Cam shaft phase sensor test method

A technology of phase sensor and testing method, which is applied in the direction of instruments, etc., can solve the problems of the influence of the detection accuracy of the axle phase sensor function, the high requirements of the operator, and the influence of the detection efficiency, so as to achieve high test efficiency, good test accuracy, and reduce detection cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

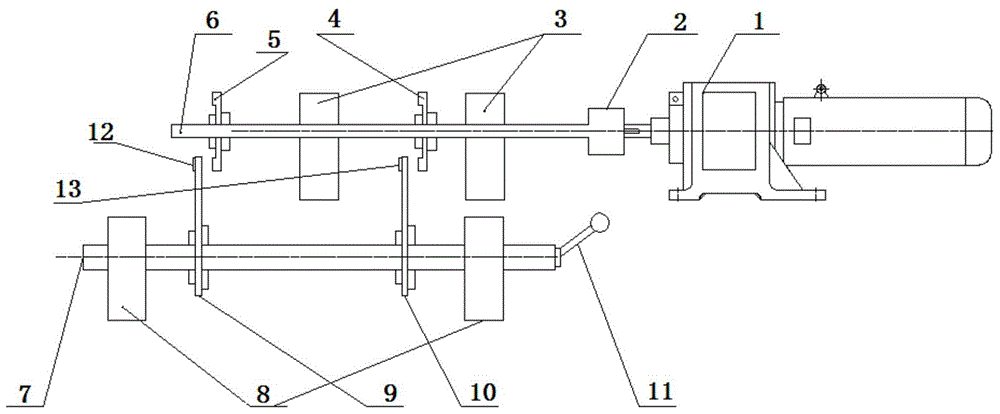

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0023] refer to figure 1 , the test method of camshaft phase sensor, specifically:

[0024] Install the first signal target wheel 5 and the second signal target wheel 4 with the same structure on the rotating shaft 6 connected with the motor 1;

[0025] Standard sample fixed cantilever 9 and test sample fixed cantilever 10 are installed on the fixed shaft 7, the sensor standard part 12 of testing first signal target wheel 5 rotation phase is installed on the standard sample fixed cantilever 9, and the test sample is fixed on the cantilever 10 A sensor test piece 13 for testing the rotational phase of the second signal target wheel 4 is installed;

[0026] The distance between the sensor standard part 12 and the first signal target wheel 5 is equal to the distance between the standard samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com