Plate leveling method for plate jointing operation in shipbuilding plane section assembly line

A plane segmentation and assembly line technology, which is applied to ship parts, ship construction, ships, etc., can solve the problems of long time-consuming and low efficiency of jigsaw work, so as to improve work efficiency, improve jigsaw work efficiency, fast, effective and accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

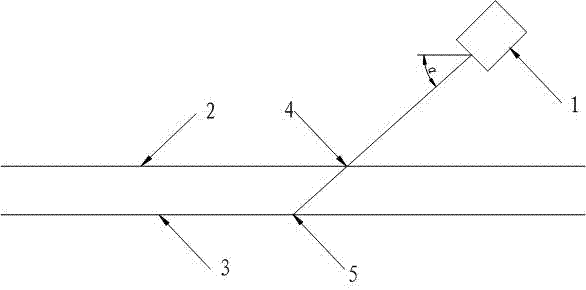

[0017] refer to figure 1 As shown, the schematic diagram of the one-line laser panel operation shows that in the process of the panel operation, the one-line laser 1 is used to emit laser lines at an angle of 45 degrees from the horizontal direction to different boards. Simultaneous projection of surfaces (such as figure 1 The angle α mentioned in is 45 degrees), the intersection point of the laser line reaching the board surface is different, there are different intersection points 4 and 5, indicating that there is a high board surface 2 and a low board surface 3, the operator intuitively judges according to the intersection point information, and then Quickly and effectively adjust the board surface to achieve the same height.

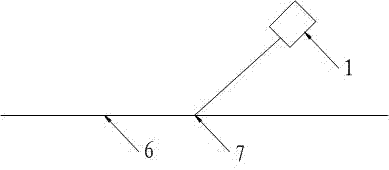

[0018] Such as figure 2 As shown, when the intersection point 7 where the laser line reaches the plate surface 6 is the same, it indicates that the heights of different plate surfaces are the same.

[0019] Of course, the angle at which the line ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com