Chain conveyor and chain breaking protection method

A broken chain protection, conveyor technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problem of falling down, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

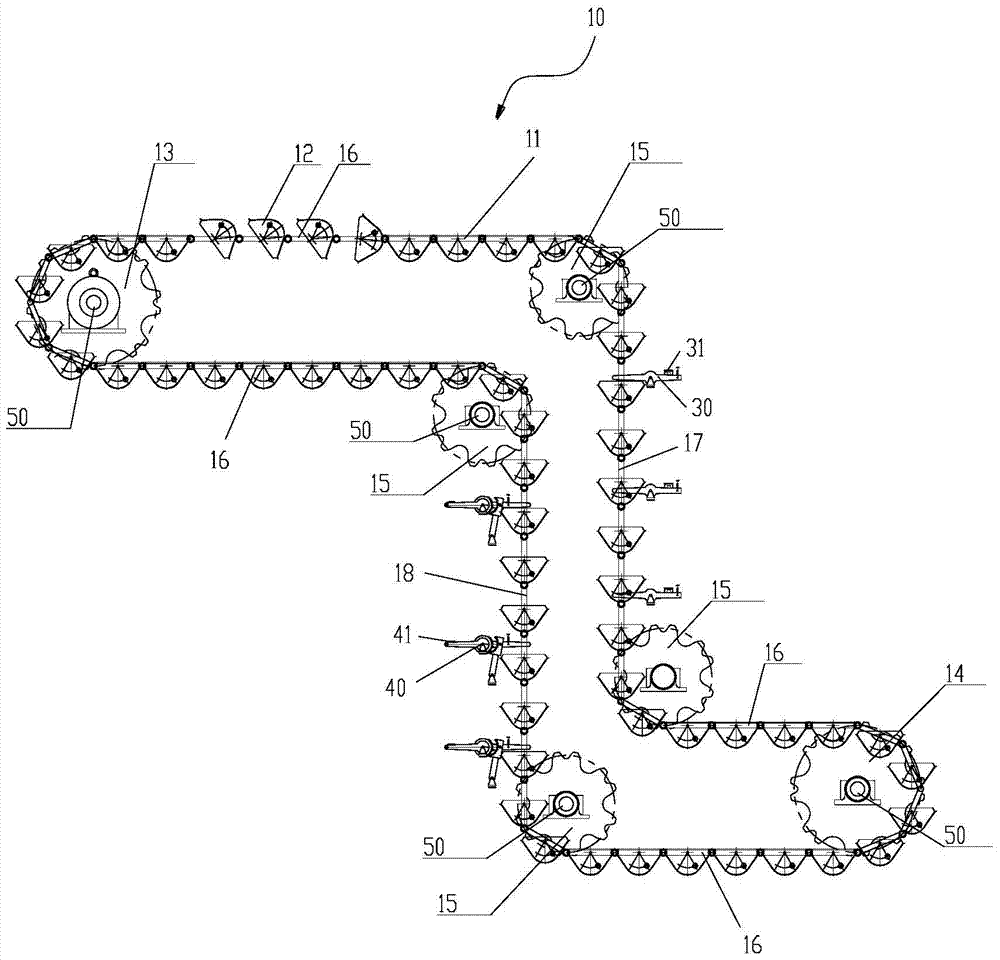

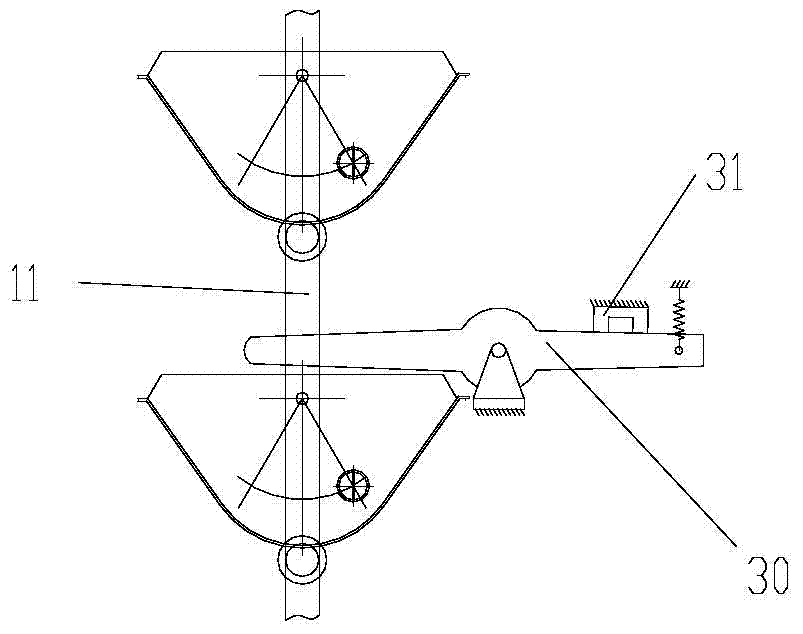

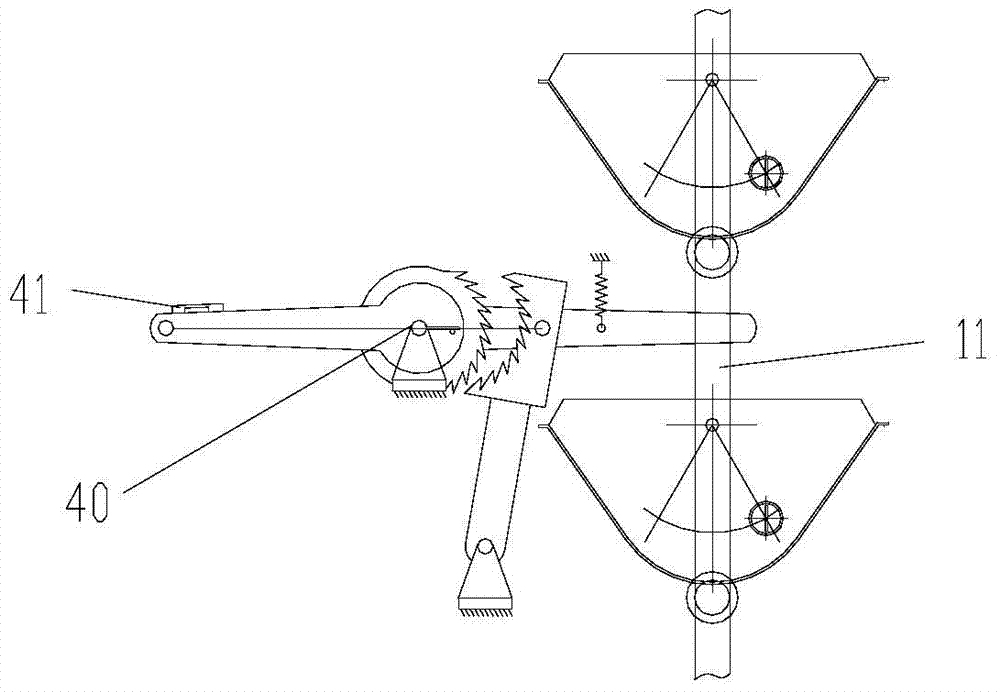

[0022] figure 1 A chain conveyor 10 (hereinafter referred to as conveyor 10 ) according to the invention is schematically shown. Such as figure 1 As shown, the conveyor 10 includes a chain 11 and a wheel set including a plurality of wheels for supporting and driving the chain 11 . A hopper 12 is movably arranged on each link of the chain 11, so as to load materials into the hopper 12 and realize automatic unloading of materials. These materials can be, for example, activated carbon. In order to convey materials between positions of different heights, the chain 11 is generally arranged in a "Z" shape in the vertical direction, which can be realized by properly arranging the wheels. Such as figure 1 As shown, chains 11 are connected end to end to form a closed loop. The drive wheel 13 is arranged at the first position on the upper part, the steering wheel 14 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com