Multi-path rotating joint

A rotary joint, multi-channel technology, applied in the direction of pipe components, etc., can solve the problems of low production efficiency, waste of material resources, easy wear of seals, etc., and achieve the effect of stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

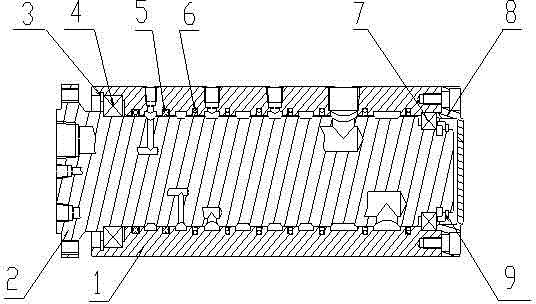

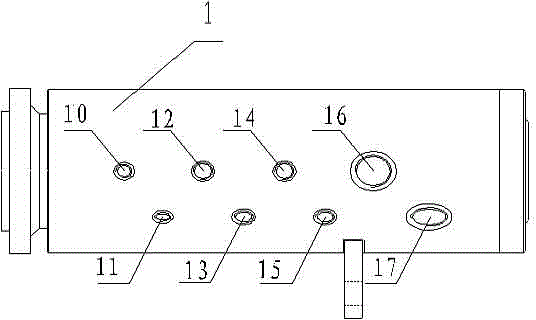

[0010] like figure 1 , figure 2 As shown, a multi-channel rotary joint includes a housing 1, an outer tube 2, a retaining ring 3 for holes, a first ball bearing 4, a seal 5, a first combination seal ring 6, a second ball bearing 7, and an end cover 8. The second combination retaining ring 9 is characterized in that: the two ends of the shell 1 and the outer tube 2 are supported by two ball bearings, the first ball bearing 4 and the second ball bearing 7, and the first ball bearing 4 and the second ball bearing Between the two ball bearings 7, there are seals 5 and a first combination seal ring 6 in sequence; two of the seals 5 are low-pressure seals, and seven first combination seal rings 6, the casing 1 and the outer The tube 2 is divided into 8 sealing areas. In the sealing area, the housing 1 and the outer tube 2 are respectively designed with a first passage 10, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com