Synchronous assembly

A technology of synchronous components and synchronous rings, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve problems such as vibration and uneven operation of three-cylinder engines, and achieve high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

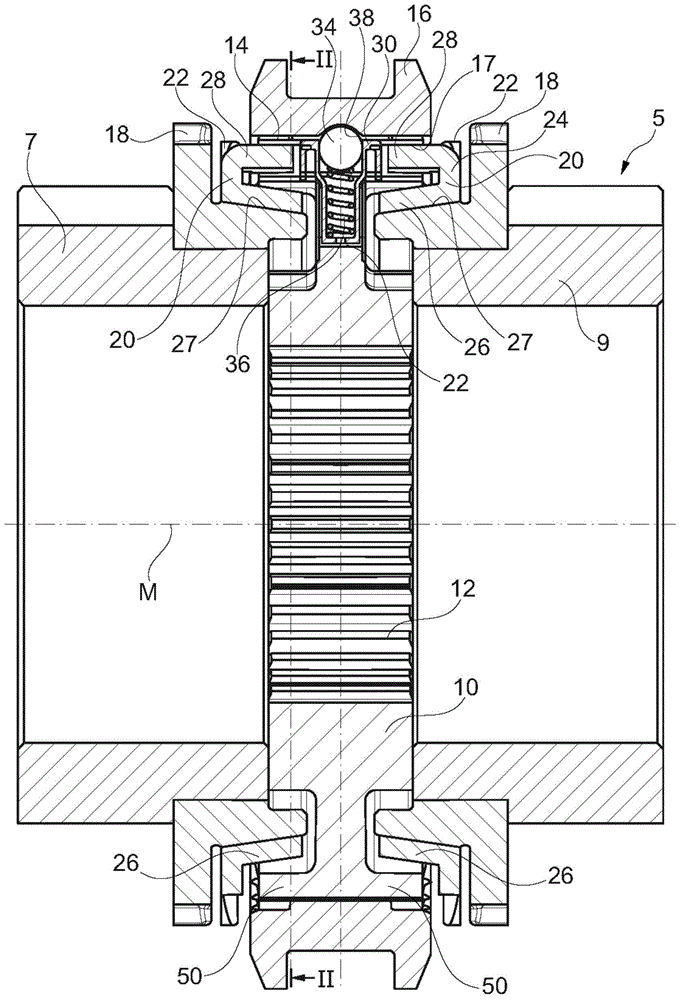

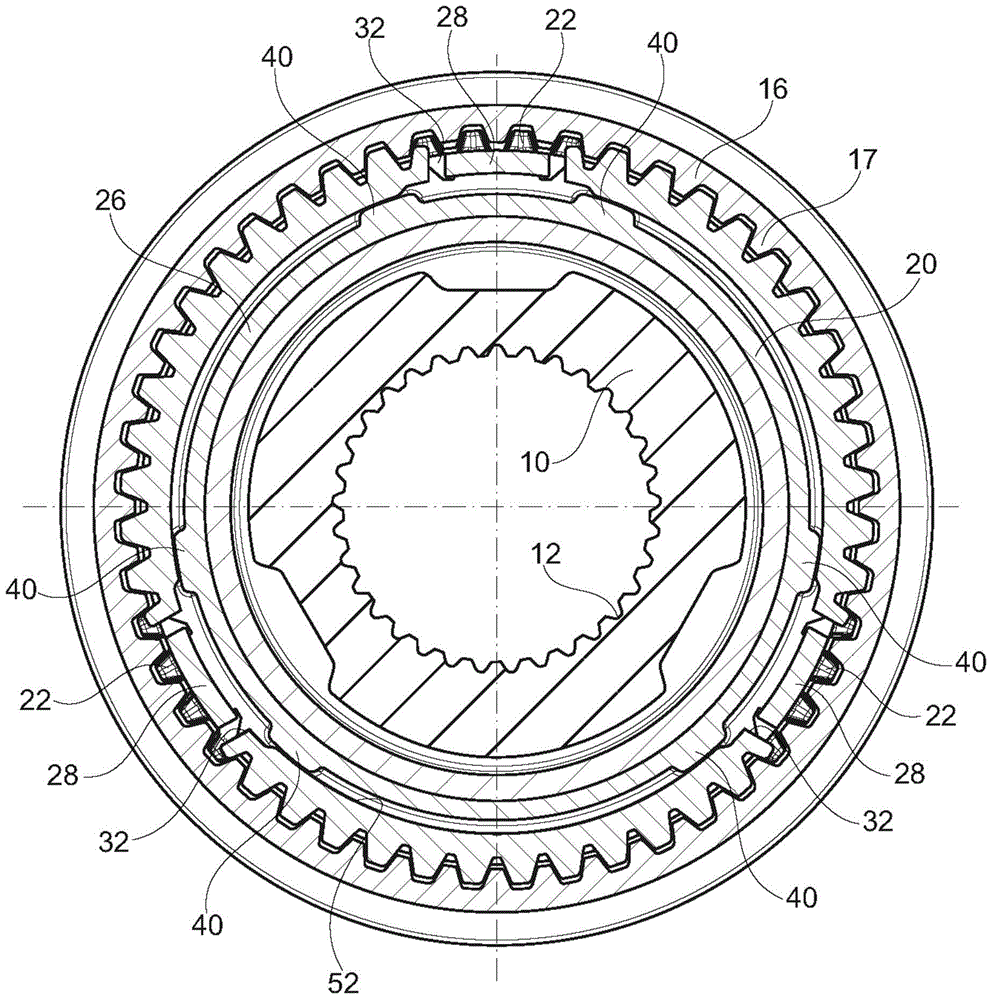

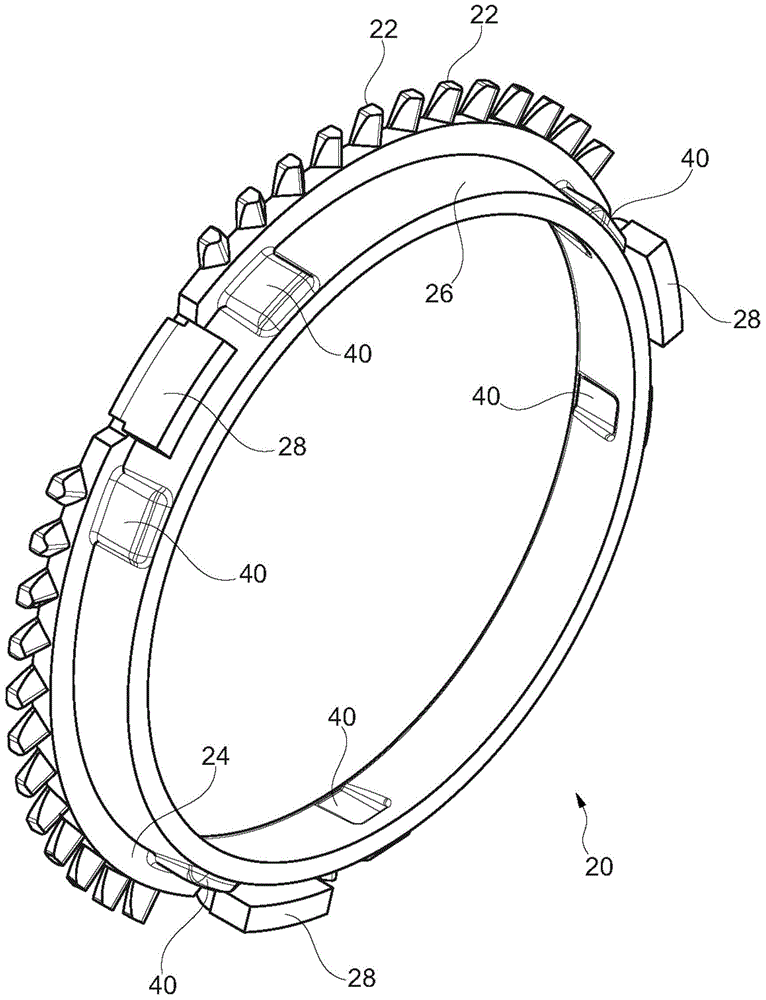

[0021] exist figure 1 A synchronization assembly 5 according to a first embodiment is shown in , which is used to connect the two drive gears 7 , 9 , shown schematically here, in a rotationally fixed manner to a drive shaft (not shown). Here, for the sake of simplicity, the transmission gears 7 , 9 are shown with the same diameter; in practice they have different diameters. It is of course also possible to assign only a single gear and thus a single transmission gear to the synchronization assembly.

[0022] The synchronizing unit 5 comprises a hub 10 (also referred to as synchronizing body), which is arranged on the drive shaft in a rotationally fixed manner by means of a hub toothing 12 . The drive shaft extends along a center axis M which is at the same time the center axis and the axis of rotation for the drive gears 7 , 9 and the synchronizing assembly 5 .

[0023] The drive gears 7 , 9 are arranged on the drive shaft as idler gears. When one of the gears is to be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com