Method for modeling light strips projected on cylinder surface based on sectional gray scale energy distribution

A cross-sectional grayscale energy, cylindrical surface technology, applied in the direction of measuring devices, optical devices, photogrammetry/video metrology, etc., can solve the problem of reducing model fitting accuracy, affecting the restoration of three-dimensional feature sizes, and inability to obtain accurate results, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

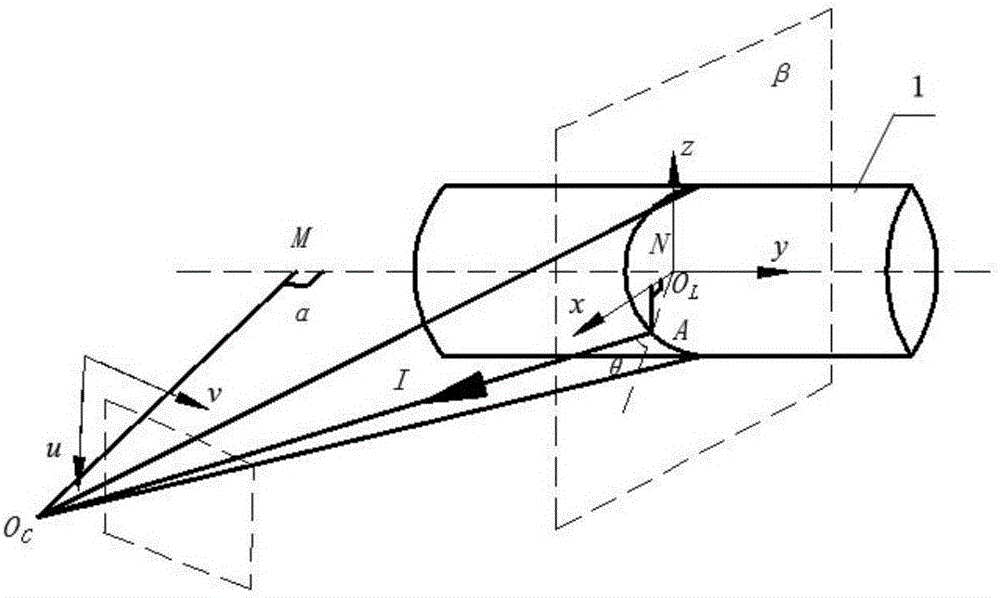

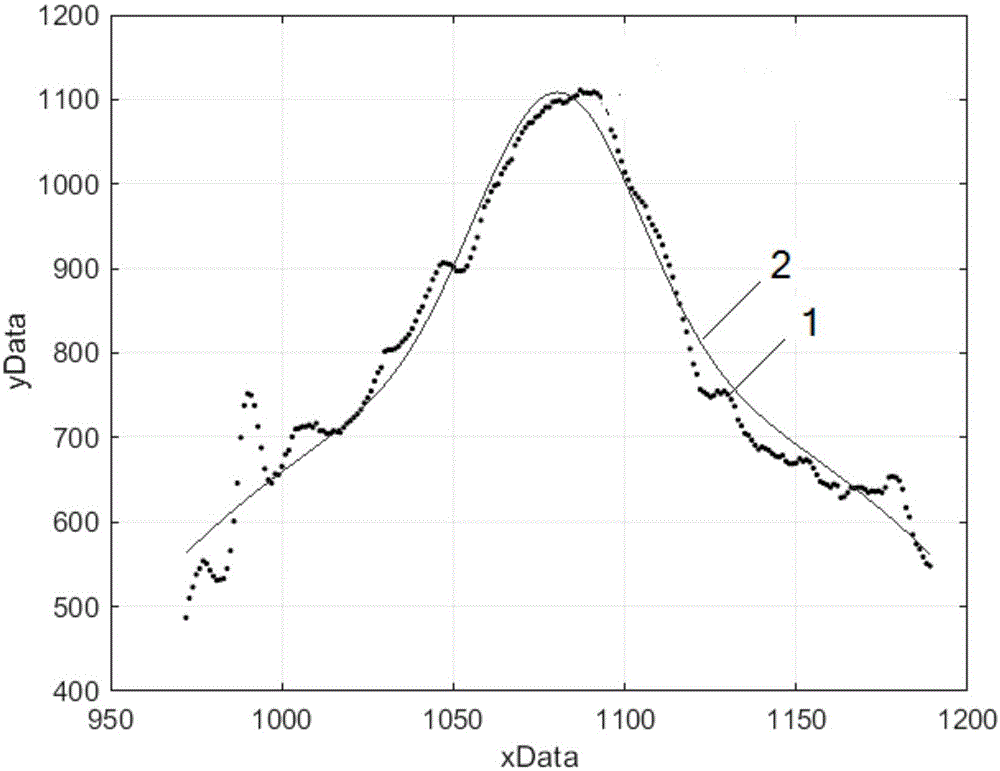

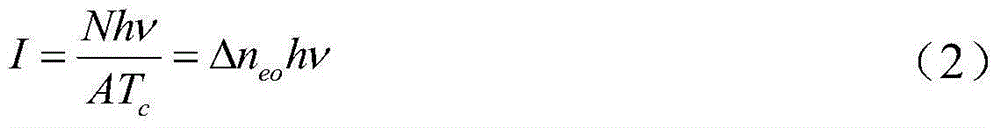

[0047] The specific implementation of the present invention will be further described in detail below regarding the technical solution for large field of view measurement of cylindrical workpieces and the light strip pictures taken by a single camera in the binocular stereo vision measurement system. Since the feature information is captured by the CCD camera after the laser light strip is reflected on the surface of the workpiece with a certain shape, the gray energy of the cross-section of the laser light strip captured by the CCD camera is accompanied by the information of the surface shape of the workpiece. Considering the actual spatial position and the workpiece Surface laser reflection characteristics, analyze the shape information of the workpiece attached to the laser light stripe gray energy on the image, and establish the gray energy distribution model of the light stripe section on the image.

[0048] The experimental shooting of the cylindrical workpiece to be meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com