Fixed-point collection device for rubidium filled in rubidium bulbs

A collection device and rubidium amount technology, applied in the aerospace field, can solve the problems of difficult control of rubidium bubble quality, large deviation of rubidium amount, waste of raw materials, etc., and achieve the effects of saving precious raw materials, easy control of contact force, and convenient accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

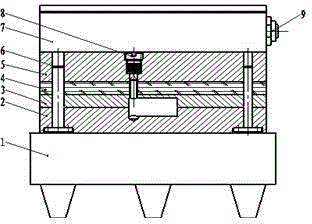

[0022] Such as figure 1 As shown, the rubidium bubble is filled with a fixed-point collection device for rubidium, which includes a heating device 1 and a metal cavity placed on the heating device 1, a refrigerant circulation box 7 and a cooling body 5.

[0023] The metal mold cavity is composed of a lower cavity 2 and an upper cavity 3 with built-in rubidium bubbles connected together. The bottom of the lower cavity 2 is connected to the heating device 1; the top of the upper cavity 3 is provided with a heat insulation layer 4. A cooling body 5 is provided on the heat insulation layer 4; a cooling body core assembly 8 is provided on the upper part of the cooling body 5, and the cooling body core assembly 8 is connected with the refrigerant circulation box 7; the cooling body core assembly 8 passes through the heat insulation layer 4 is in contact with the rubidium bubble; the two ends of the bottom of the lower cavity 2 are respectively provided with a guide column 6 which pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com