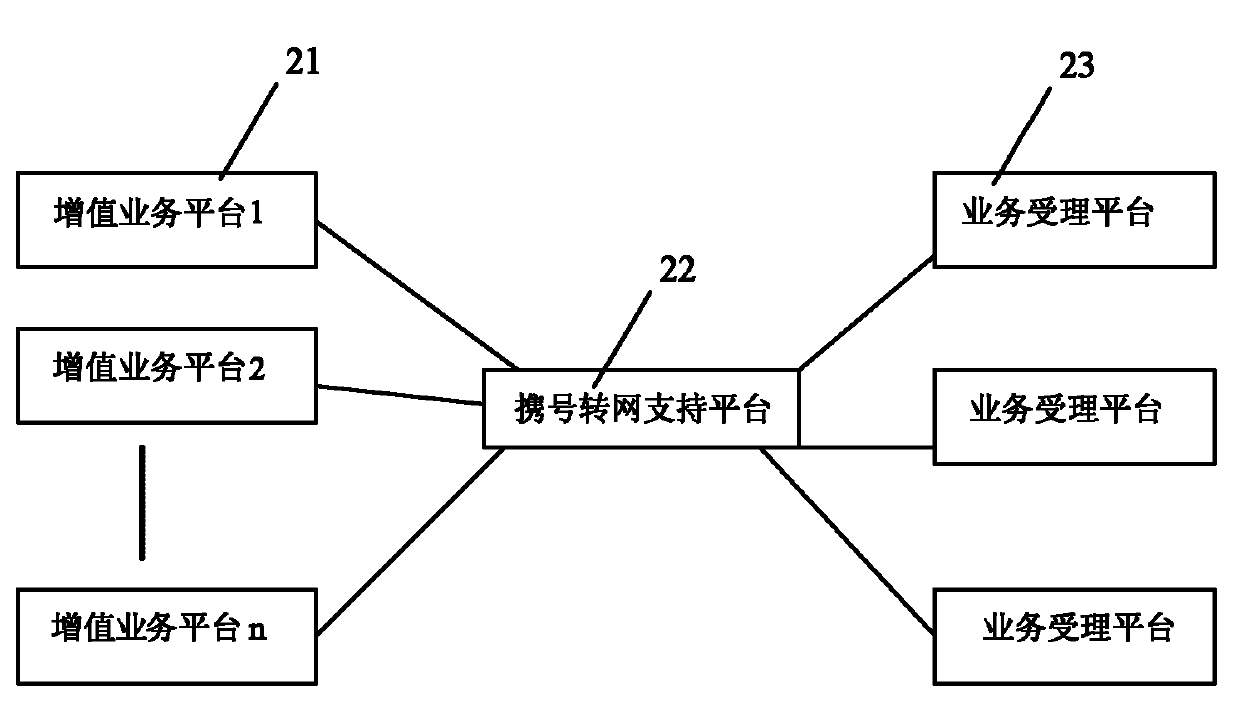

Method and system for realizing mobile number portability of value-added service

InactiveCN102170635AMentioned accuracyNetwork data managementMobile number portabilityValue-added service

The invention provides a method and system for realizing mobile number portability of value-added service. The system comprises a value-added service platform and a mobile number portability support platform, wherein the mobile number portability support platform is used for sending the number information of mobile number portability to the value-added service platform; and the value-added service platform is used for establishing a connection with the mobile number portability support platform, obtaining the number information of mobile number portability, and providing the value-added service to the isomerous-network number of mobile number portability according to the number information of mobile number portability, wherein the number information of mobile number portability comprises the isomerous-network number range information or isomerous-network number information. The method and system for realizing mobile number portability of value-added service provided by the invention can be used for establishing the connection between the value-added service platform and the mobile number portability support platform, automatically obtaining the number information of mobile number portability for configuration, and greatly improving the configuration efficiency and accuracy compared with the manual configuration mode in the prior art.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

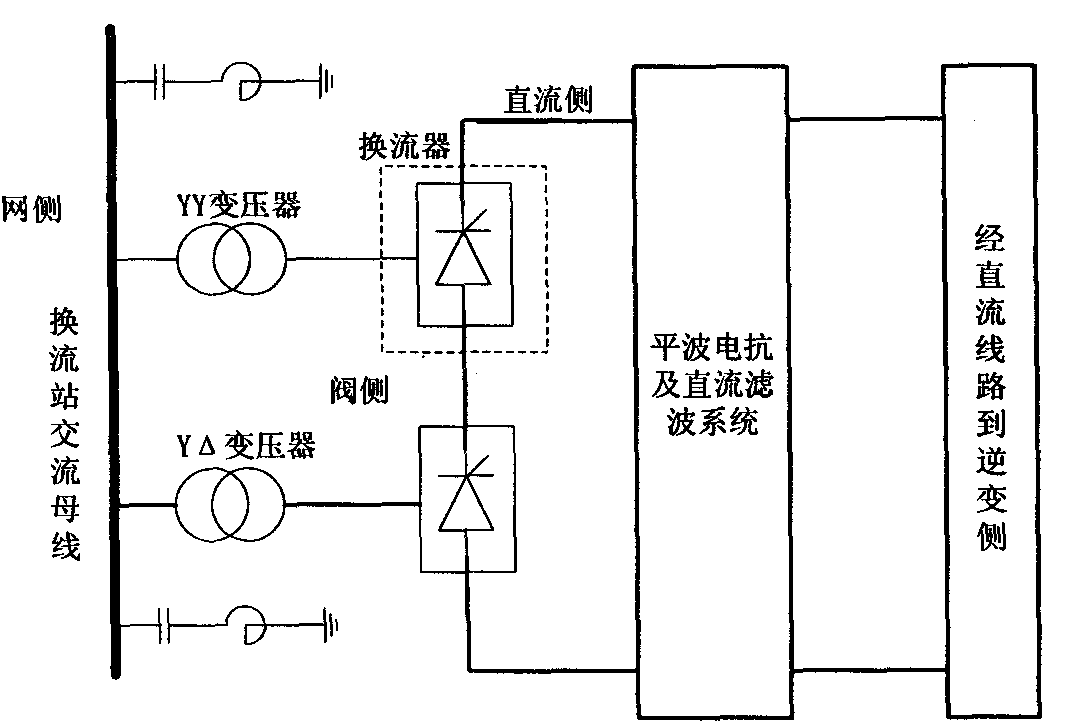

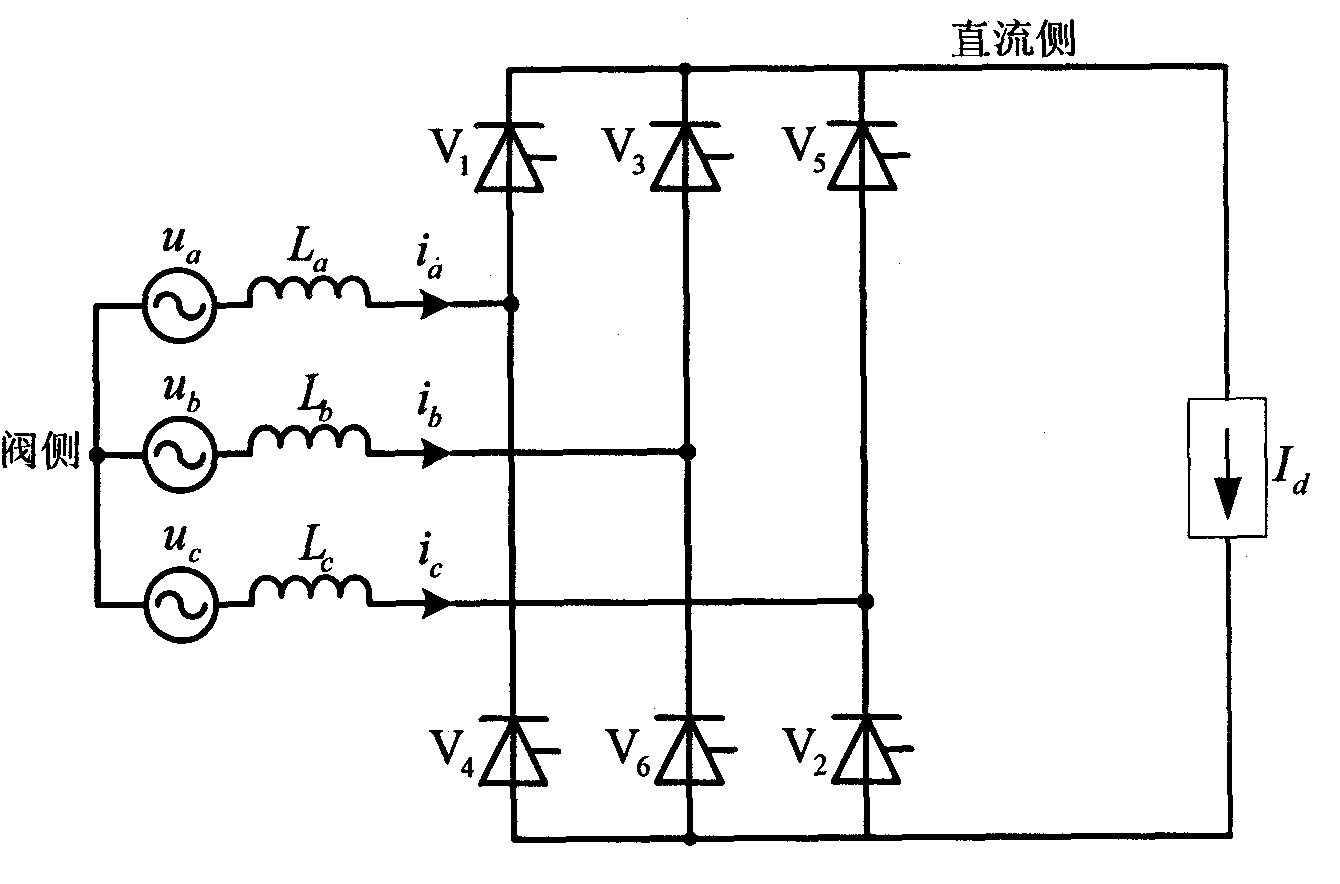

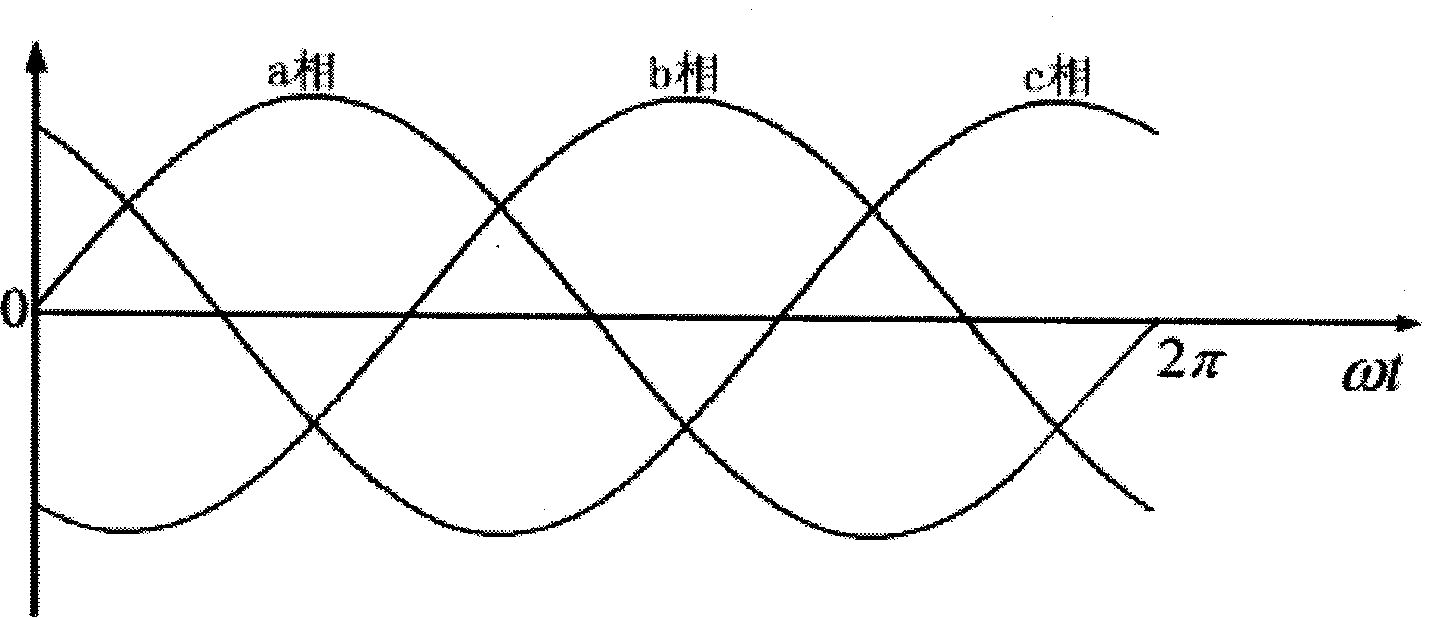

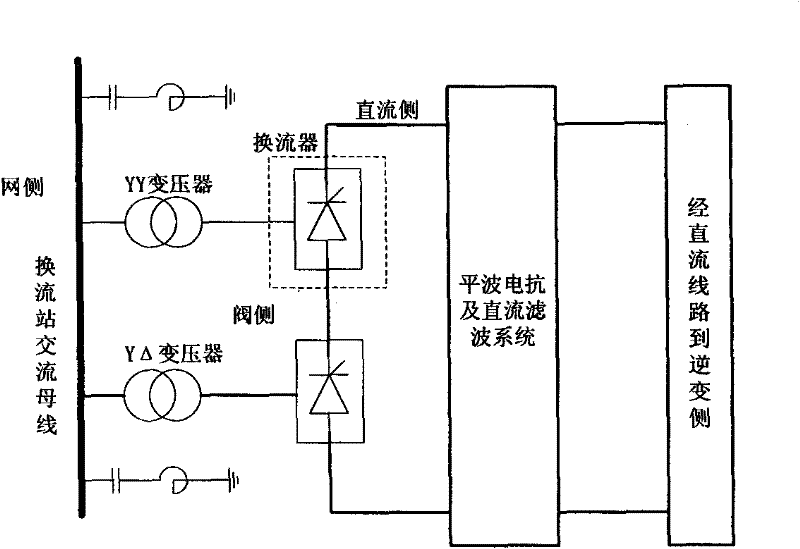

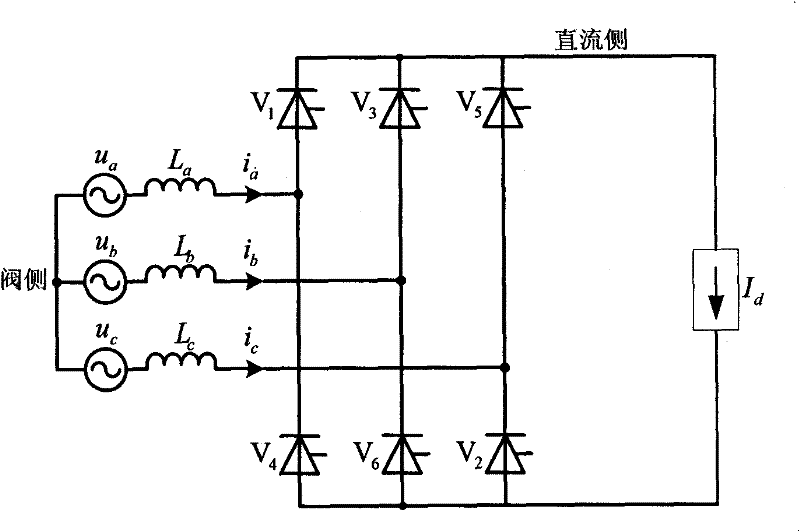

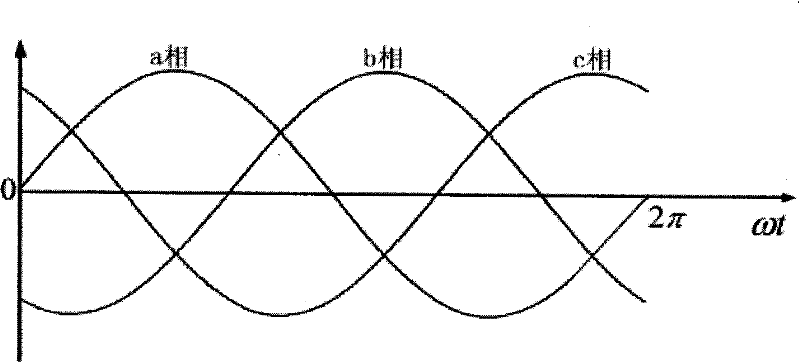

Determination method of high voltage direct current converter commutation overlap angle

InactiveCN101834437ASimple designImprove performanceDc circuit to reduce harmonics/ripplesWork periodHigh-voltage direct current

The invention discloses a determination method of a high voltage direct current converter commutation overlap angle, aiming to solve the problem that a traditional method for calculating a commutation overlap angle can not take nonideal factors including background harmonics into consider to cause poor design performance of a wave filter. The method comprises the following steps of dividing the working period of a converter into six commutation sections and six non-commutation sections; establishing a differential equation to each commutation section by considering factors such as background harmonic interference, asymmetric fundamental voltage, asymmetric converter trigger angle distances, commutation impedance deviation and the like; and accurately calculating the commutation overlap angle. The invention efficiently enhances the calculation efficiency when ensuring the accuracy and can enhance the design quality of an alternating current converter.

Owner:ZHEJIANG UNIV

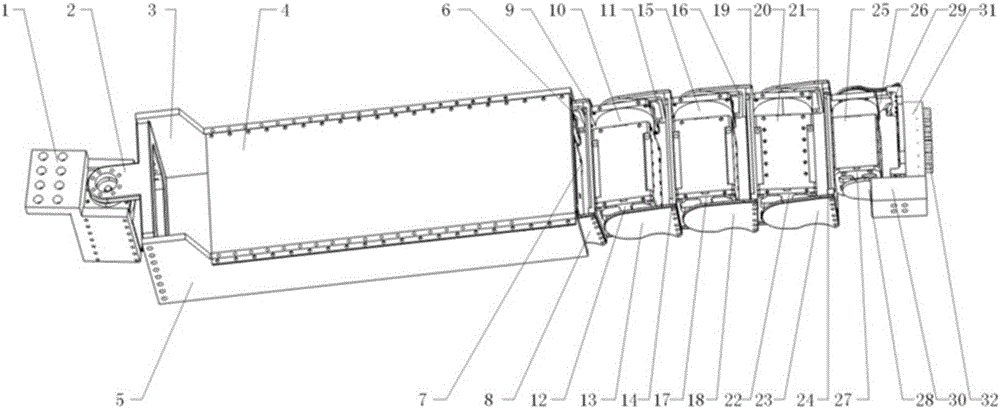

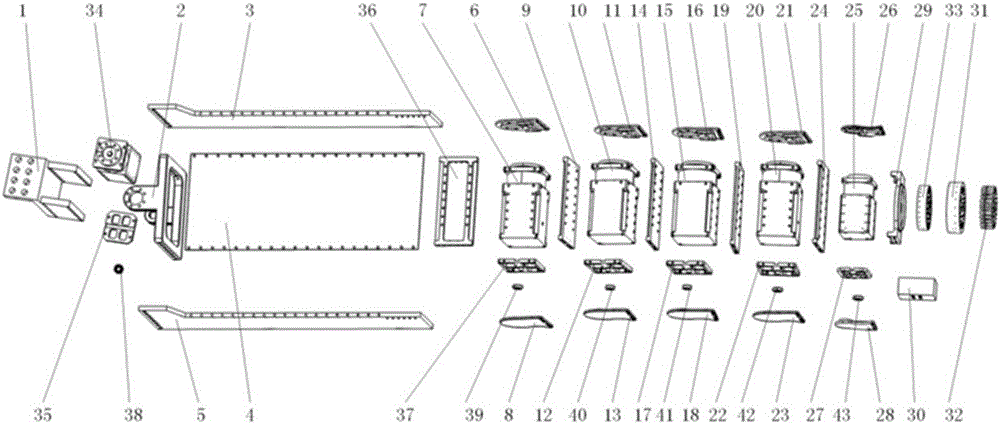

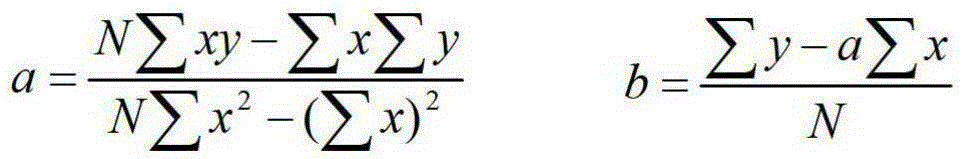

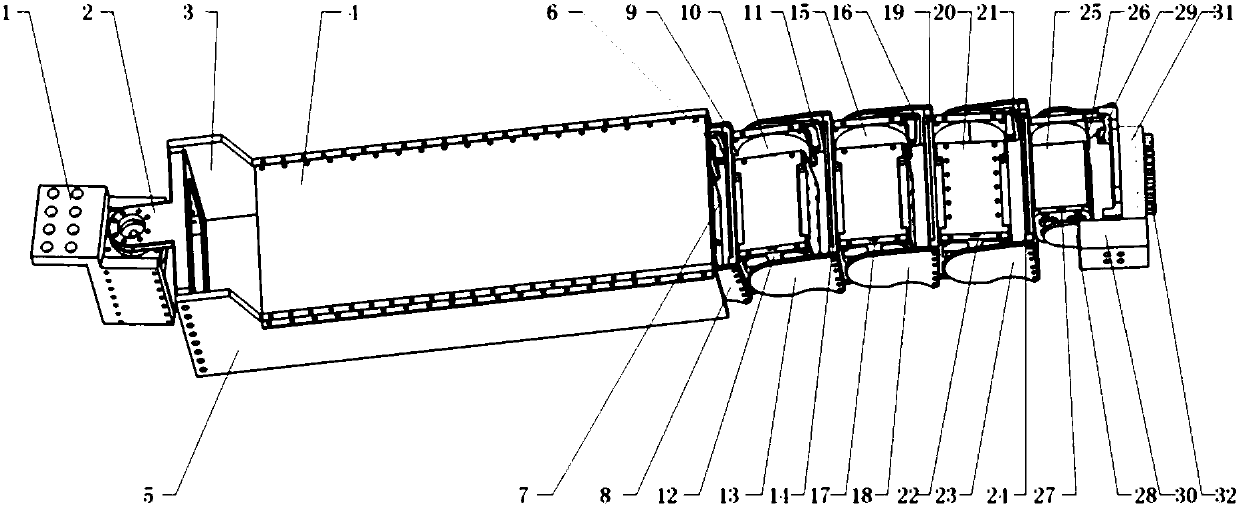

Folding automatic charging mechanical arm and electric vehicle carried with same

InactiveCN105691228ARealize automatic chargingRealize automatic power offVehicle connectorsCharging stationsControl engineeringElectric vehicle

The invention relates to a folding automatic charging mechanical arm and an electric vehicle vehicleried with the mechanical arm. The mechanical arm is arranged at the bottom of the electric vehicle, and charging of the electric vehicle is achieved by plugging the mechanical arm into a socket. The mechanical arm comprises a swing arm fixing plate, a head joint, a connection plate, a parallel joint unit, a plug and a camera, wherein one end of the swing arm fixing plate is fixed to the bottom of the electric vehicle; one end of the head joint is connected with the other end of the swing arm fixing plate so that the mechanical arm can rotate around the head joint; the connection plate is an inverted U-shaped strip slot, and is connected with the head joint; the parallel joint unit is connected with the connection plate in a sliding mode; the parallel joint unit is located in the connection plate when the electric vehicle is not charged, and extends out of the connection plate and rotates around parallel joints when the electric vehicle needs to be charged; the plug is mounted at the tail end of the parallel joint unit; and the camera is mounted on one side face of the plug. Compared with the prior art, automatic charging is realized, a charging device is small in size, and using is convenient. The vehicle-mounted automatic charging mechanical arm fills up the blank in China and is of great significance on promoting the technological development of electric vehicles.

Owner:SHANGHAI INT AUTOMOBILE CITY GRP CO LTD +1

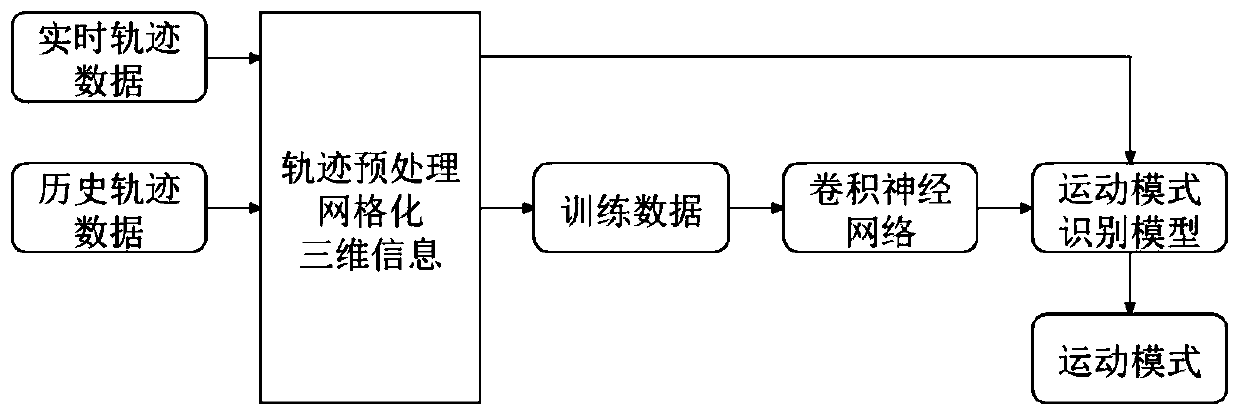

Track motion mode recognition method and device

PendingCN110866477AMentioned accuracyImprove accuracyCharacter and pattern recognitionNeural architecturesComputer graphics (images)Engineering

The invention relates to a track motion mode recognition method and device, and belongs to the technical field of artificial intelligence. The track motion mode recognition method includes the steps:through a deep learning mode, automatically extracting depth features of preprocessed to-be-identified track data, wherein the obtained depth features have a better identification degree, so that theaccuracy of mode identification can be significantly improved; and meanwhile, when carrying out pretreatment, converting the track data into the grid data containing the multi-dimensional information,wherein the positions of the grids represent the positions of the users, and the grid sequence reflects the geographic space characteristics and the geometrical characteristics of the user track, andthe pixels of the grid represent the average speed of the user in the grid and reflect the kinematicity characteristics of the user track, so as to guarantee that the converted track data can fully express the representative characteristics of the mobile user track, and the accuracy of pattern recognition is further improved.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

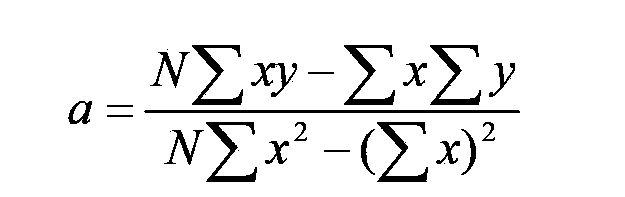

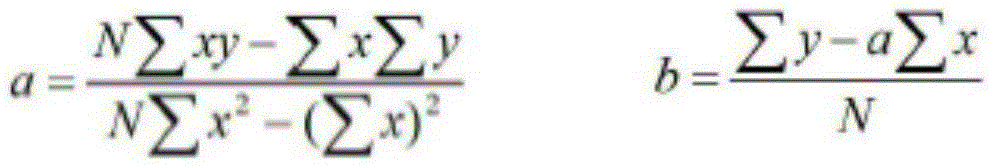

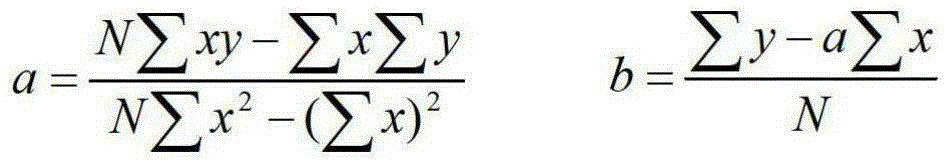

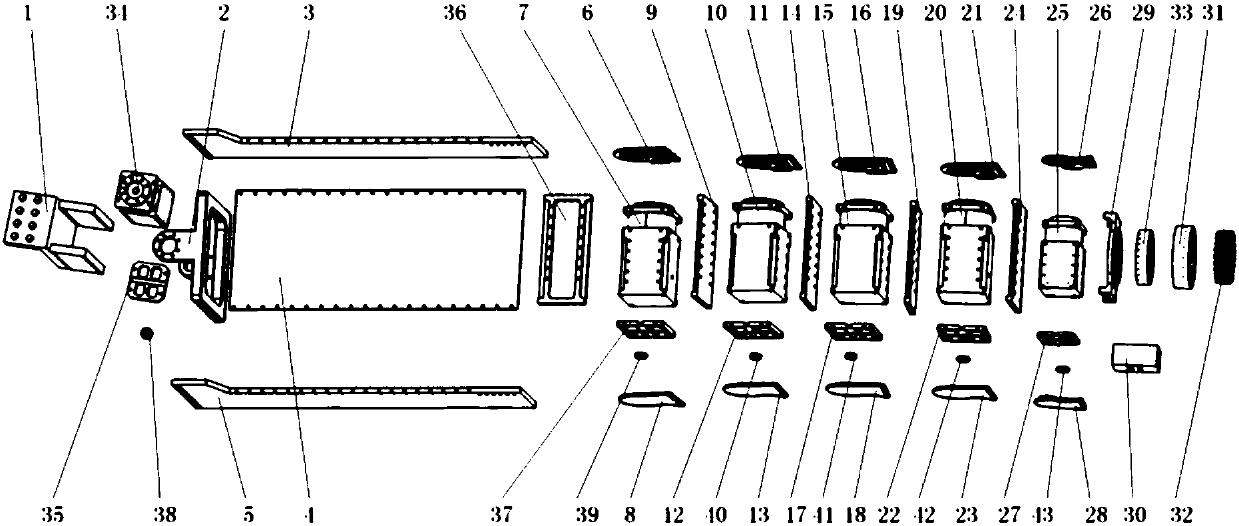

Method for assessing service lives of fuses by determining activation energy of melts

The invention discloses a method for assessing service lives of fuses by determining activation energy of melts. The method comprises the steps that accelerating aging test of different accelerated stresses is conducted on a plurality of sets of fuses, metal electromigration service lives of the melts under different temperatures are obtained according to a plurality of sets of test data, the activation energy of the melts is calculated in the curve fitting method, parameters of service life assessing models of the fuses are determined, and therefore the service lives of the melts under different conditions can be calculated, and the activation energy of the melts is determined in a test method to assess the service lives of the fuses. Compared with empirical data adoption in the prior art, the method can improve accuracy of assessment of the service lives of the fuses.

Owner:SUZHOU NUCLEAR POWER RES INST +1

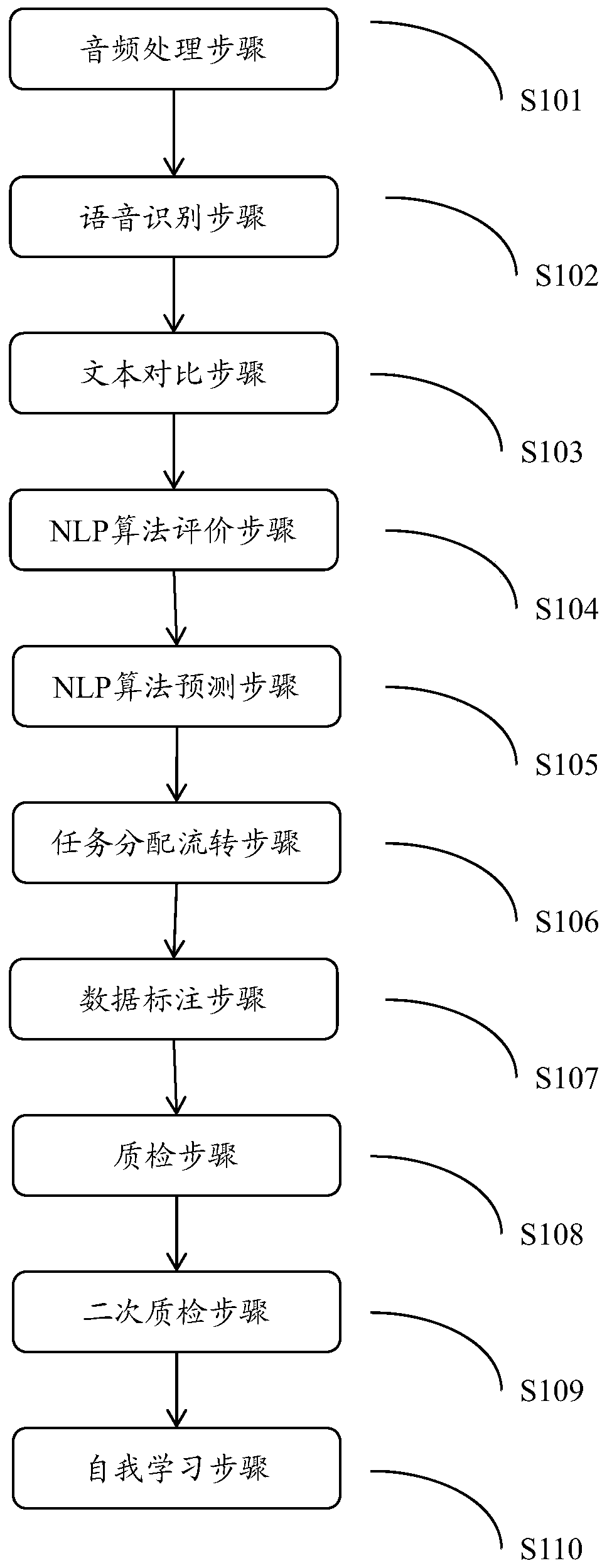

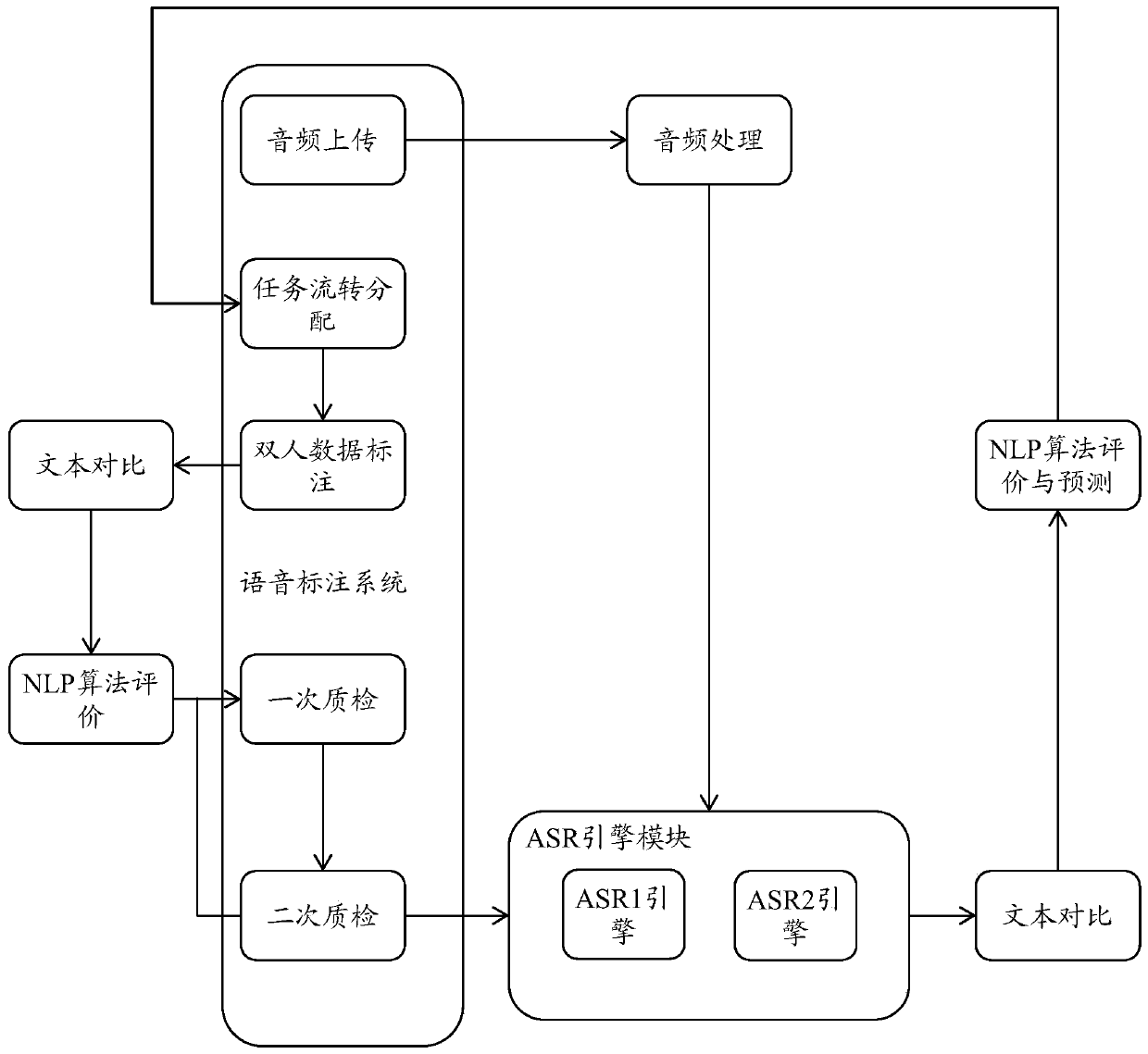

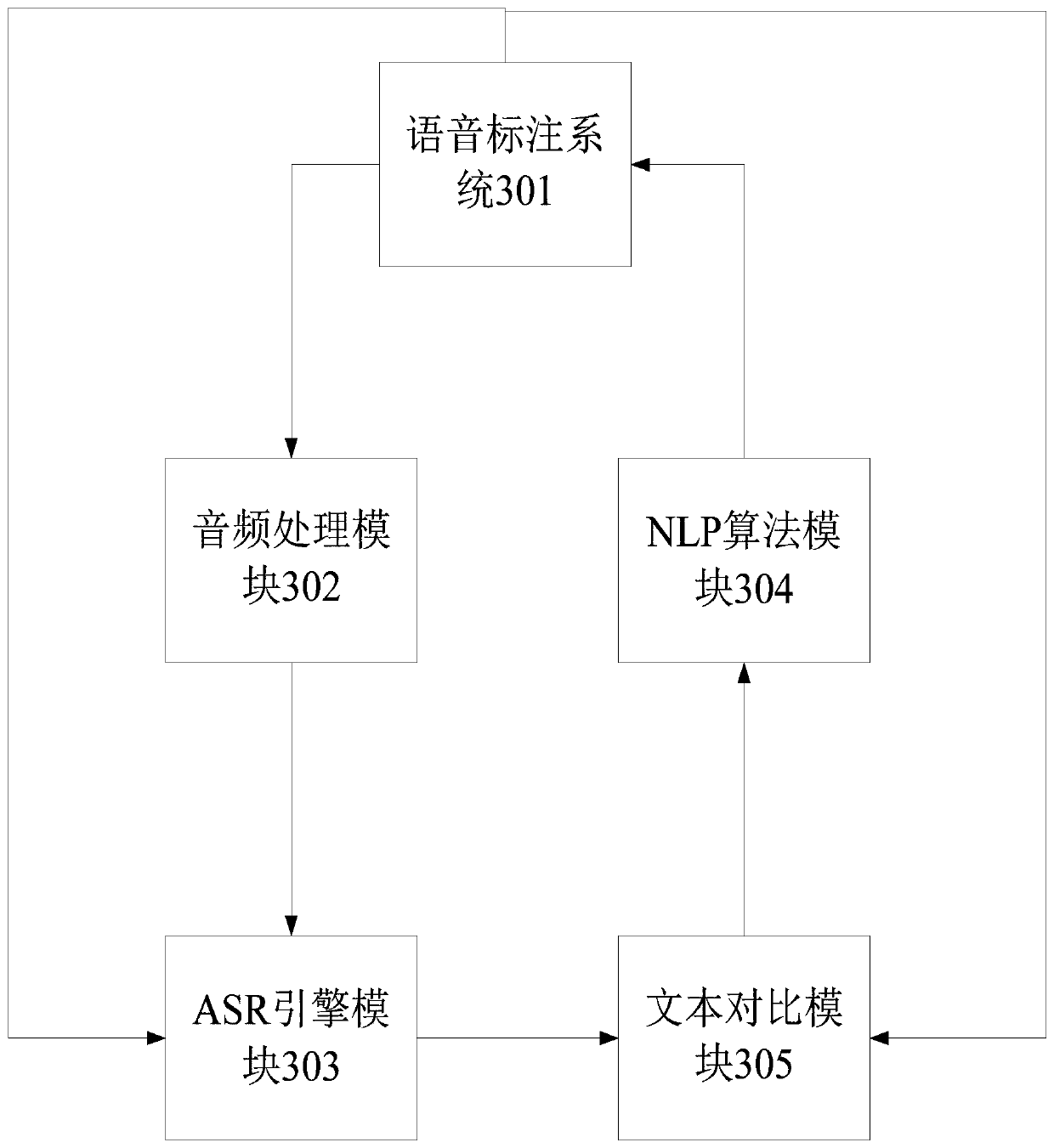

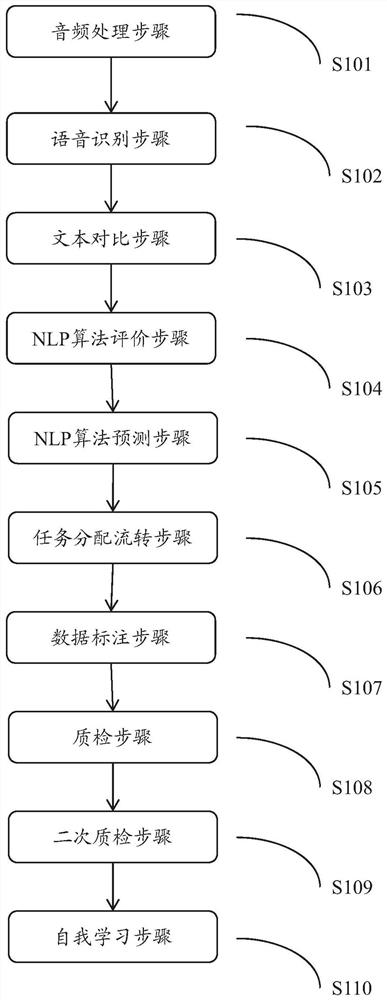

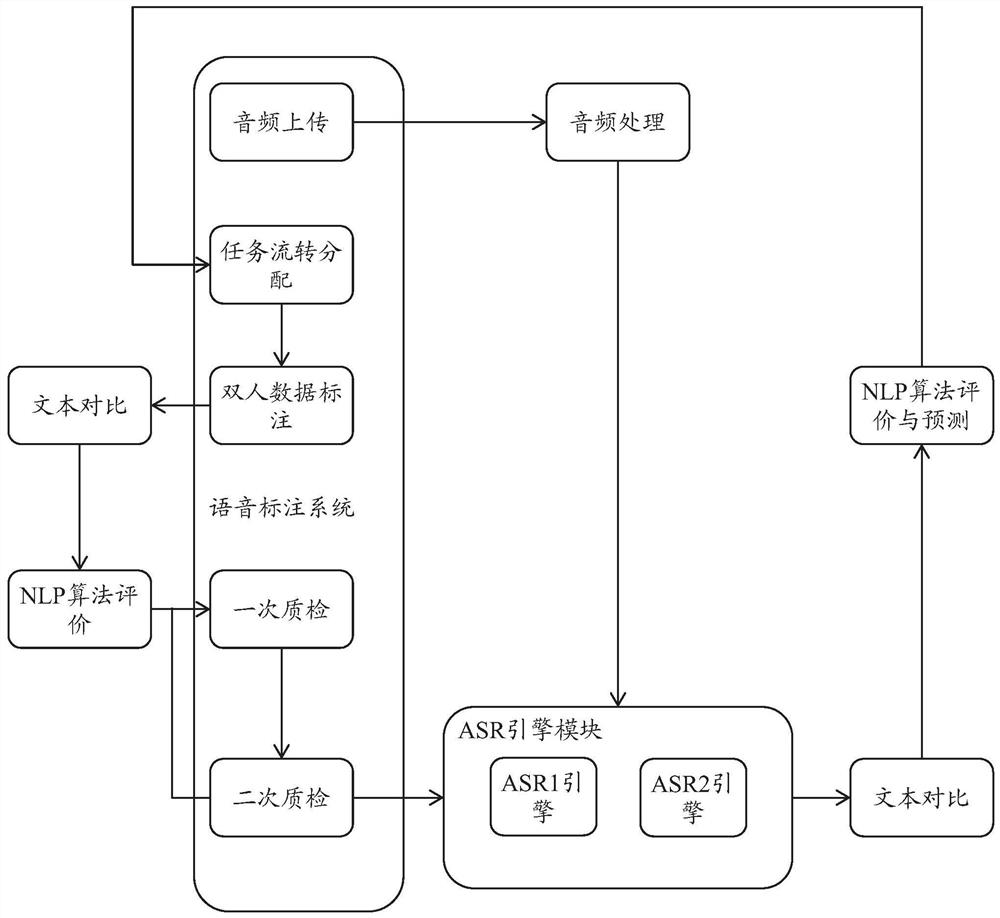

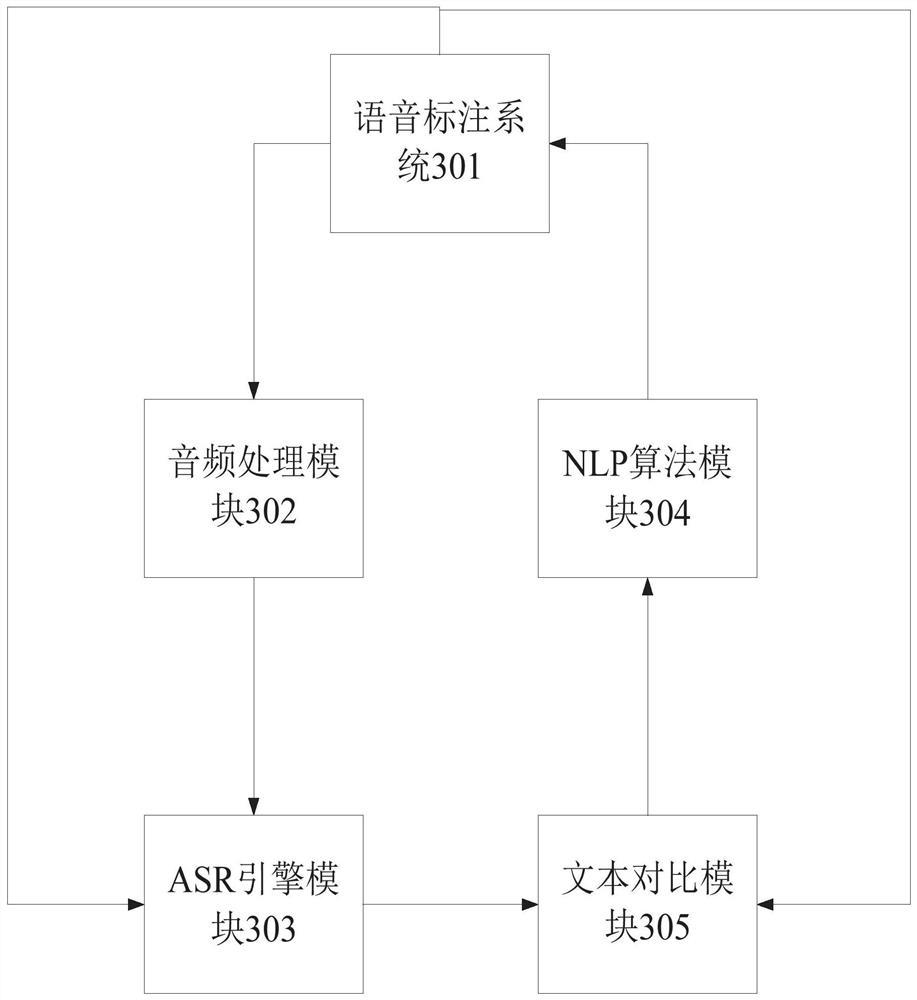

Data labeling method and device based on self-learning algorithm

ActiveCN109830230ASave labeling timeImprove labeling efficiencySpeech recognitionSpecial data processing applicationsProduction effectTraining Supports

The invention relates to the field of voice signal processing, in particular to a data labeling method and device based on self-learning algorithm. The method comprises a speech recognition step, a text comparison step, a natural language processing algorithm evaluation step, a natural language processing algorithm prediction step, a data labeling step, a quality inspection step and a self-learning step. The text comparison step is used for comparing a plurality of recognition texts, labeling difference parts of texts and performing sentence breaking processing. The data labeling step is usedfor performing data labeling on an optimal pre-labeled text for a plurality of times by referring to an original recognition text and a prediction text of the difference parts, so as to form a plurality of groups of data labeling texts. The self-learning step is used for inputting the optimal labeled text and a corresponding audio signal into a speech recognition engine, wherein the speech recognition engine is iteratively trained based on the self-learning algorithm. According to the labeling method and device, the data labeling time is greatly saved, the data labeling quality and the data labeling efficiency are effectively improved, the training support is provided for various artificial intelligence products, and the production effect of intelligent products is improved.

Owner:深圳平安综合金融服务有限公司

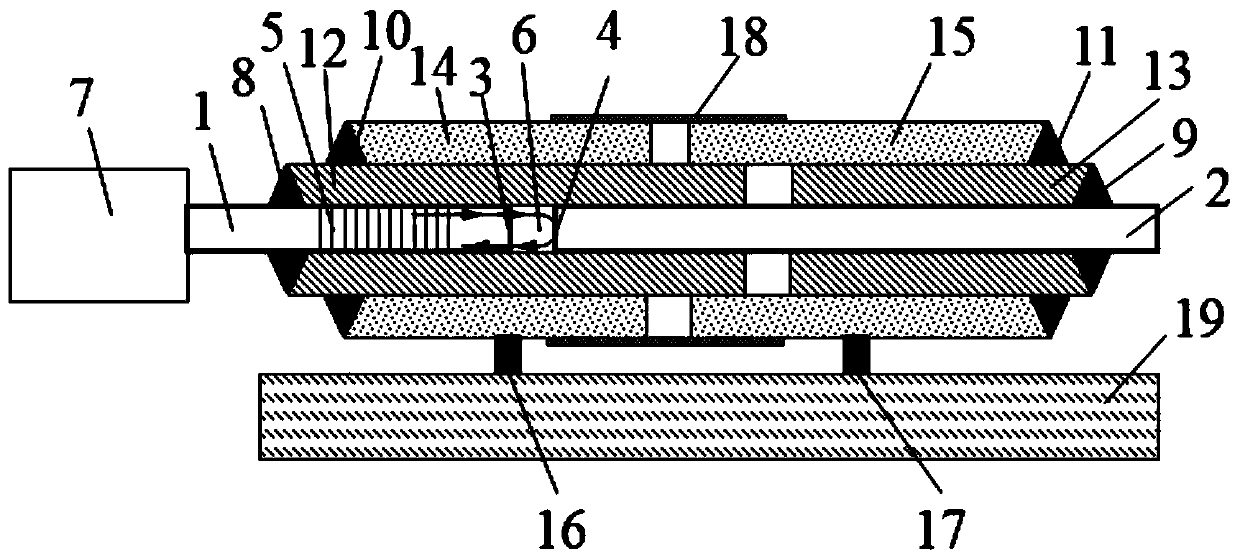

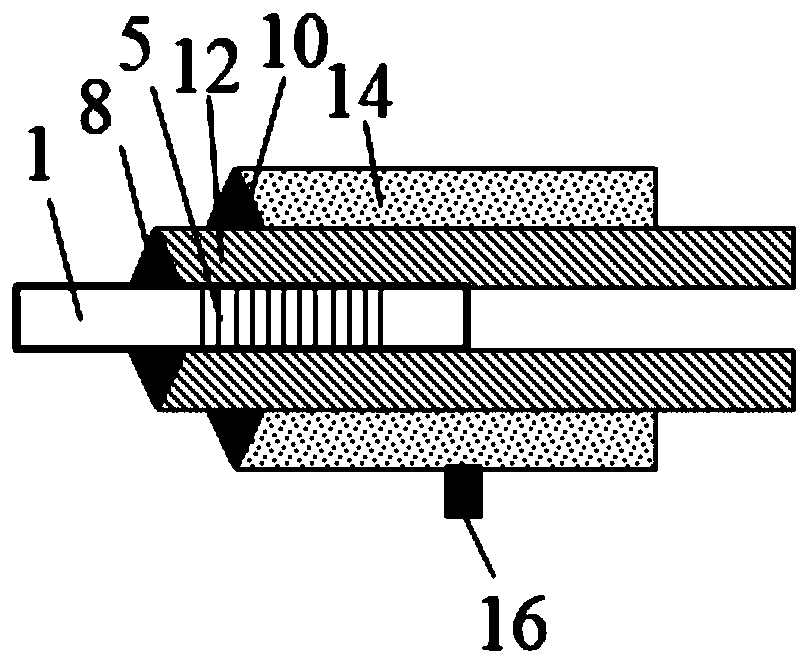

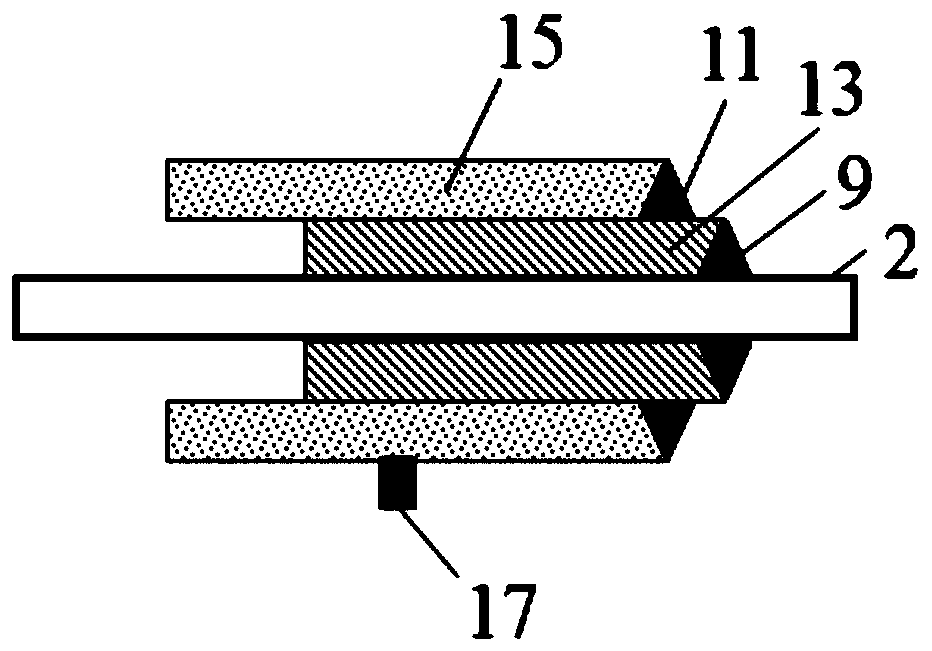

F-P cavity type high-temperature large-strain optical fiber sensor

The invention belongs to the technical field of sensors, and discloses an F-P cavity type high-temperature large-strain optical fiber sensor, which comprises a transmission optical fiber, a reflectingmirror, an inner sleeve, an outer sleeve, a clamp for fixing the outer sleeve and a sealing structure; the transmission optical fiber can ensure the coaxiality through mutual embedding of the two sets of sleeve devices, and a Fabry-Perot cavity, namely an F-P cavity, is formed between the end face of the optical fiber and the reflecting mirror. The cavity length of the F-P cavity can be changed due to deformation of a measured material, so that the change of a reflection spectrum is caused, and the strain of the material is monitored by analyzing the variation of the spectrum. The F-P cavitytype high-temperature large-strain optical fiber sensor is based on a high-temperature strain gauge of a Fabry-Perot interference principle, and can measure material deformation of tens of thousands to hundreds of thousands of micro-strain levels at high temperature. The optical fiber sensor can realize measurement of large strain at high temperature and simultaneous measurement of temperature andstrain parameters, and is high in measurement precision, high in stability and easy to popularize.

Owner:DALIAN UNIV OF TECH

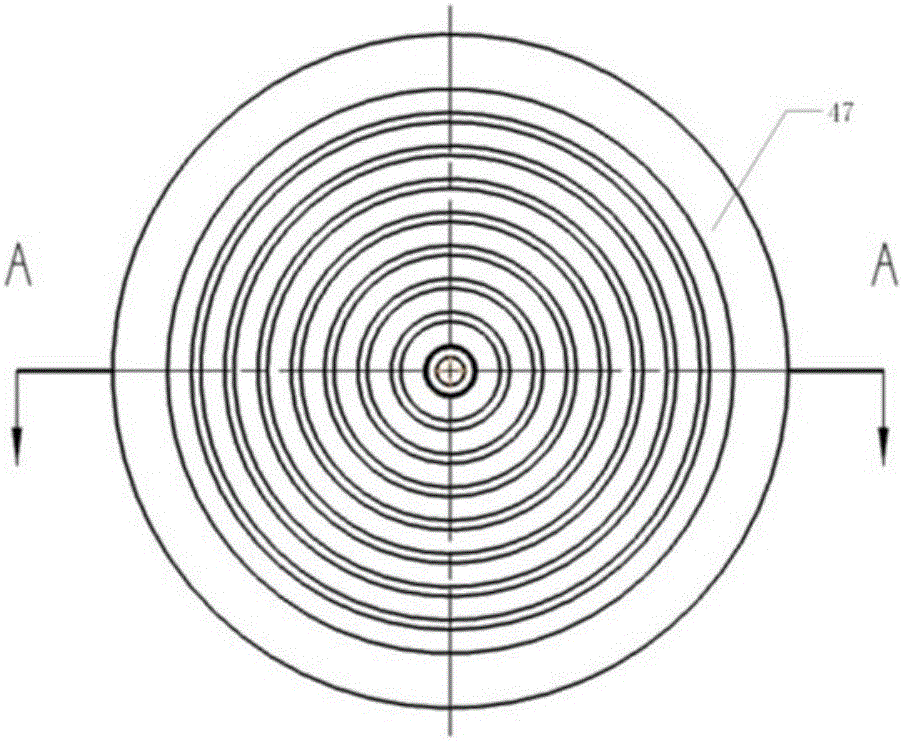

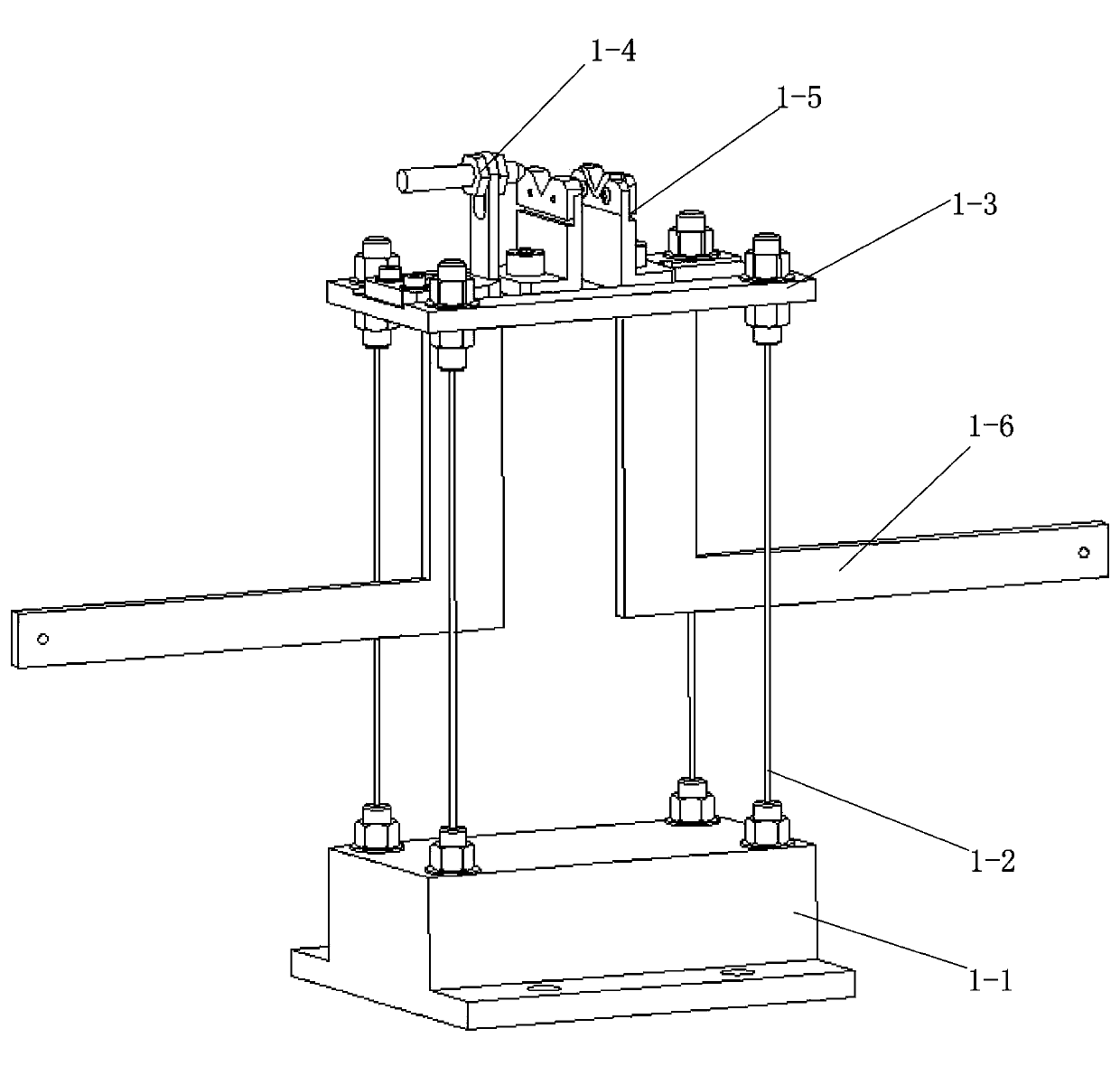

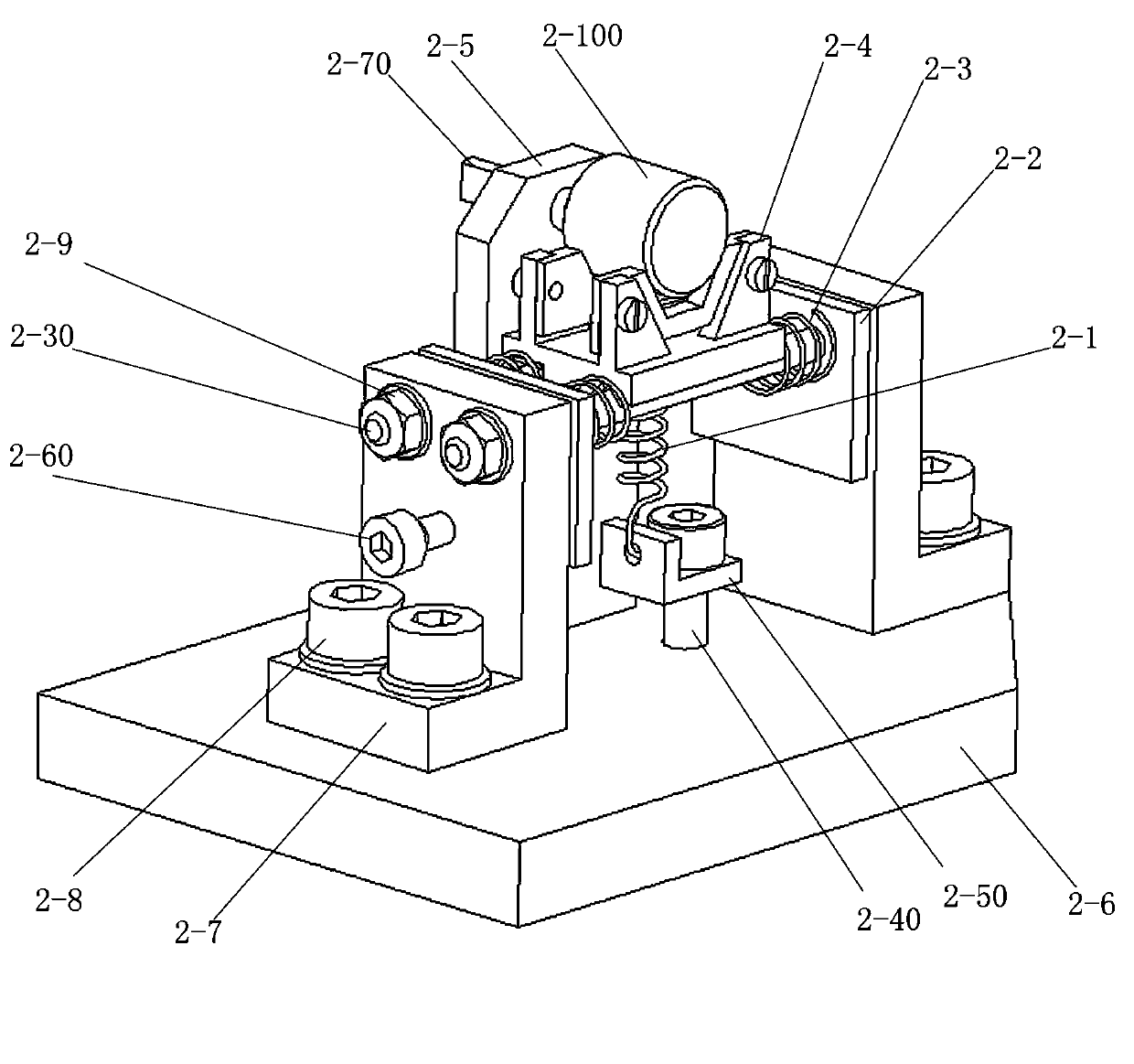

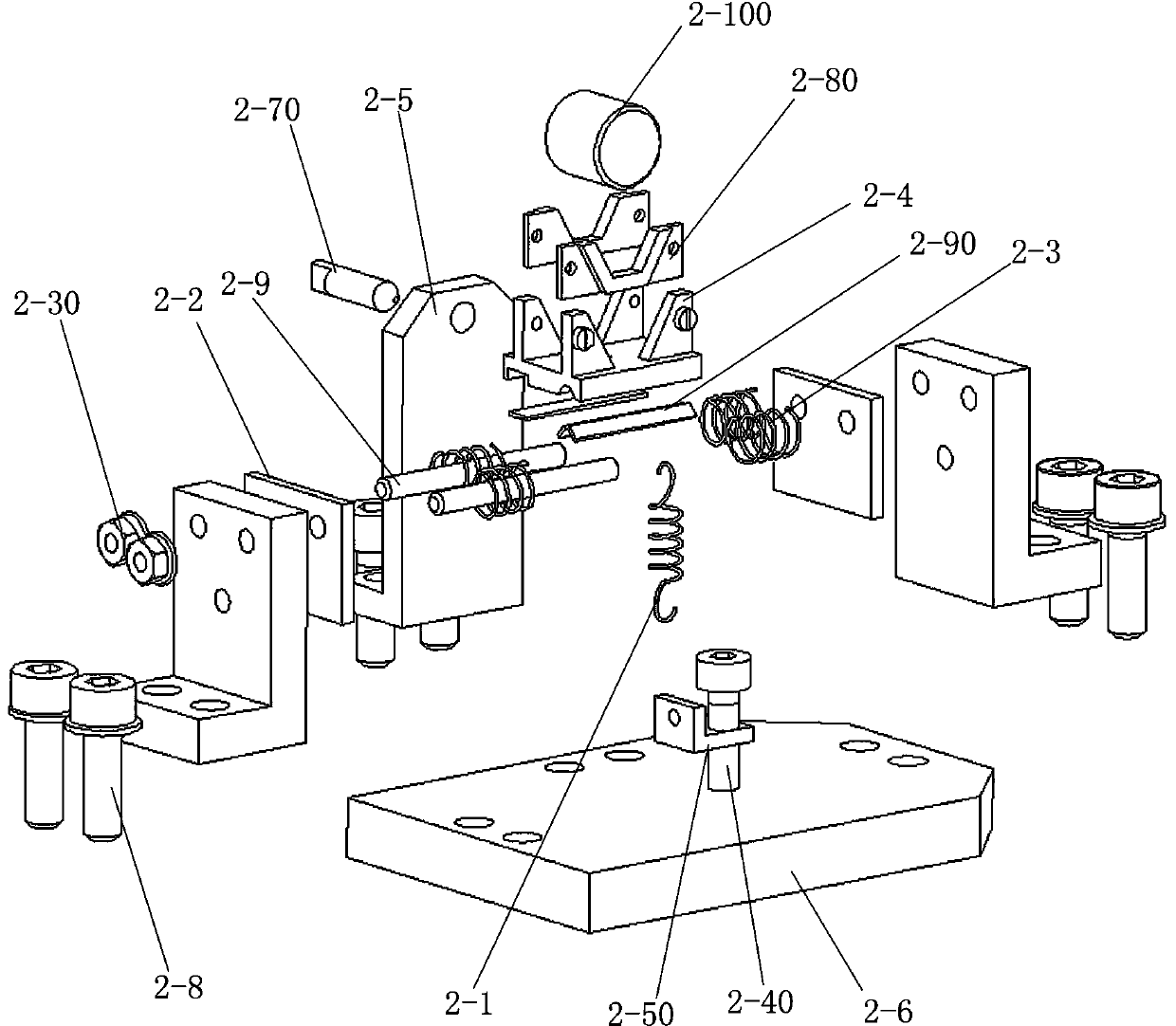

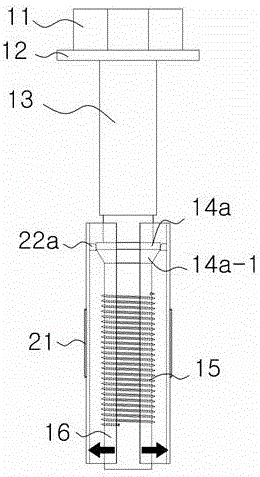

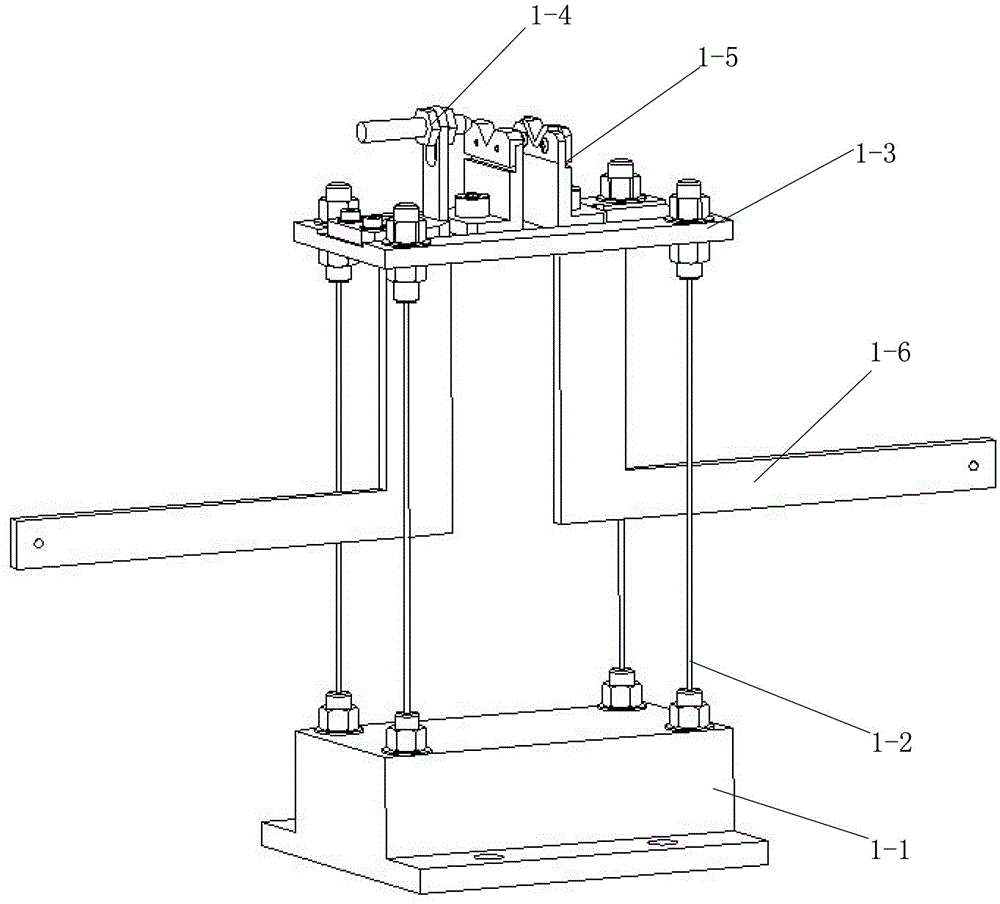

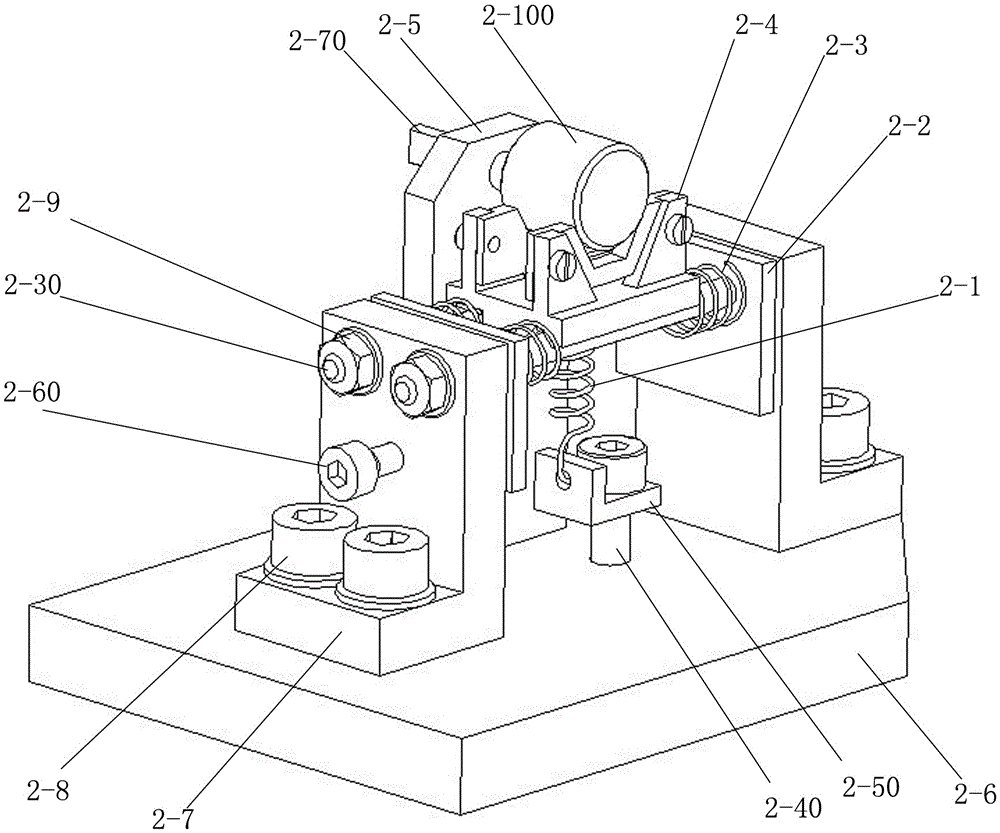

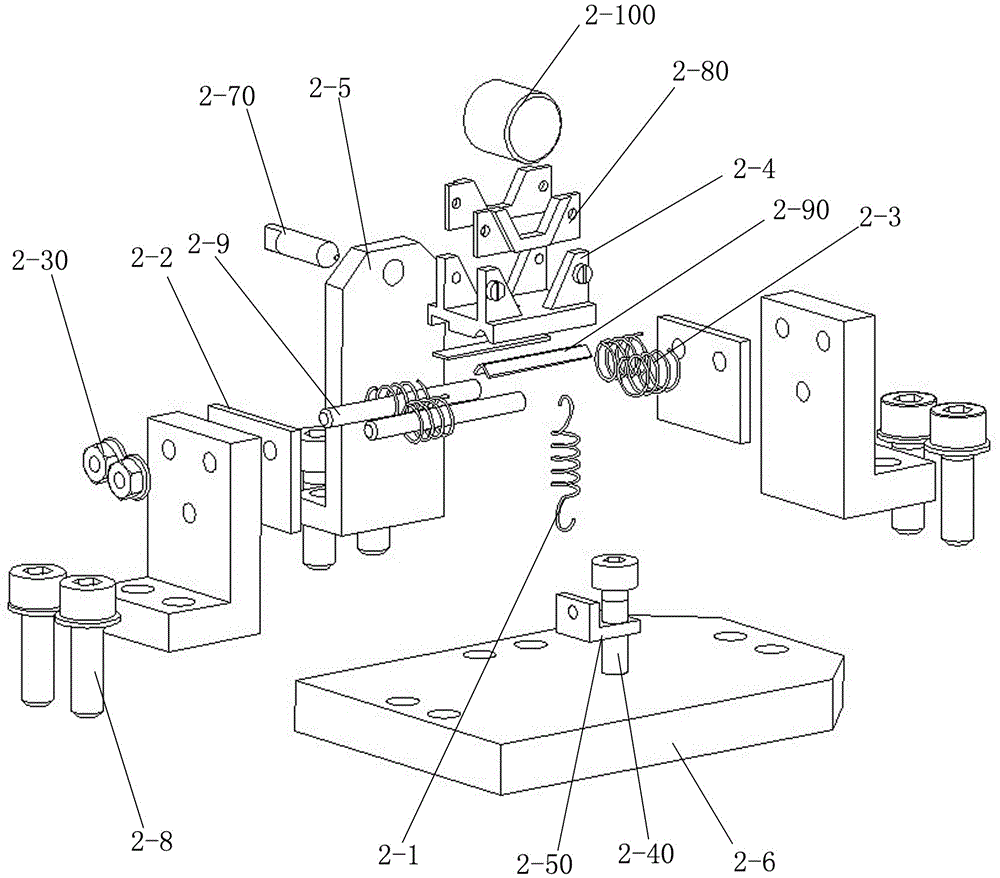

A swing frame for mini-sized rotor dynamic balancing machine

ActiveCN103389182AHigh sensitivityLarge amplitudeStatic/dynamic balance measurementBalancing machineDynamic balance

The invention discloses a swing frame for a mini-sized rotor dynamic balancing machine. A machine frame of the swing frame is a rigidity guide frame which is fixedly arranged; the machine frame is matched with supporting blocks in a guiding mode at a horizontally swinging linear direction of the supporting blocks through a guide mechanism; the guide mechanism comprises the machine frame, guide rods and guide channels; the guide rods and the guide channels are correspondingly formed on the supporting blocks and extend along the swing direction of the supporting blocks; the number of the guide blocks is at least two; the guide rods are separately arranged by two guide rods; the guide channels and the guide rods are arranged in a one-to-one correspondence mode; damping devices are damping units which are arranged at two back-to-back sides of the swing direction of the supporting blocks in an elastic damping check mode. Accordingly, the existing machine frame which has an elastic supporting function is replaced by the rigidity machine frame, the frame self-rigidity influence to guide swing of supporting blocks is reduced through guide movement of the supporting blocks on the machine frame, and the sensitivity of the integral swing frame during the processing of measuring the mini-sized rotor dynamic imbalance performance is improved.

Owner:HENAN UNIV OF SCI & TECH

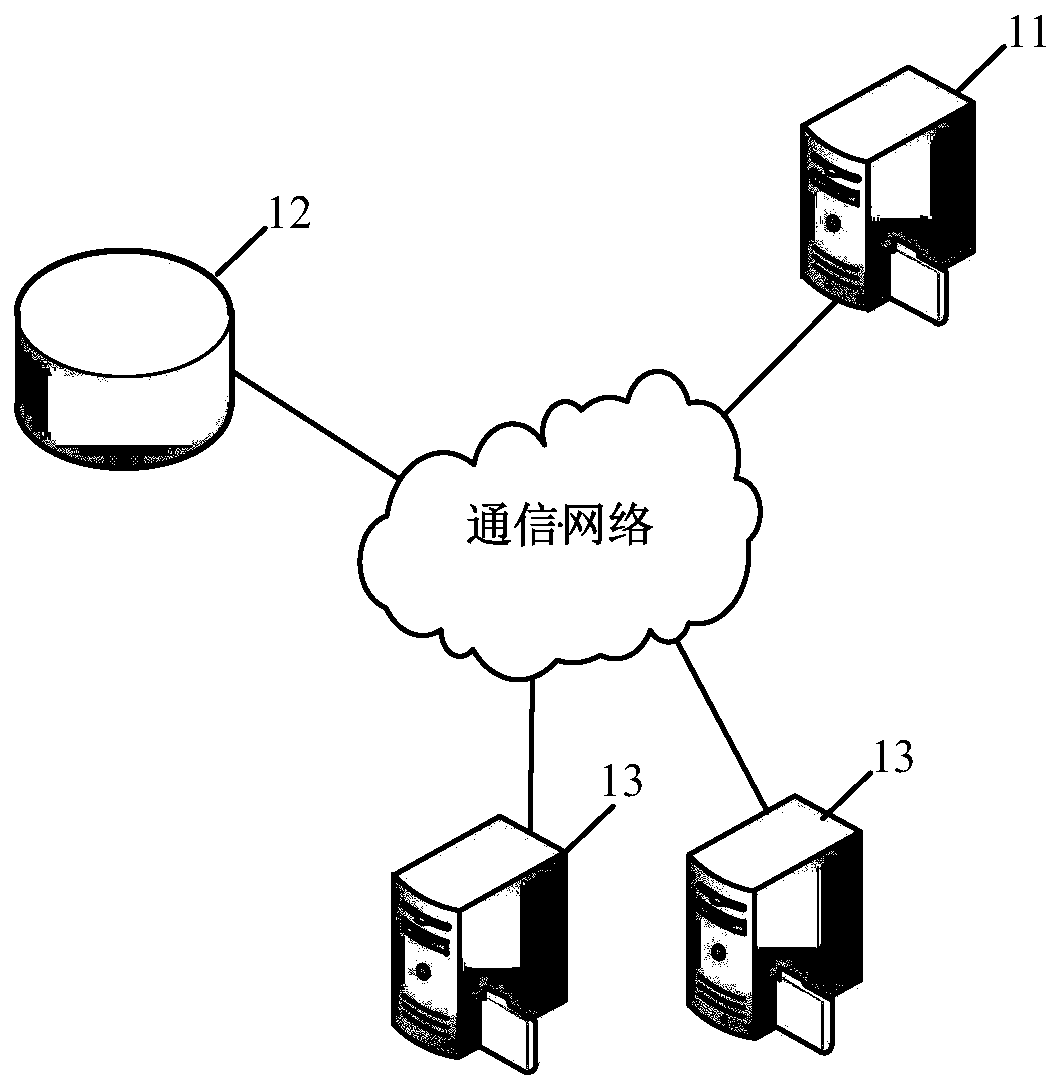

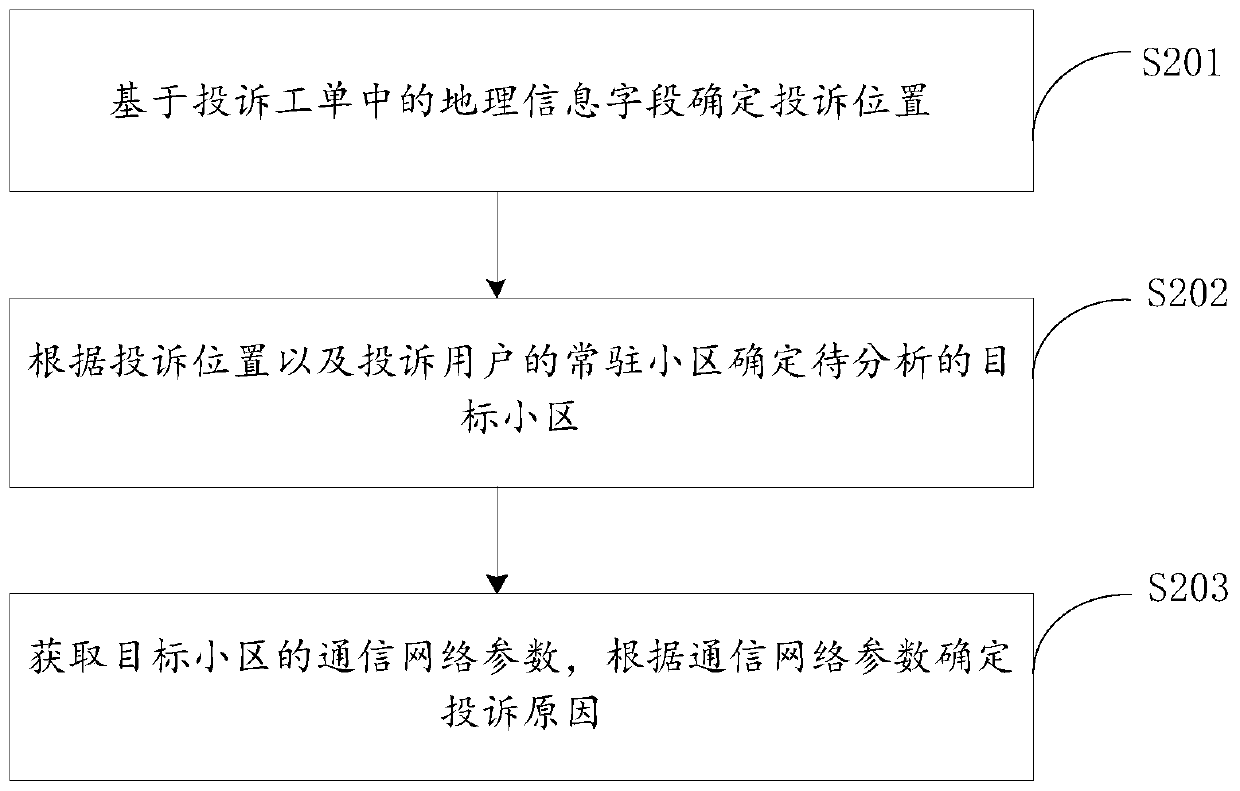

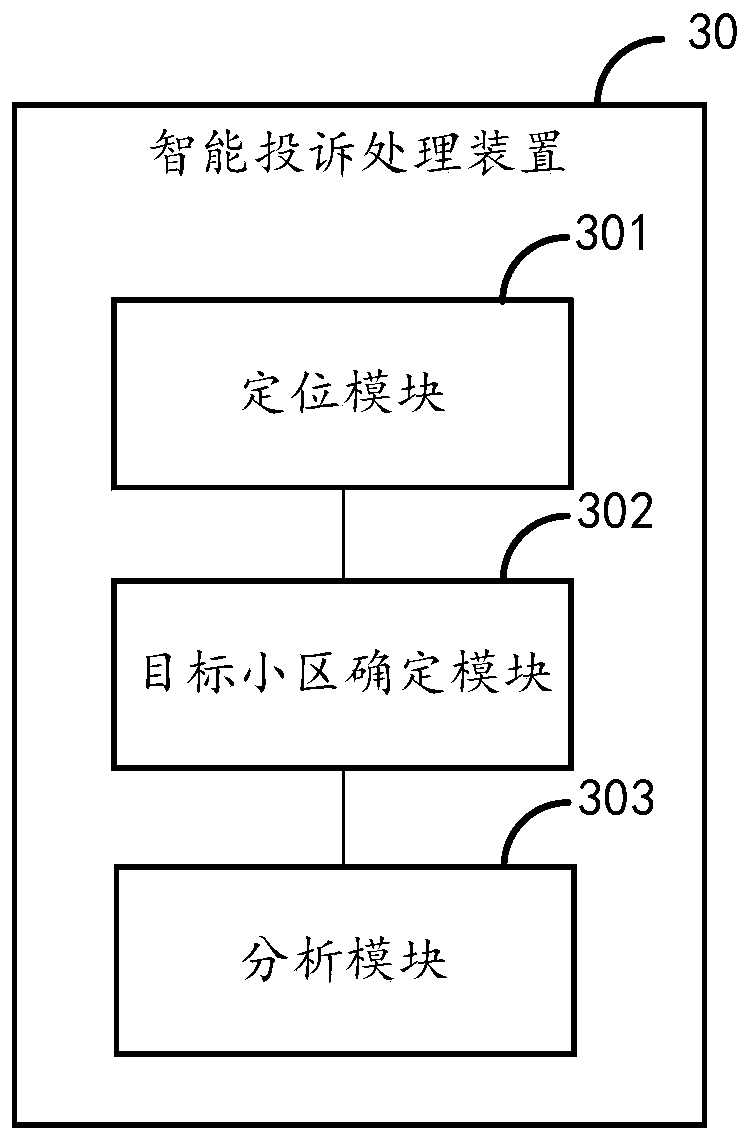

Intelligent complaint processing method and device, electronic equipment and storage medium

PendingCN111325561AImprove accuracyMentioned accuracyLocation information based serviceCommerceReal-time computingNetwork parameter

The invention relates to the technical field of communication, and discloses an intelligent complaint processing method and device, electronic equipment and a storage medium. The method comprises thesteps of determining a complaint position based on a geographic information field in a complaint work order; determining a target cell to be analyzed according to the complaint position and the resident cell of the complaint user; and acquiring communication network parameters of the target cell, and determining a complaint reason according to the communication network parameters. According to thetechnical scheme provided by the embodiment of the invention, the complaint position is automatically positioned, the positioning accuracy is improved in combination with the resident cell of the user, the analysis data is automatically acquired for integration and processing, and the complaint processing efficiency and the problem positioning accuracy are improved.

Owner:CHINA MOBILE GRP BEIJING +1

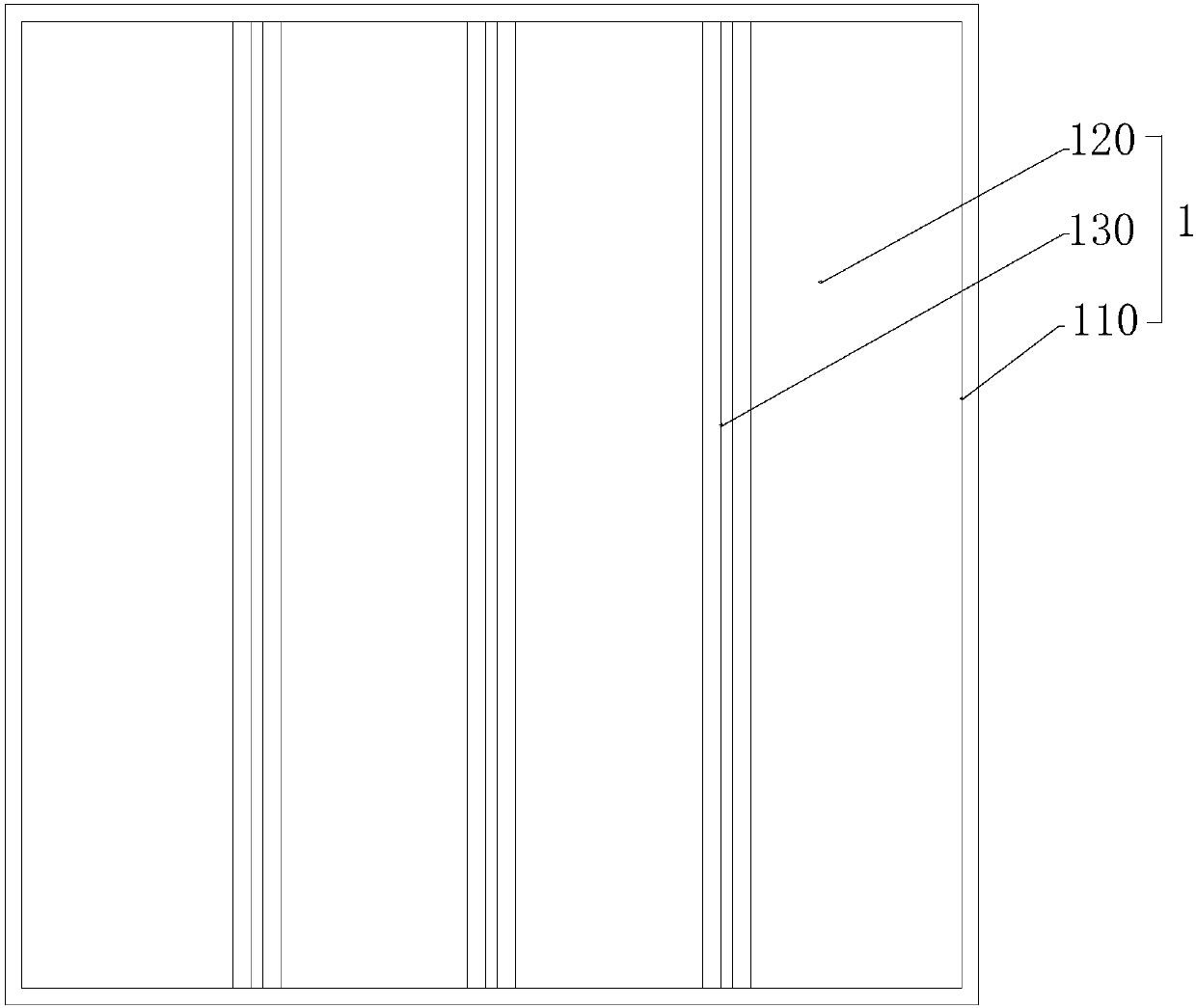

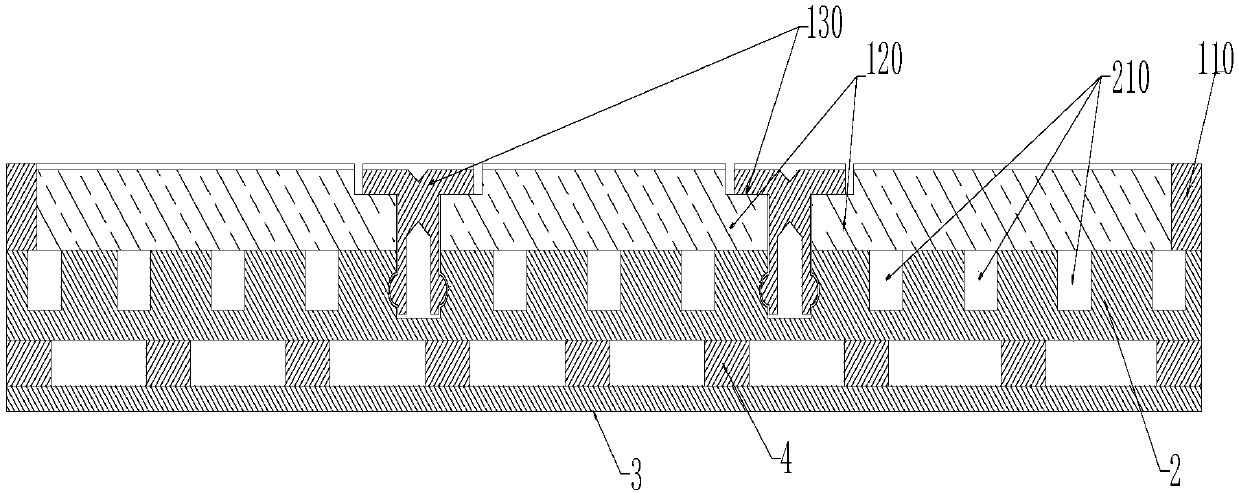

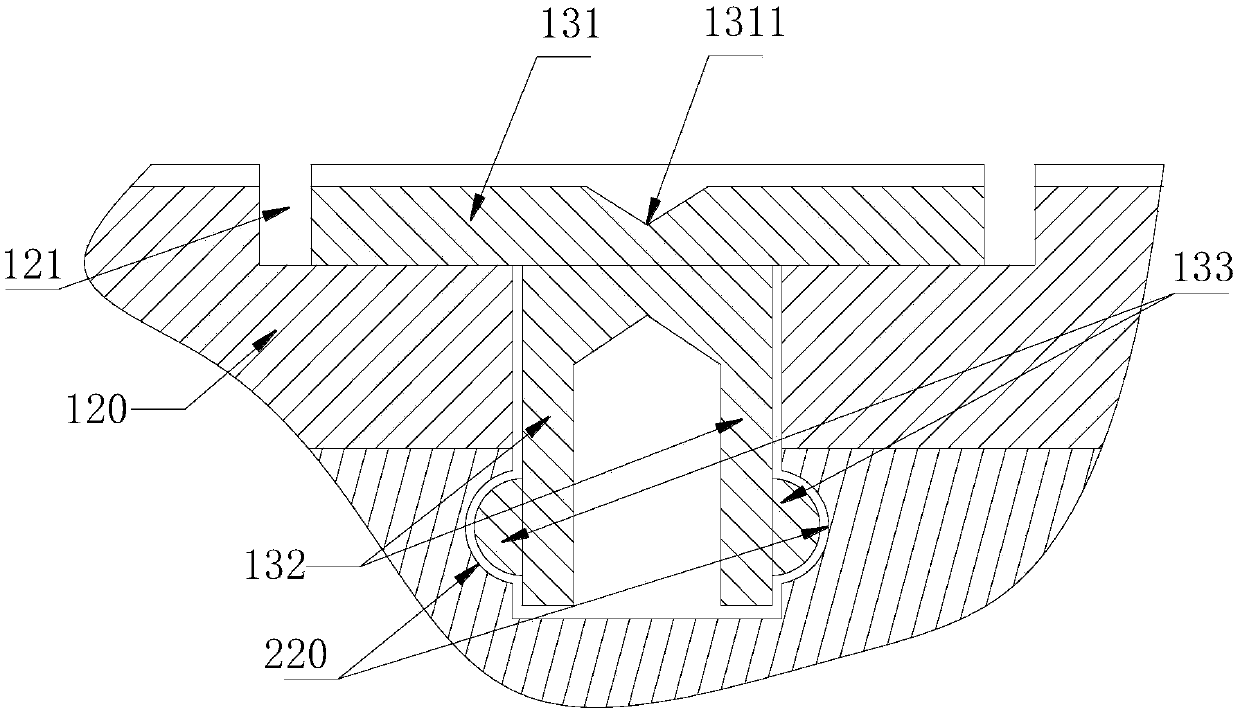

Artificial archaize laminate floor

InactiveCN107675857AImprove aestheticsSave resourcesCovering/liningsFlooring insulationsEngineeringPallet

Owner:WUHAN BAIQI TECH CO LTD

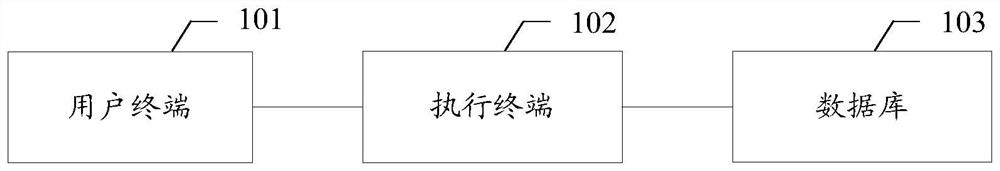

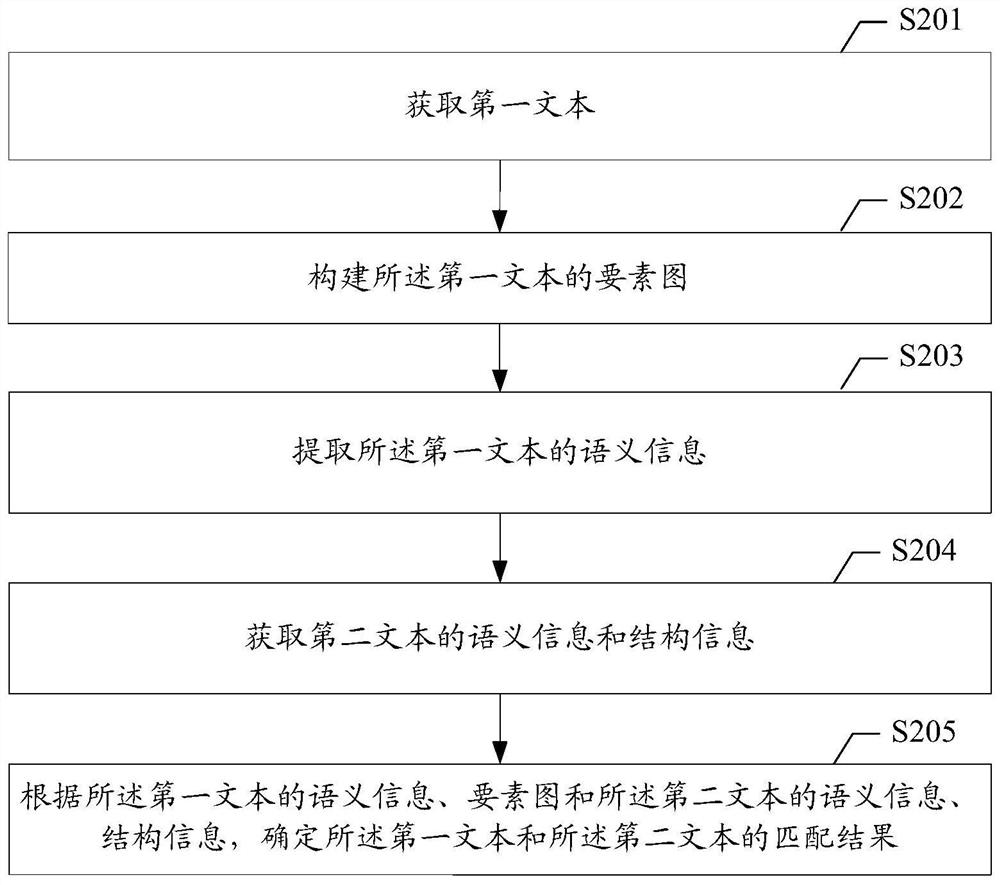

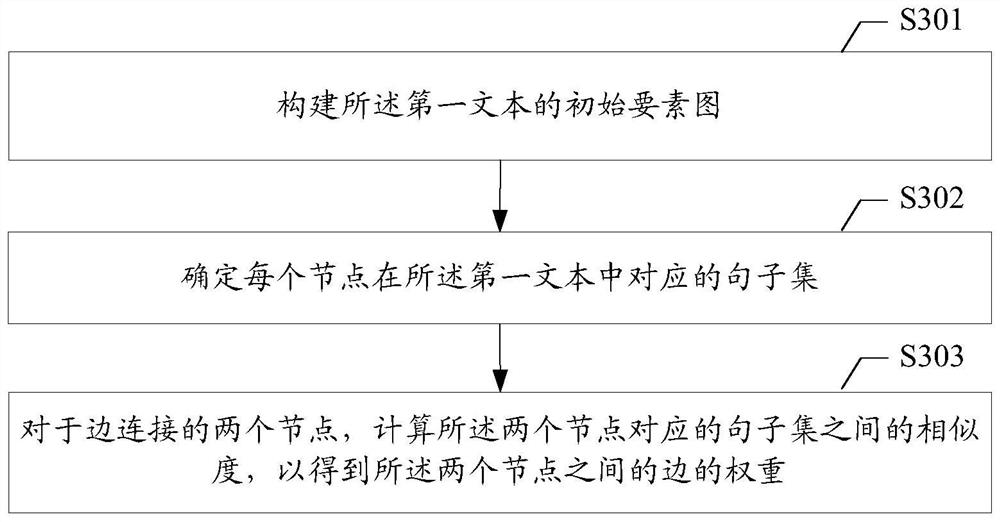

Text matching method and device, storage medium and terminal

PendingCN114661861AMentioned accuracyEasy to integrateSemantic analysisCharacter and pattern recognitionTheoretical computer scienceText matching

The invention discloses a text matching method and device, a storage medium and a terminal. The method comprises the steps of obtaining a first text; constructing an element graph of the first text; semantic information of the first text is extracted; semantic information and structural information of a second text are obtained, the structural information of the second text comprises an element graph and / or graph embedding feature information of the second text, and the graph embedding feature information is obtained through calculation according to the element graph; and determining a matching result of the first text and the second text according to the semantic information and the element graph of the first text and the semantic information and the structure information of the second text. Through the scheme provided by the invention, the text matching accuracy can be improved.

Owner:HUA DATA TECH (SHANGHAI) CO LTD

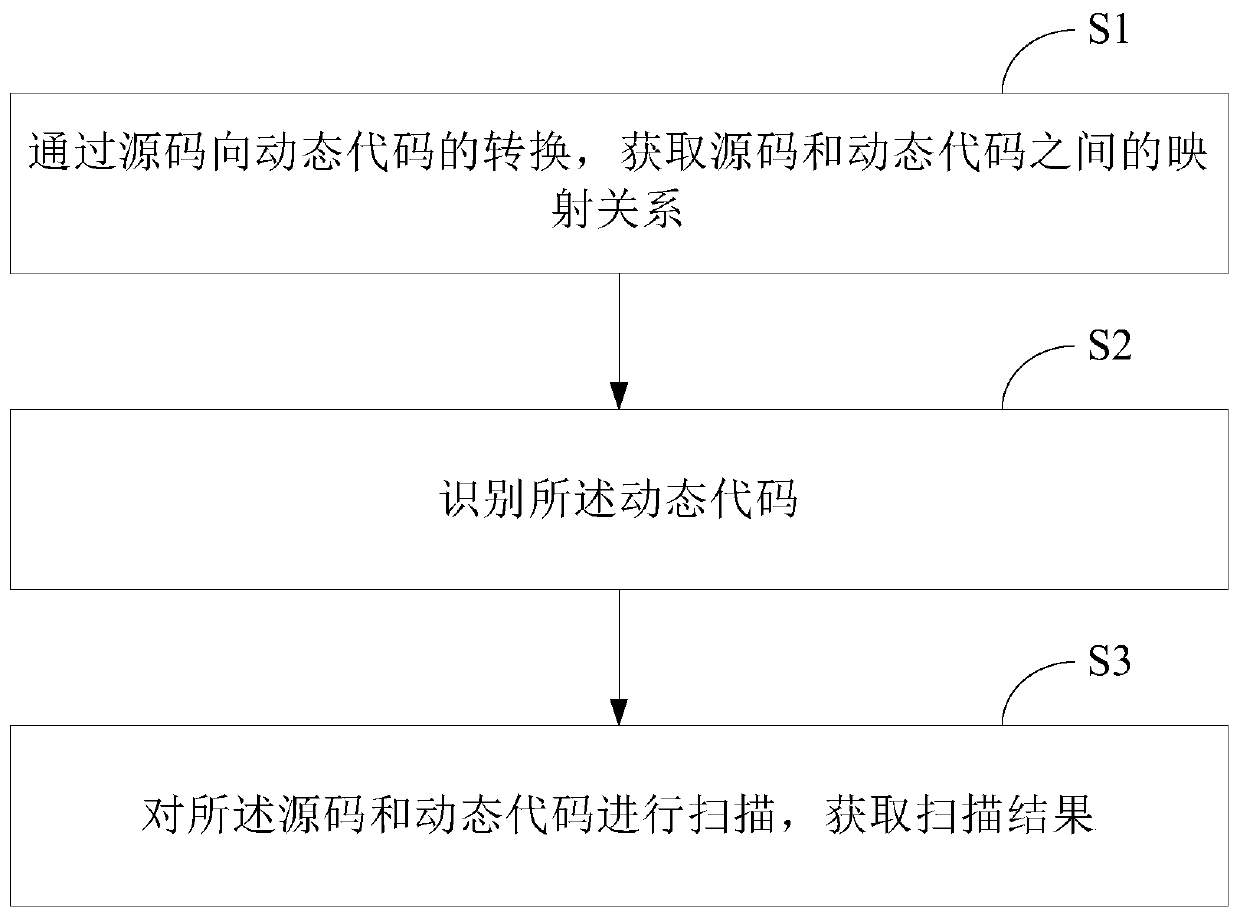

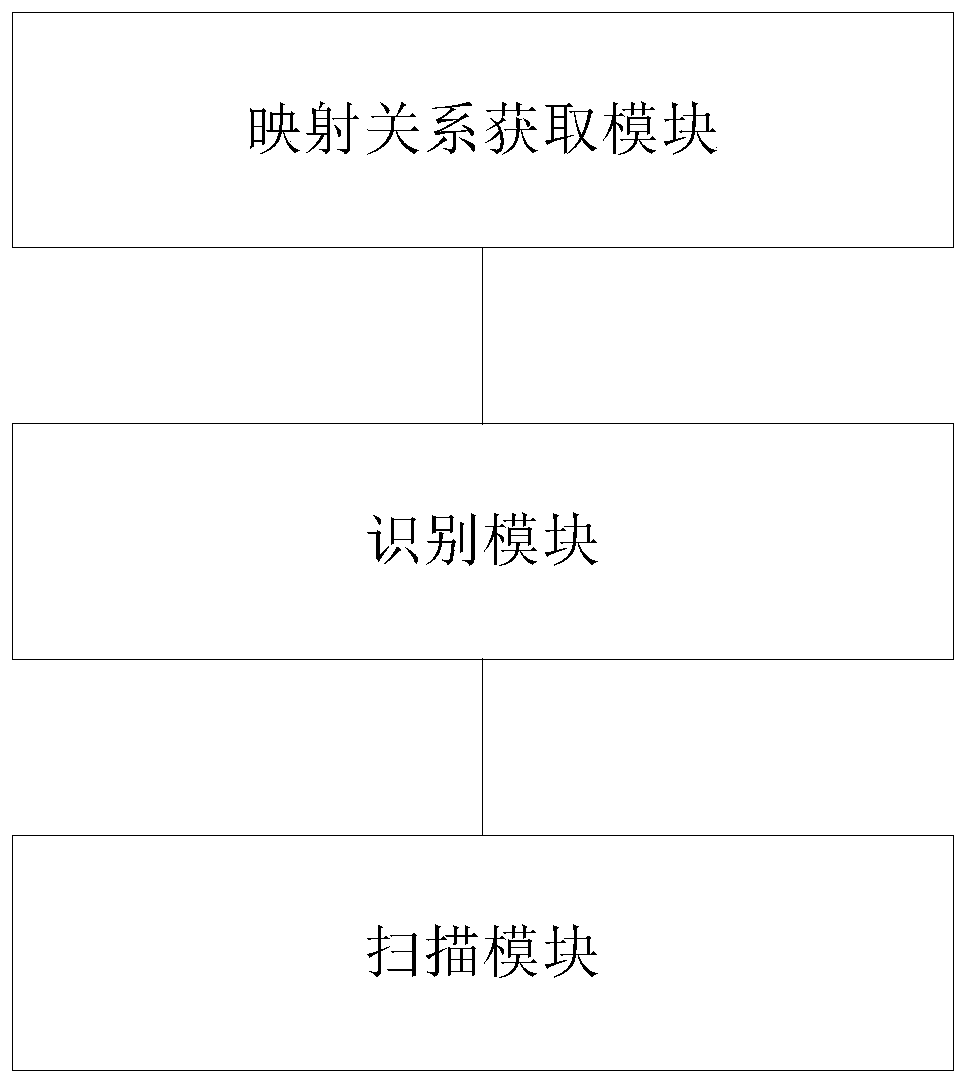

Code security scanning method and system

ActiveCN110619215AImprove accuracyImprove reliabilityPlatform integrity maintainanceCode compilationSource code

The invention discloses a code security scanning method and system, and the method comprises the steps: obtaining a mapping relation between a source code and a dynamic code through the conversion from the source code to the dynamic code; identifying a dynamic code; and scanning the source code and the dynamic code to obtain a scanning result. The system comprises a mapping relation acquisition module, an identification module and a scanning module. According to the method, on the basis of scanning the source code, the scanning step of the dynamic code is added, so that the code security scanning accuracy and reliability can be greatly improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

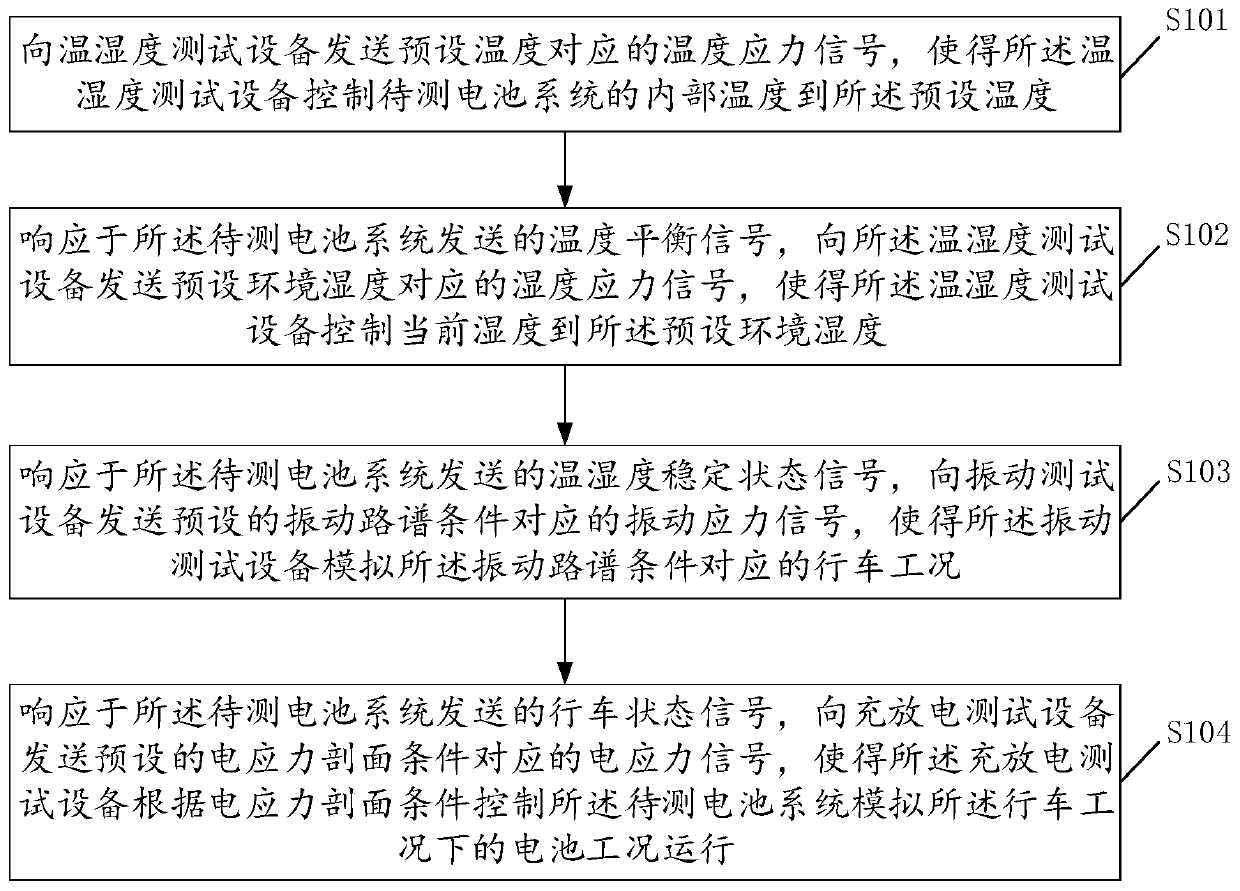

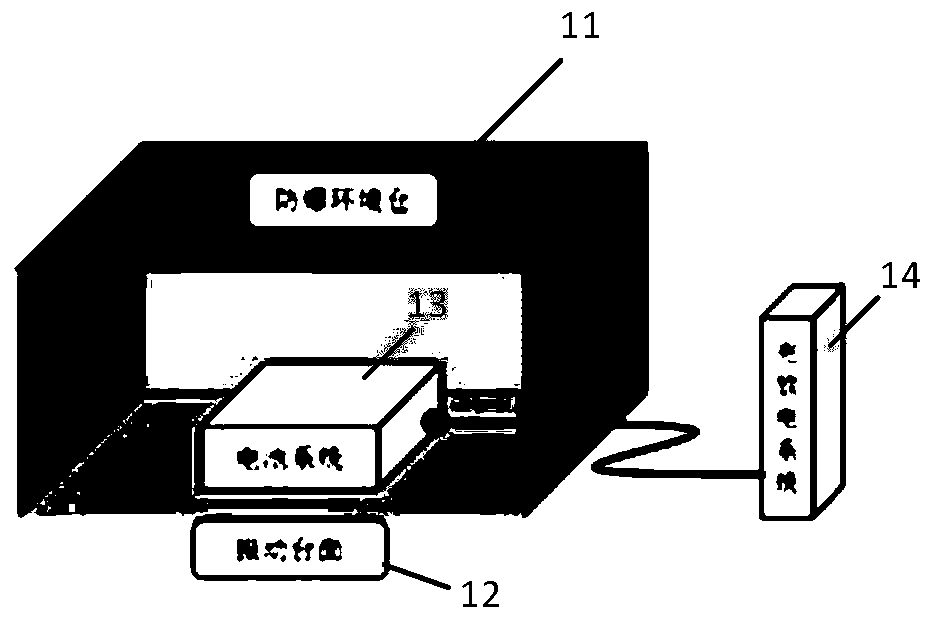

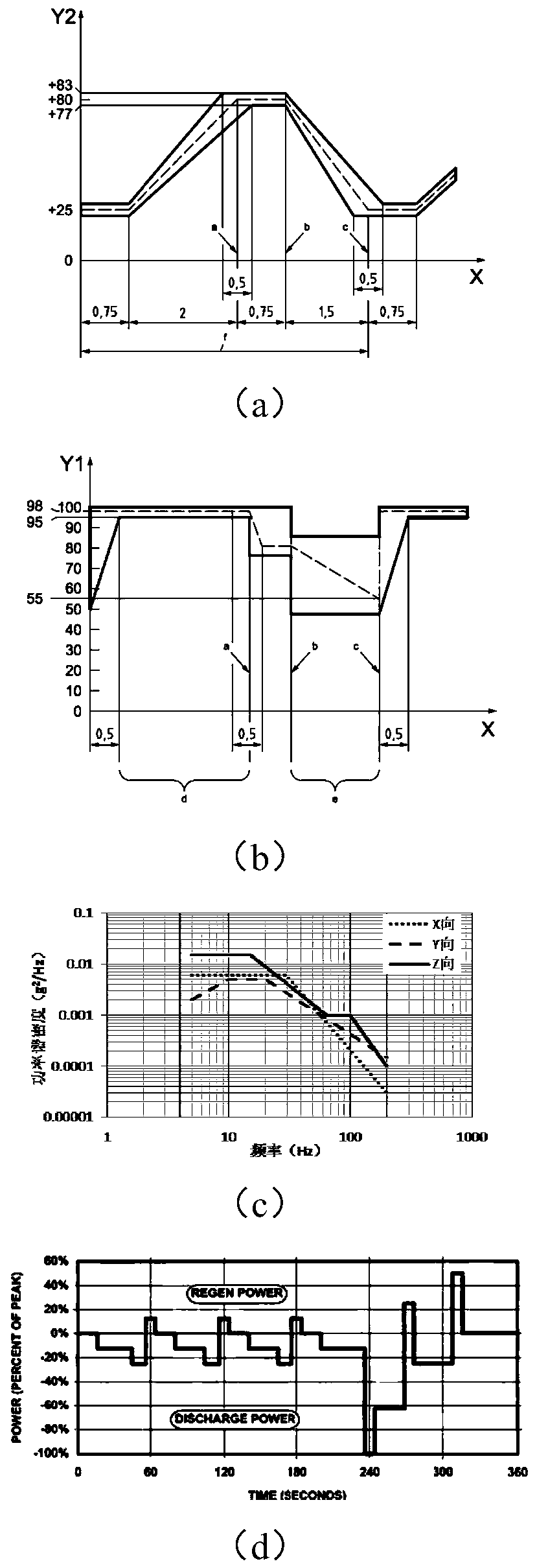

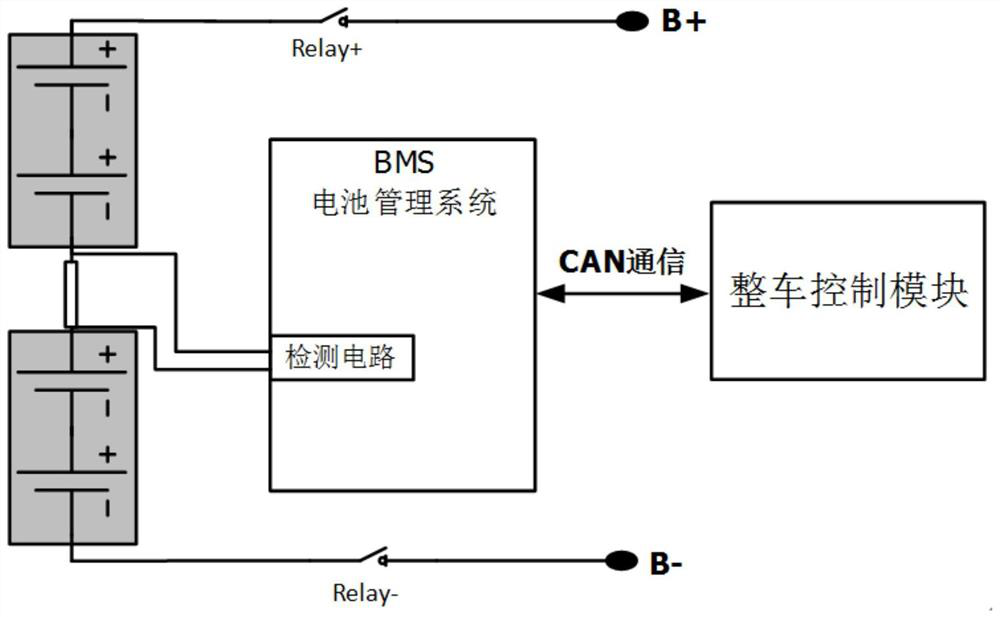

Battery system detection method and device, terminal equipment and storage medium

ActiveCN111060826AReflect real featuresSolve the problem of incomplete assessmentElectrical testingVibration testingTest batteryElectrical battery

The invention discloses a battery system detection method and device, terminal equipment and a storage medium. The method comprises the steps: transmitting a temperature stress signal corresponding tothe preset temperature to temperature and humidity test equipment, and enabling the temperature and humidity test equipment to control the internal temperature of a to-be-tested battery system to reach the preset temperature; responding to the temperature and humidity stable state signal transmitted by the to-be-tested battery system and sending a vibration stress signal corresponding to the preset vibration road spectrum condition to vibration test equipment so that the vibration test equipment simulates a driving condition corresponding to the vibration road spectrum condition; responding to the driving state signal transmitted by the to-be-tested battery system and sending an electric stress signal corresponding to the preset electric stress profile condition to charging and discharging test equipment so that the charging and discharging test equipment controls the to-be-tested battery system to simulate the battery working condition operation under the driving working condition. The problem that the battery system is not comprehensively evaluated under a single stress condition can be effectively solved, and the real characteristics of the battery system can be accurately andcomprehensively reflected.

Owner:广州广电计量检测(上海)有限公司 +1

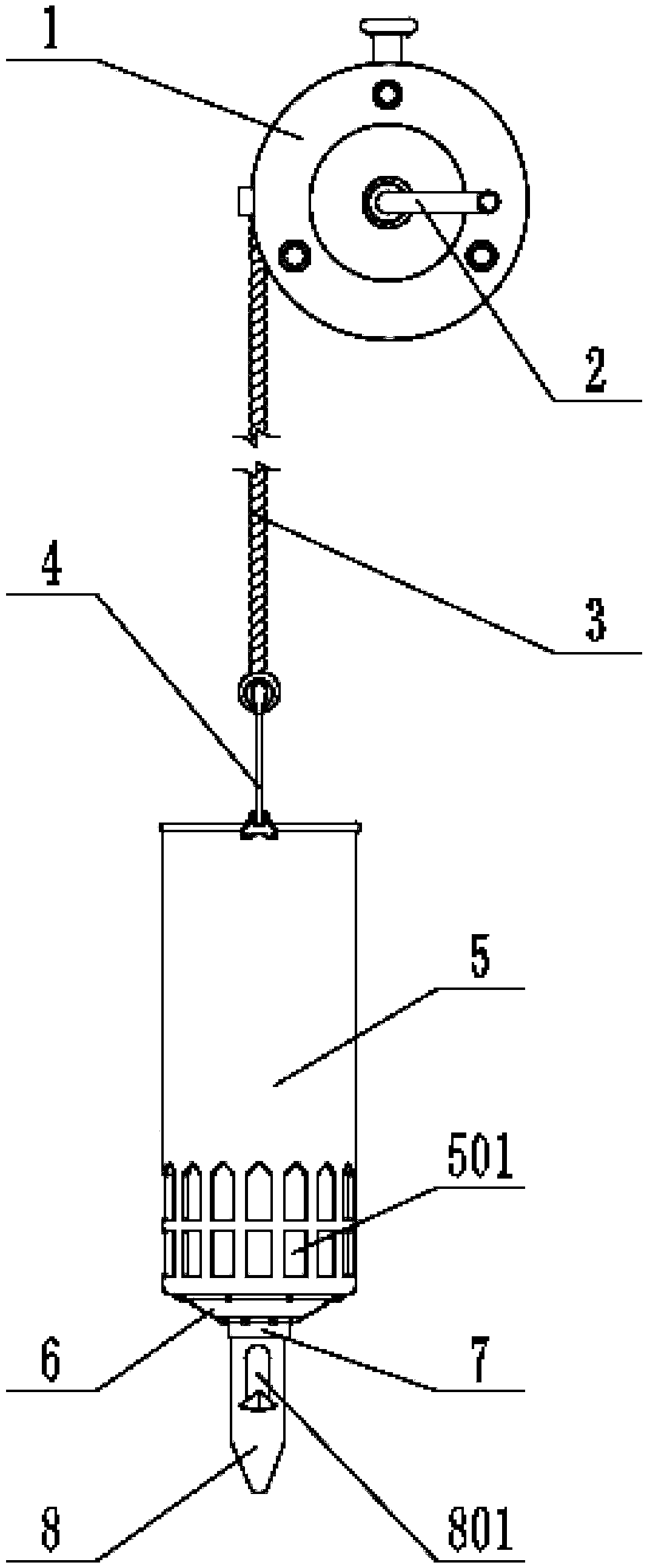

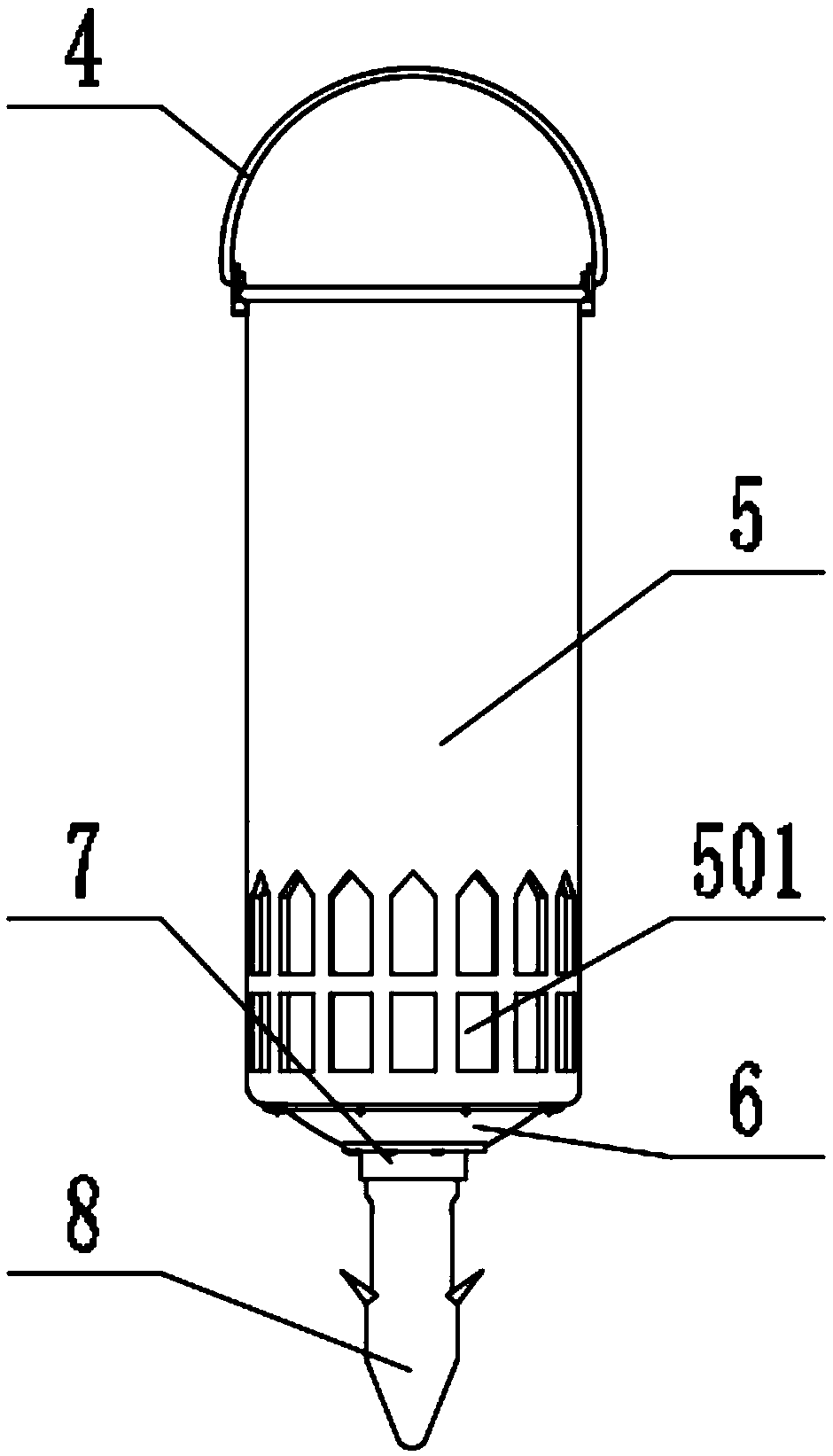

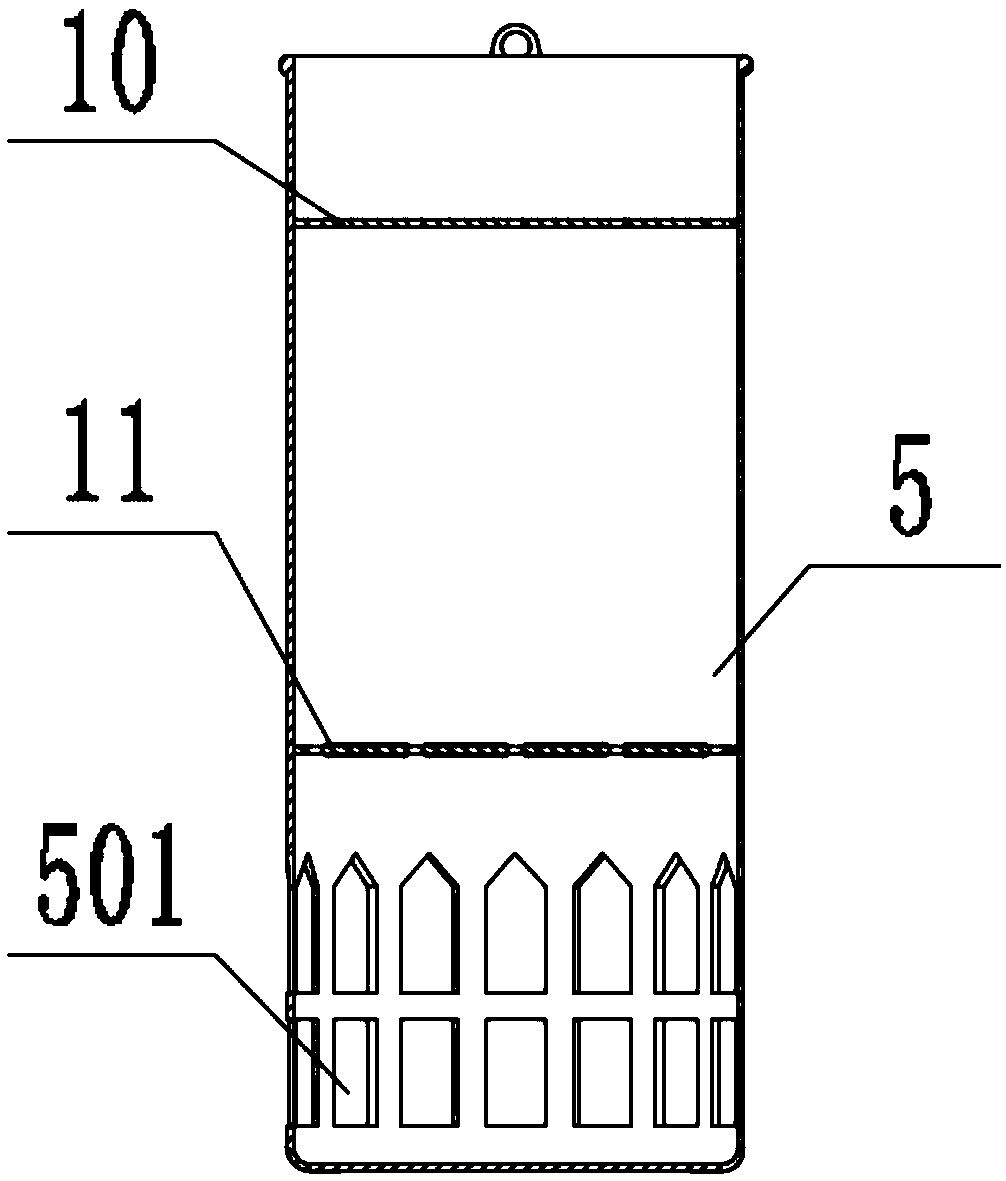

Sampling device for detecting water resources

InactiveCN108731983AConducive to collection operationsEasy to collectWithdrawing sample devicesWater resourcesEngineering

The invention provides a sampling device for detecting water resources. The sampling device comprises a test tube fixing hole and a rubber fixing ring, wherein a rotary handle is mounted on a front end face of a wire reeling device; the rotary handle is in rotary connection with an outer end face of the wire reeling device; the wire reeling device is connected with a lifting handle through a pulling rope; the lifting handle is of a circular-arc strip-shaped structure; two ends of the bottom of the lifting handle are mounted on a top end face of a collection bucket; a counter weight block is mounted at the bottom of the collection bucket; the top of a connection block is mounted on a circular-arc end face of the bottom of the counter weight block through a screw; two silt collection hole parts formed in a silt collection cone are of chamfer structures; the silt collection cone is located at the bottom of the collection bucket; water body sample collection is easy to carry out on a riverat a relatively deep part and a water well through the device, people do not need to slide to the water surface and can immediately carry out collection work on a water body sample at a part which isa relatively far away from the height of the water surface, so that the sample collection work is more convenient.

Owner:青海汇君检测技术有限公司

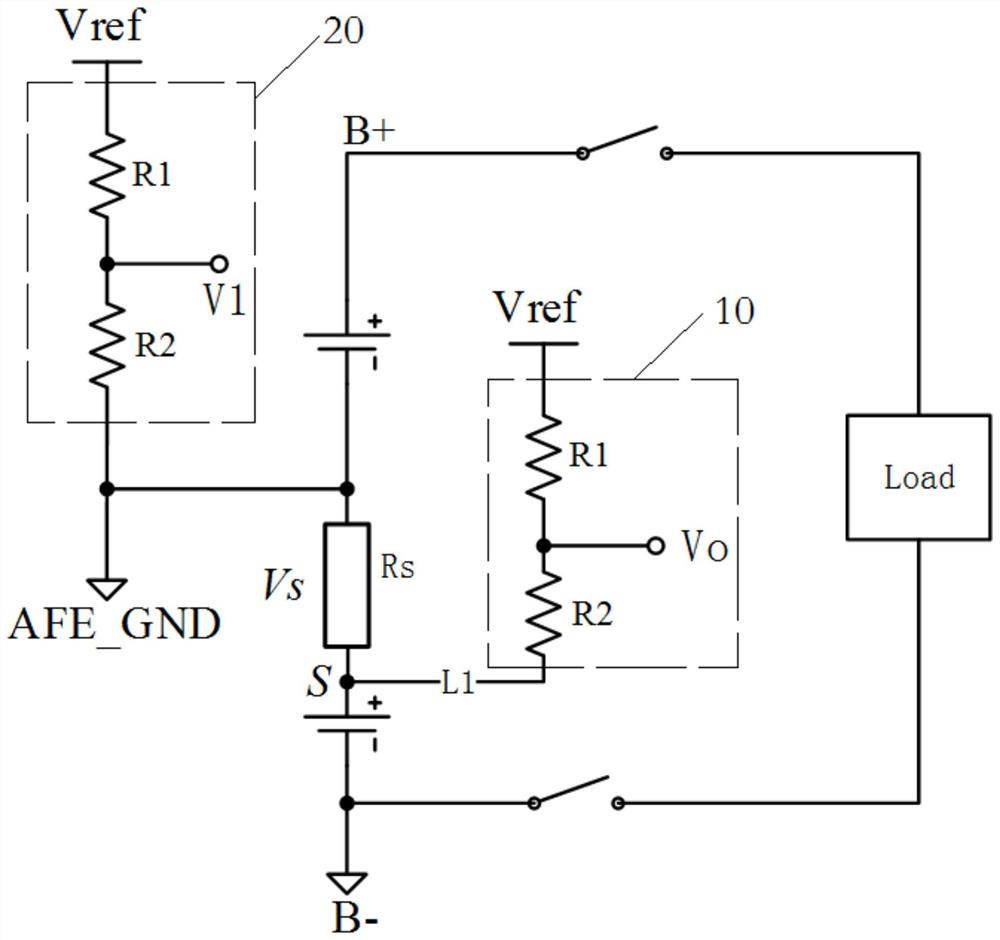

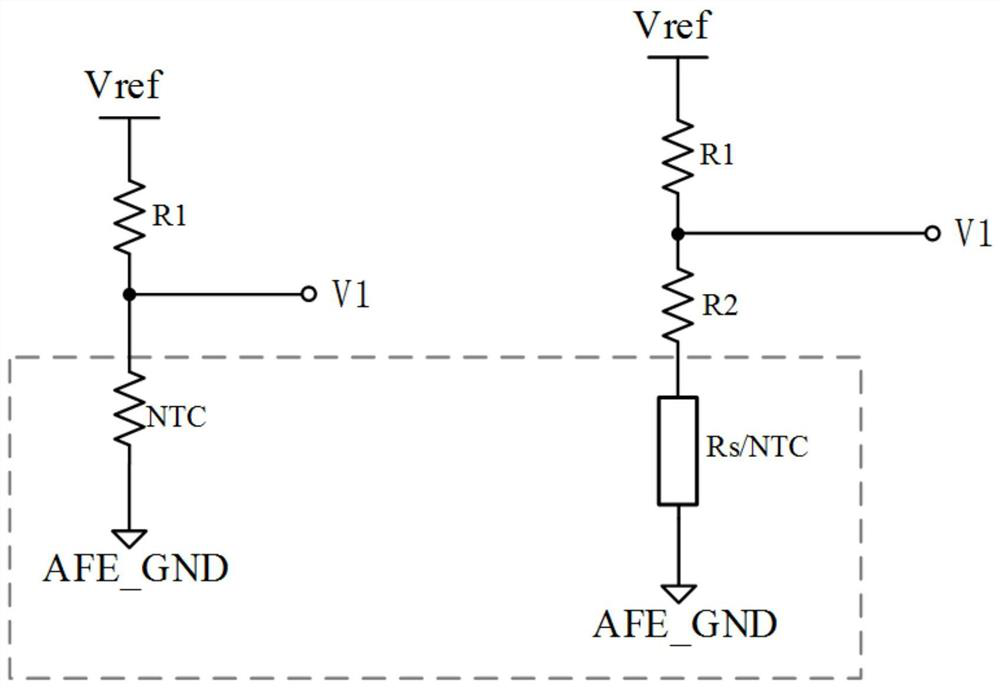

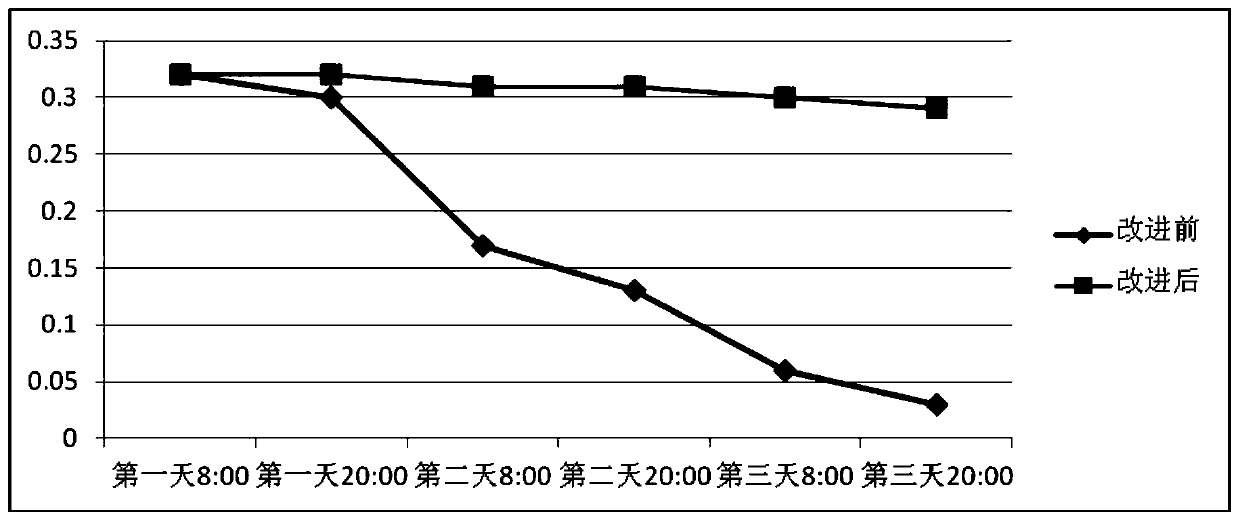

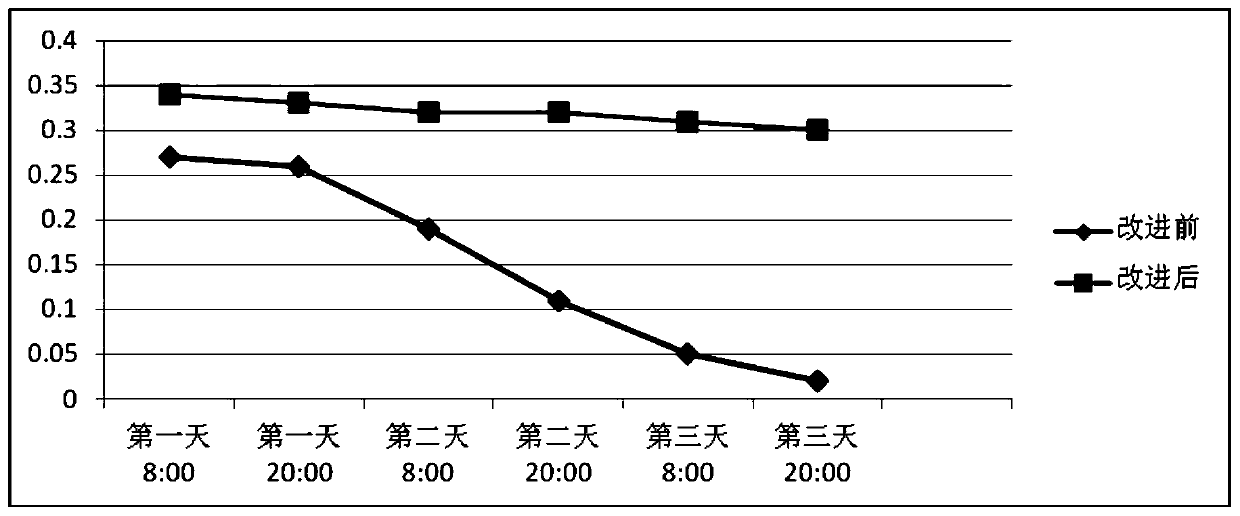

Detection circuit, detection system and detection method

PendingCN113960500AImplement connectivity diagnosticsEnsure safetyResistance/reactance/impedenceElectric connection testingElectric-vehicle batteryElectrical battery

The invention discloses a detection circuit, a detection system and a detection method, the circuit comprises a management system, a first bias circuit and a second bias circuit, one end of the first bias circuit is connected with one end of an element to be detected; one end of the second bias circuit is connected with the other end of the to-be-tested element and is grounded, and the other ends of the first bias circuit and the second bias circuit receive externally input bias voltage; the first biasing circuit comprises a first resistance voltage division circuit, and the second biasing circuit comprises a second resistance voltage division circuit; and the management system is used for collecting the first voltage in the first resistance voltage division circuit, the second voltage in the second resistance voltage division circuit and the current flowing through the element to be detected, and judging the state of the element to be detected. By implementing the invention, the voltage of the element to be detected can be tested, and the resistance is calculated in combination with the current, so that the state of the element to be detected can be judged according to the resistance. Therefore, the detection circuit can be applied to an electric vehicle battery system to realize connectivity diagnosis of a copper bar.

Owner:SUNWODA ELECTRONICS

Method for preparing blank solution in PT base value determination method

ActiveCN109828081ABlank determination is stableReduce the number of timesChemical analysis using titrationDistilled waterRoom temperature

The invention provides a method for preparing a blank solution in a PT base value determination method. The method comprises the following steps of: the step 1: adding 9500ml of a 99.9% methanol solution to a glass bottle, adding 400ml of distilled water to the methanol solution, adding 0.8ml of 0.5mol / L sodium hydroxide solution, and stirring the mixture for 8 hours at the first time to prepare amethanol solution of sodium hydroxide; the step 2: performing standing of the methanol solution of sodium hydroxide obtained in the step 1 in an open state at a room temperature; and the step 3: performing stirring of the methanol solution of sodium hydroxide for the second time, and employing a bottle cap to cover the methanol blank solution of sodium hydroxide for standby. The base value of thepolytetrahydrofuran prepared in the invention is employed to measure the blank solution to reduce the number of times of the measurement of the blank solution, improve the measurement accuracy of thePT base value and improve the finished product of the PT product.

Owner:SHAANXI SHANHUA COAL CHEM IND GRP

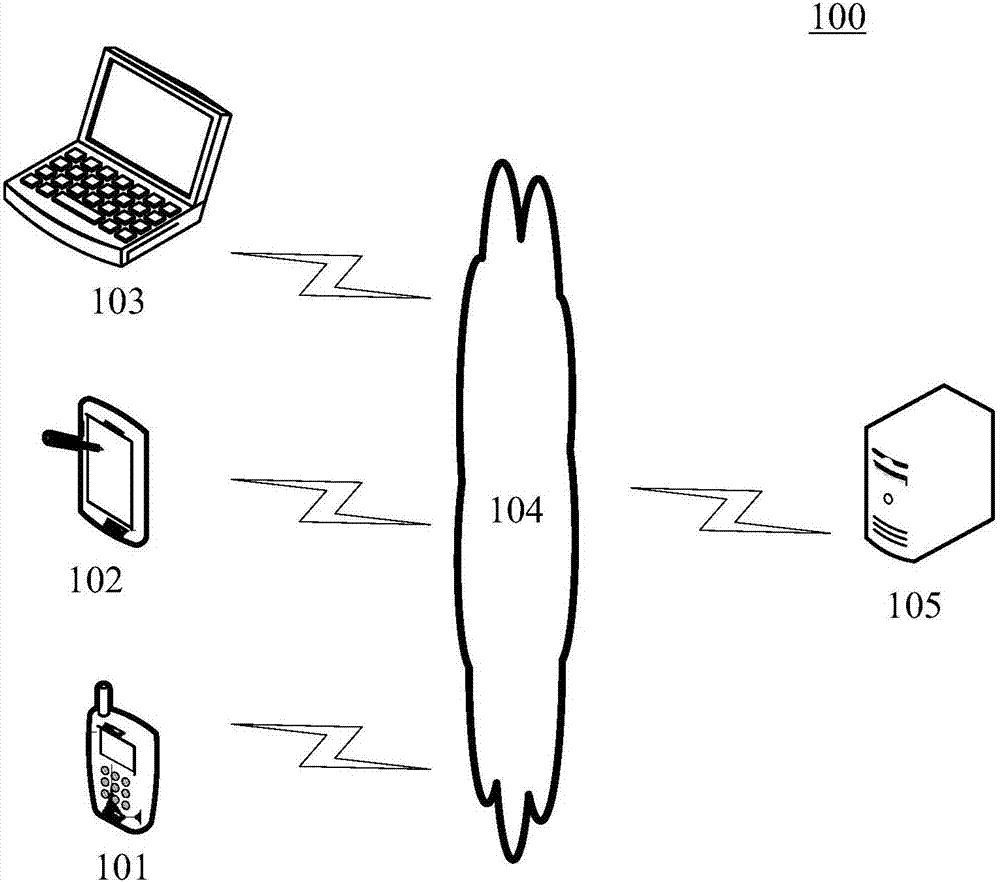

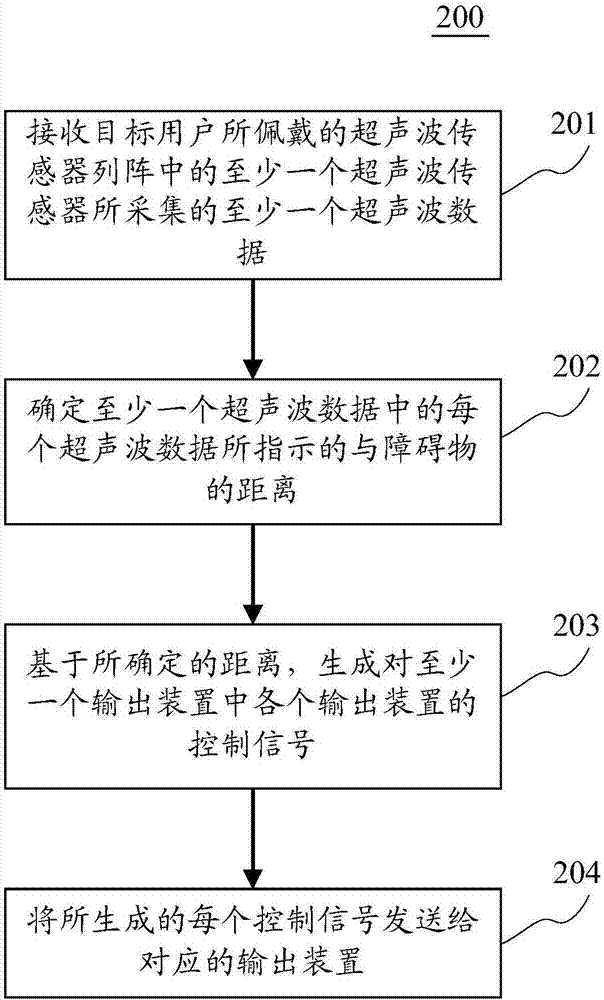

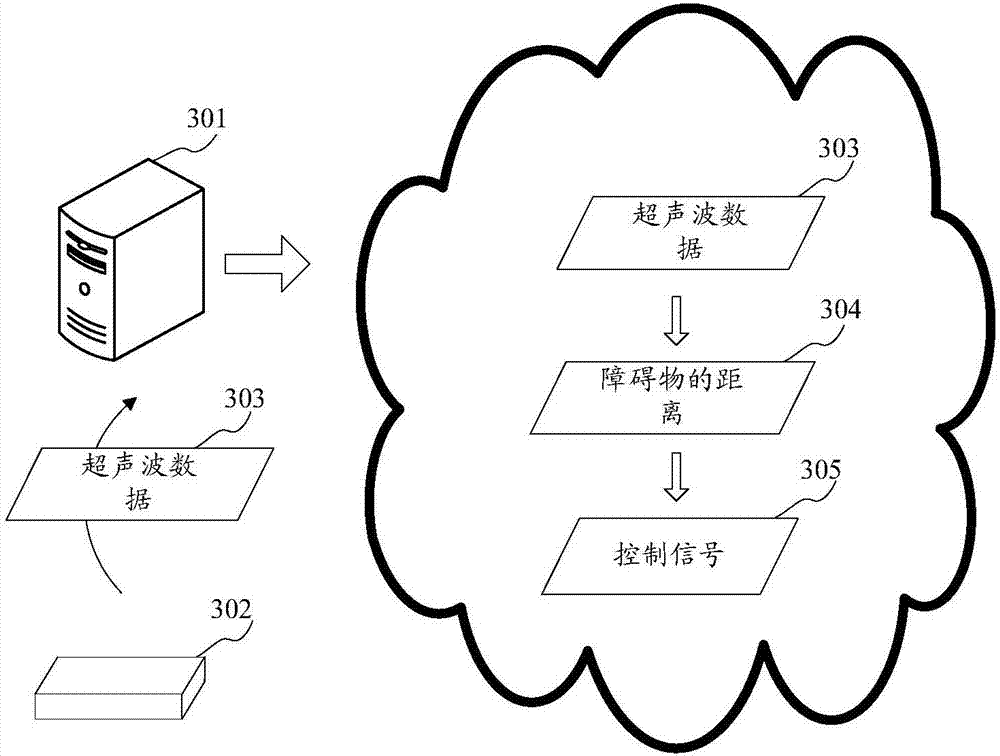

Obstacle detection method and device

The embodiment of the application discloses an obstacle detection method and a device. A specific embodiment mode of the method includes steps of receiving at least one ultrasound wave data collectedby at least one ultrasound sensor in an ultrasound sensor array worn by a target user; confirming the distance between an instructed matter of every ultrasound wave data in at least one ultrasound wave data and the obstacle; based on the confirmed distance, generating a control signal of every output device in at least one output device, wherein the output device comprises a vibrating motor; sending every generated control signal to corresponding output device. Through the distance between the instructed matter of every ultrasound wave data and the obstacle, a control signal is generated, andthe accuracy of the obstacle detection is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

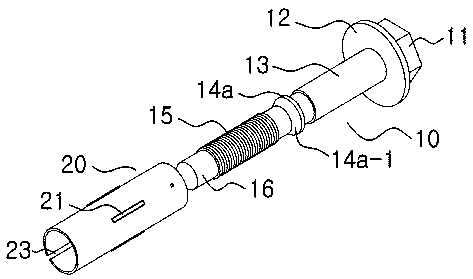

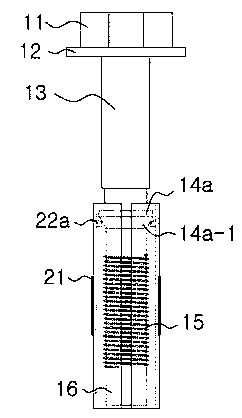

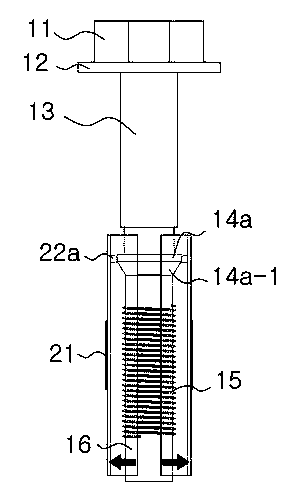

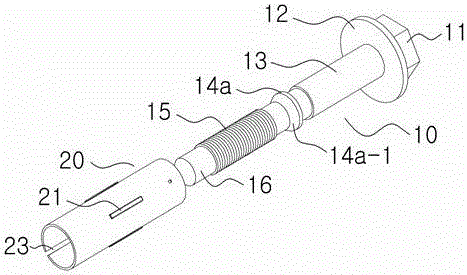

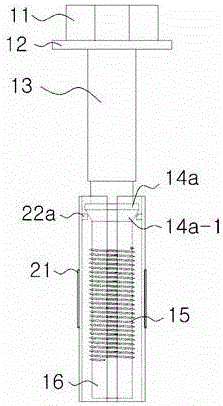

Insert bolt using bushing and manufacturing method of bushing

ActiveCN105090195APrevent disengagementMentioned accuracyScrewsDowelsStructural engineeringMechanical engineering

The invention relates to an insert bolt using a bushing and a manufacturing method of the bushing. In order to stably assemble the bolt, the bushing is clamped in a groove where the base metal bolt is connected, and the embedded bushing can play a role in guiding the connection position of the bolt, thus improving accuracy and stability. Besides, the bushing can be fixed on the base metal by using an outer side projection arranged on the outer side face of the bushing, and the bolt can be prevented from separating from the bushing by using an inner side projection arranged on the inner side face of the bushing.

Owner:GENERAL CO LTD

Insert bolt using core bushing and manufacturing method of core bushing

The invention relates to an insert bolt and a bushing manufacturing method using a bushing. In order to assemble the bolts stably, the bushing is clamped in the groove connected by the base material bolt, and the embedded bushing can play a role in guiding the bolt connection. The role of position, thus referring to accuracy and stability. In addition, the bushing can be fixed to the base material by the outer protrusions provided on the outer side of the bushing, and the bolts can be prevented from coming out of the bushing by the inner protrusions provided on the inner side of the bushing.

Owner:GENERAL CO LTD

Pendulum for Micro Rotor Dynamic Balancing Machine

ActiveCN103389182BHigh sensitivityLarge amplitudeStatic/dynamic balance measurementBalancing machineDynamic balance

The invention discloses a swing frame for a mini-sized rotor dynamic balancing machine. A machine frame of the swing frame is a rigidity guide frame which is fixedly arranged; the machine frame is matched with supporting blocks in a guiding mode at a horizontally swinging linear direction of the supporting blocks through a guide mechanism; the guide mechanism comprises the machine frame, guide rods and guide channels; the guide rods and the guide channels are correspondingly formed on the supporting blocks and extend along the swing direction of the supporting blocks; the number of the guide blocks is at least two; the guide rods are separately arranged by two guide rods; the guide channels and the guide rods are arranged in a one-to-one correspondence mode; damping devices are damping units which are arranged at two back-to-back sides of the swing direction of the supporting blocks in an elastic damping check mode. Accordingly, the existing machine frame which has an elastic supporting function is replaced by the rigidity machine frame, the frame self-rigidity influence to guide swing of supporting blocks is reduced through guide movement of the supporting blocks on the machine frame, and the sensitivity of the integral swing frame during the processing of measuring the mini-sized rotor dynamic imbalance performance is improved.

Owner:HENAN UNIV OF SCI & TECH

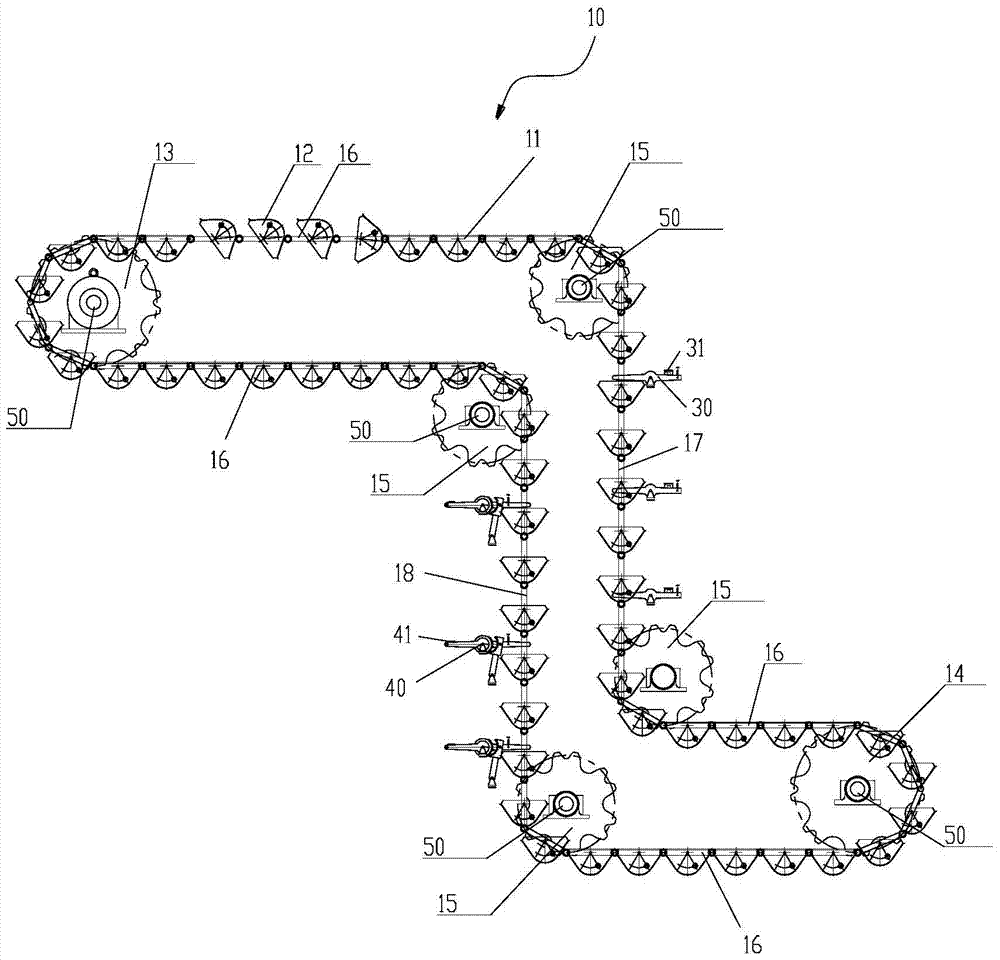

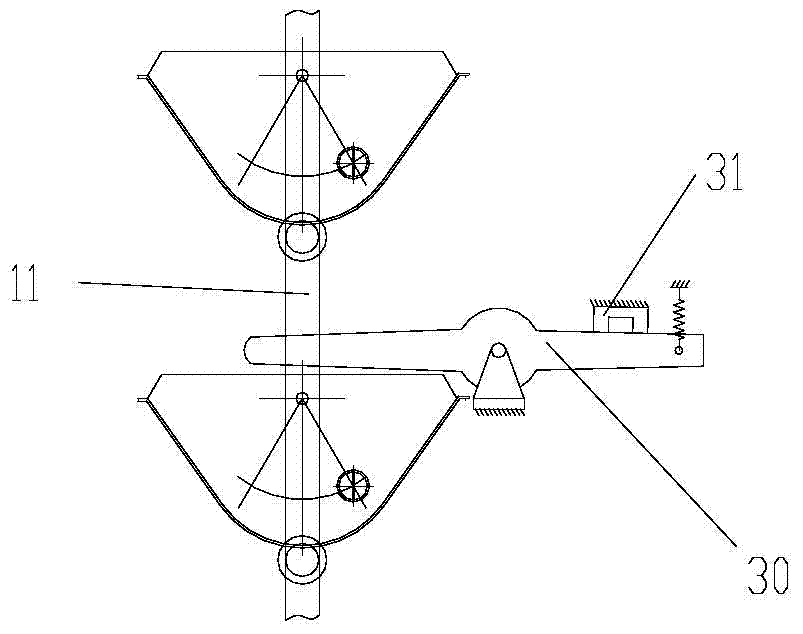

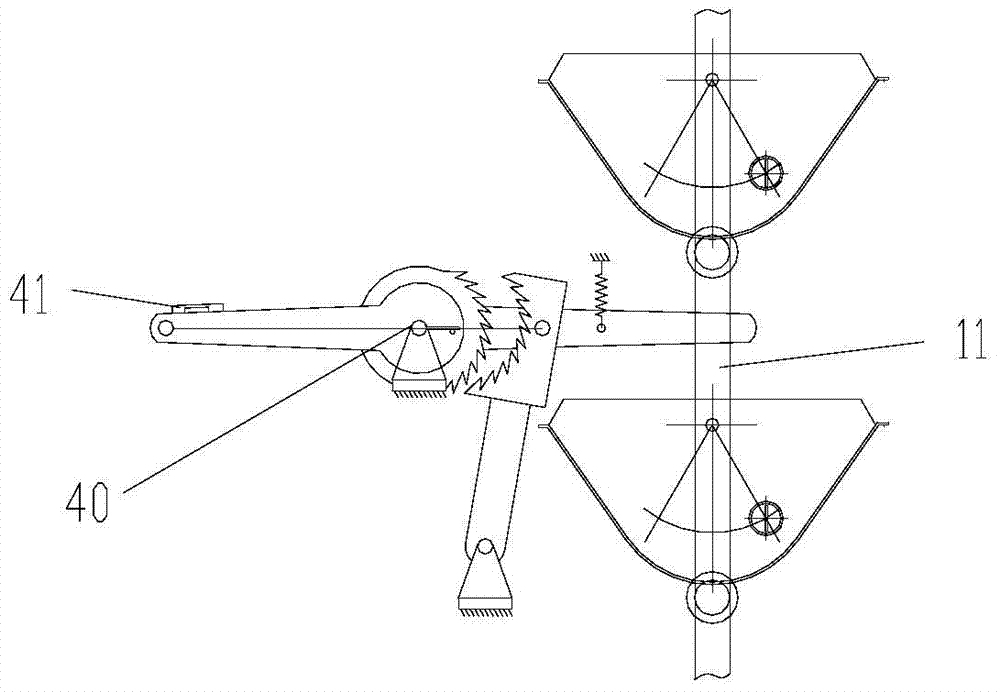

Chain conveyor and chain breaking protection method

ActiveCN104192534BAvoid pullingPrevent fallingControl devices for conveyorsChain scissionChain conveyor

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

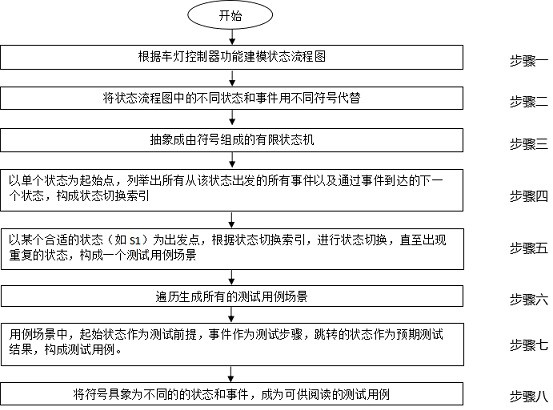

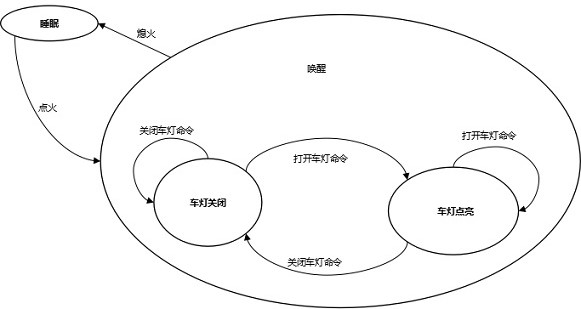

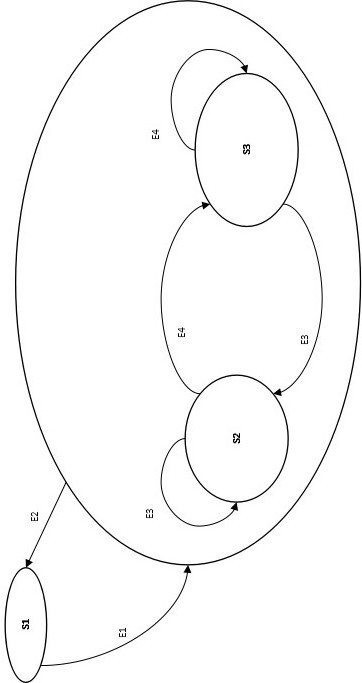

Test case automatic generation method for vehicle lamp controller based on state machine

PendingCN112286793AImprove efficiencySave human effortSoftware testing/debuggingTest requirementsManual handling

The invention aims to provide a test case automatic generation method for a vehicle lamp controller based on a state machine, which comprises the following steps of: marking all states and trigger events of the vehicle lamp controller one by one by using symbols so as to abstract system requirements of the vehicle lamp controller into a finite automatic state machine model; according to the model,automatically generating a test case of the vehicle lamp controller by a tool; abstracting a state flow chart of the vehicle lamp controller into a state machine model, automatically generating all test cases by a tool, the efficiency is high so that manpower is saved, errors are not likely to happen, and an effective basis is provided for statistics of the coverage rate of test requirements; thedefect that in the prior art, the process is large in workload and tedious is overcome, and careless omission during manual operation is avoided.

Owner:MAGNETI MARELLI AUTOMOTIVE COMPONENTS WUHU

A method of detecting the life of a fuse by determining the activation energy of the melt

The invention discloses a method for assessing service lives of fuses by determining activation energy of melts. The method comprises the steps that accelerating aging test of different accelerated stresses is conducted on a plurality of sets of fuses, metal electromigration service lives of the melts under different temperatures are obtained according to a plurality of sets of test data, the activation energy of the melts is calculated in the curve fitting method, parameters of service life assessing models of the fuses are determined, and therefore the service lives of the melts under different conditions can be calculated, and the activation energy of the melts is determined in a test method to assess the service lives of the fuses. Compared with empirical data adoption in the prior art, the method can improve accuracy of assessment of the service lives of the fuses.

Owner:SUZHOU NUCLEAR POWER RES INST +1

A foldable automatic charging mechanical arm and an electric vehicle equipped with the mechanical arm

InactiveCN105691228BRealize automatic chargingRealize automatic power offVehicle connectorsCharging stationsElectric vehicleMechanical engineering

The invention relates to a folding automatic charging mechanical arm and an electric vehicle vehicleried with the mechanical arm. The mechanical arm is arranged at the bottom of the electric vehicle, and charging of the electric vehicle is achieved by plugging the mechanical arm into a socket. The mechanical arm comprises a swing arm fixing plate, a head joint, a connection plate, a parallel joint unit, a plug and a camera, wherein one end of the swing arm fixing plate is fixed to the bottom of the electric vehicle; one end of the head joint is connected with the other end of the swing arm fixing plate so that the mechanical arm can rotate around the head joint; the connection plate is an inverted U-shaped strip slot, and is connected with the head joint; the parallel joint unit is connected with the connection plate in a sliding mode; the parallel joint unit is located in the connection plate when the electric vehicle is not charged, and extends out of the connection plate and rotates around parallel joints when the electric vehicle needs to be charged; the plug is mounted at the tail end of the parallel joint unit; and the camera is mounted on one side face of the plug. Compared with the prior art, automatic charging is realized, a charging device is small in size, and using is convenient. The vehicle-mounted automatic charging mechanical arm fills up the blank in China and is of great significance on promoting the technological development of electric vehicles.

Owner:SHANGHAI INT AUTOMOBILE CITY GRP CO LTD +1

A data labeling method and device based on a self-learning algorithm

ActiveCN109830230BSave labeling timeImprove labeling efficiencyNatural language data processingSpeech recognitionAlgorithmSpeech sound

Owner:深圳平安综合金融服务有限公司

Determination method of high voltage direct current converter commutation overlap angle

InactiveCN101834437BSimple designImprove performanceDc circuit to reduce harmonics/ripplesWork periodHigh-voltage direct current

The invention discloses a determination method of a high voltage direct current converter commutation overlap angle, aiming to solve the problem that a traditional method for calculating a commutation overlap angle can not take nonideal factors including background harmonics into consider to cause poor design performance of a wave filter. The method comprises the following steps of dividing the working period of a converter into six commutation sections and six non-commutation sections; establishing a differential equation to each commutation section by considering factors such as background harmonic interference, asymmetric fundamental voltage, asymmetric converter trigger angle distances, commutation impedance deviation and the like; and accurately calculating the commutation overlap angle. The invention efficiently enhances the calculation efficiency when ensuring the accuracy and can enhance the design quality of an alternating current converter.

Owner:ZHEJIANG UNIV

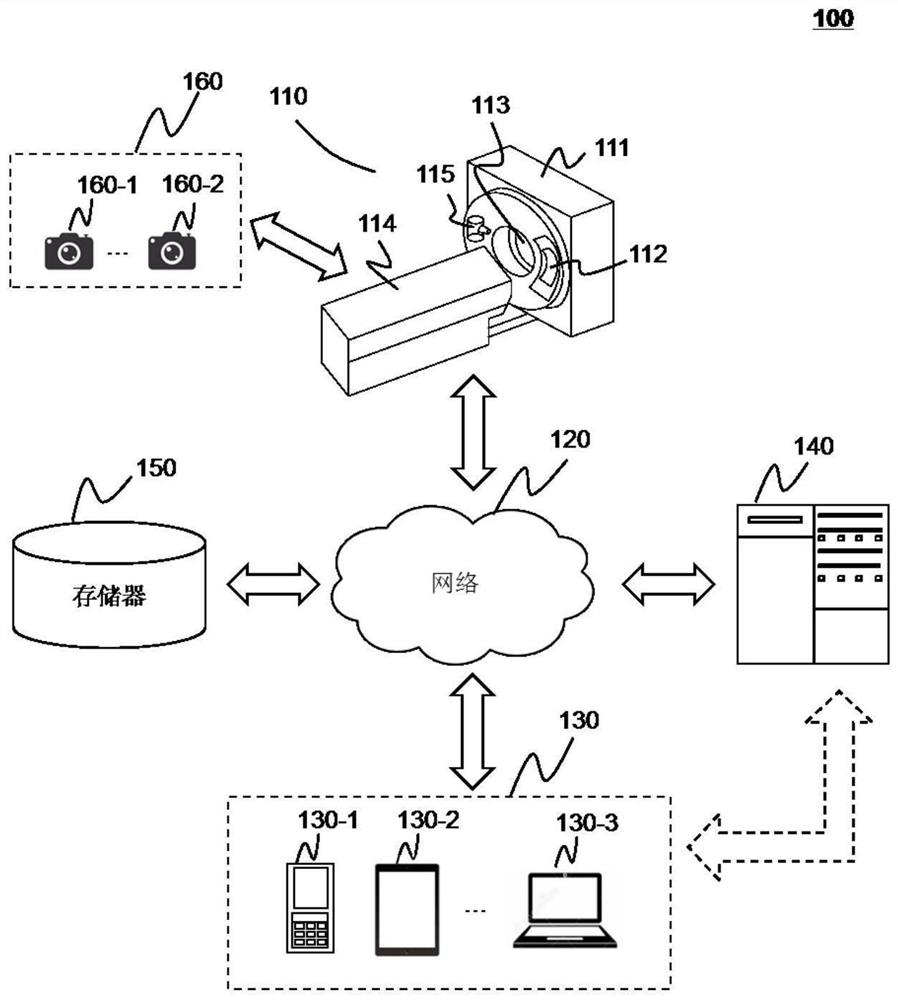

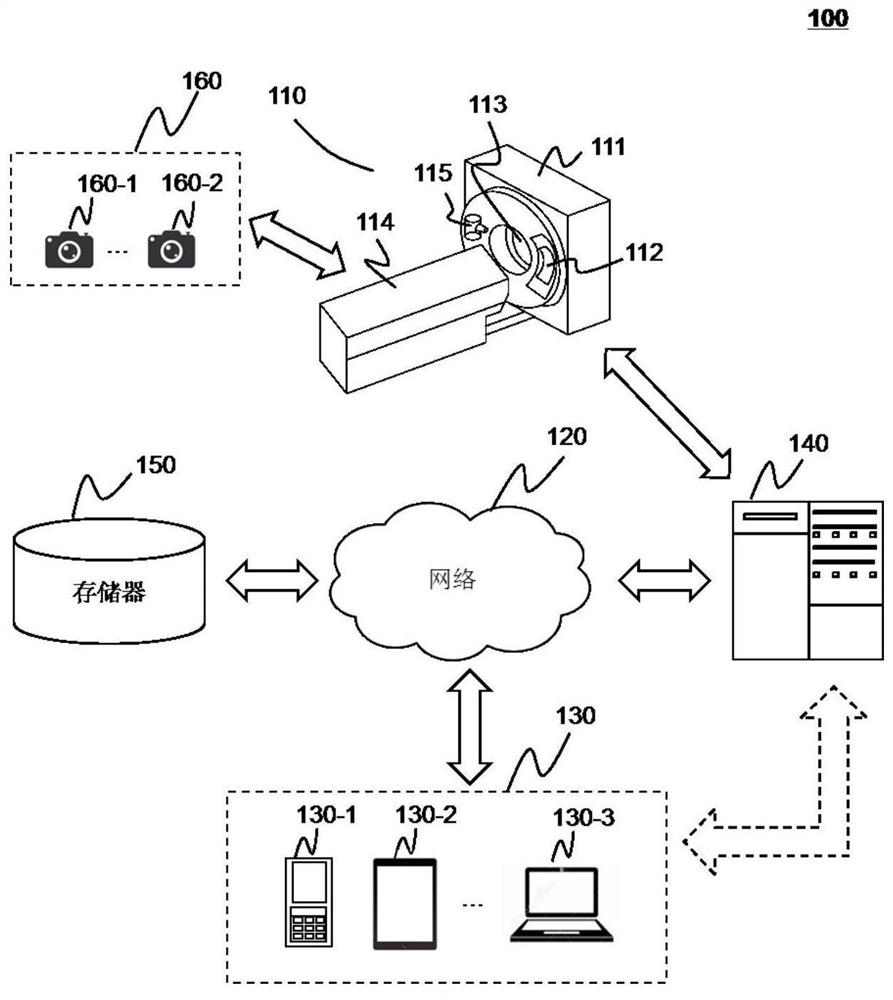

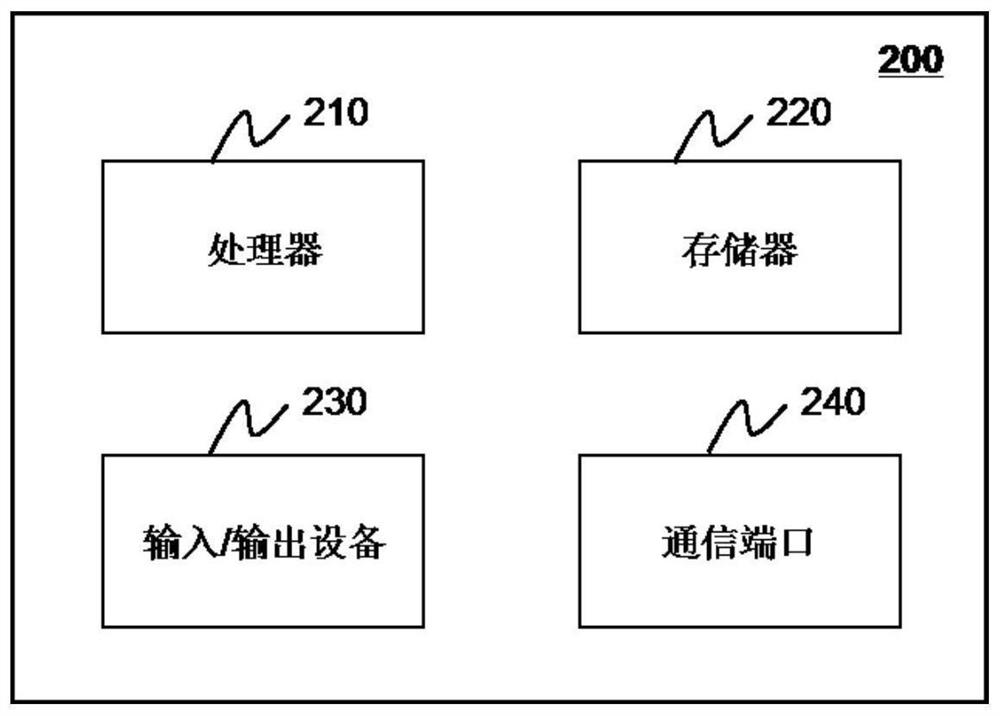

Automated imaging method and system

ActiveCN107992817BSave operating timeImprove diagnostic efficiencyMedical simulationImage enhancementRadiologyComputer vision

The invention discloses an automatic imaging method and system. The method includes: acquiring image data of a target object placed on a scanning bed; determining first position information of the target object by a processor based on the image data; determining by the processor based on the image data second location information related to a scanning area of the target object; and scanning the target object by an imaging device based on the first location information and the second location information. The automatic imaging method reduces the user's operation time before clinical scanning, and can also avoid the user's mistakes in manual operation, thereby improving the efficiency and accuracy of clinical examination.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

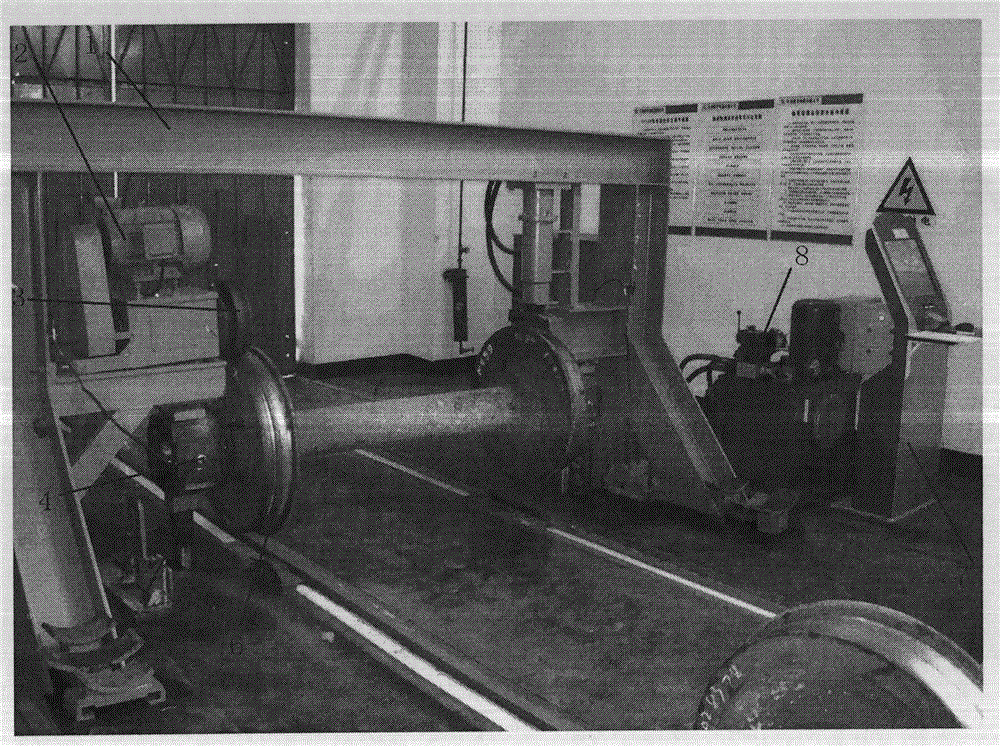

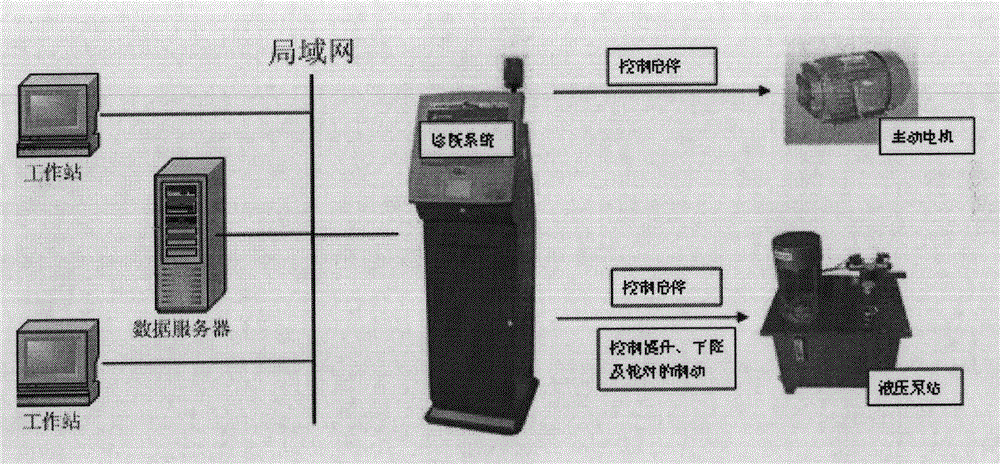

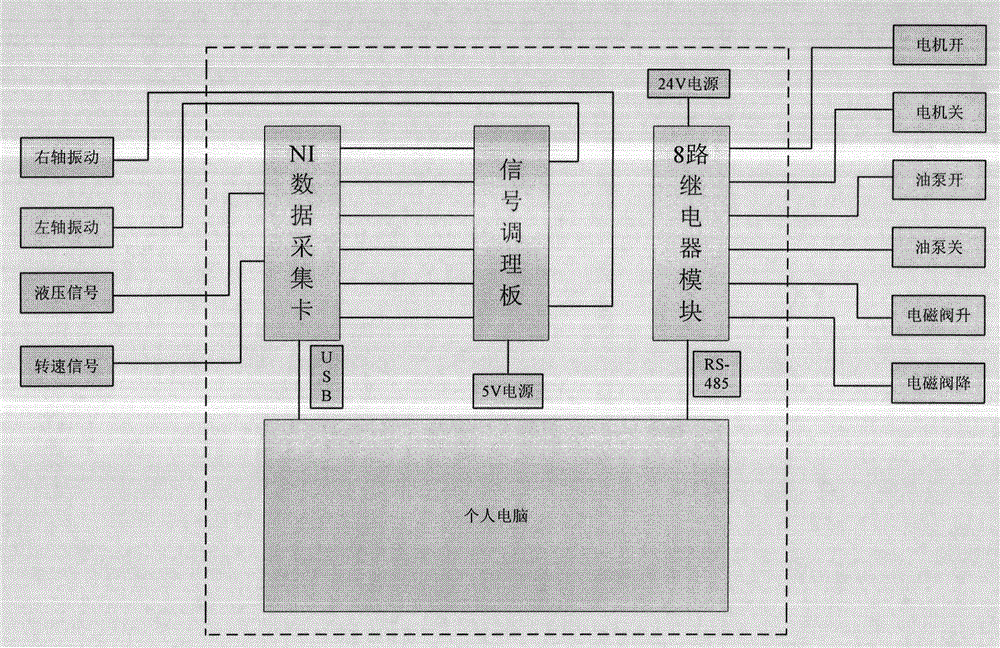

Intelligent detection system of special metallurgical vehicle wheel set bearings

ActiveCN102589881BEasy maintenanceEasy to manageMachine bearings testingVibration accelerationDisplay device

The invention relates to an intelligent detection system of special metallurgical vehicle wheel set bearings. The system comprises a rotating platform, a hydraulic pump, a touch display, a personal computer, a computer cabinet, a signal switchboard, a signal acquisition card, an 8-path relay output module, a vibration sensor, a rotating speed sensor, a hydraulic sensor, connecting wires for each part, a signal communication module, a driving control module, a data acquisition and processing module and a data warning and report generating module. A wheel set is placed on the rotating platform, the computer controls the wheel set to be lifted to a designated position, vibration acceleration sensors are placed at horizontal positions of bearing at both sides of the wheel set, and belt pulleys are driven by a motor to rub with the wheel set. When the rotating speed keeps constant, the wheels stay in the uniform rotation state, vibration signals are started to be collected, test data is stored after collection, and the wheel set is put back to the original position. The software can analyze whether the wheel set has bearing faults through the rotating speed, the current bearing model and the vibration signal. With the detection system, the accuracy rate and the real-time performance are effectively increased, the detection time is reduced, and the detection cost is reduced.

Owner:马鞍山马钢华阳设备诊断工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com