Fault injection device

A fault injection and fault technology, applied in the direction of electrical testing/monitoring, etc., can solve problems such as false reporting of the electronic control module under test, troublesome definition and editing of fault signals, failure to guarantee the pulse cycle of square wave signals or the integrity of analog signals, etc. To achieve the effect of synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Introduced below are some of the various embodiments of the invention, intended to provide a basic understanding of the invention. It is not intended to identify key or critical elements of the invention or to delineate the scope of protection.

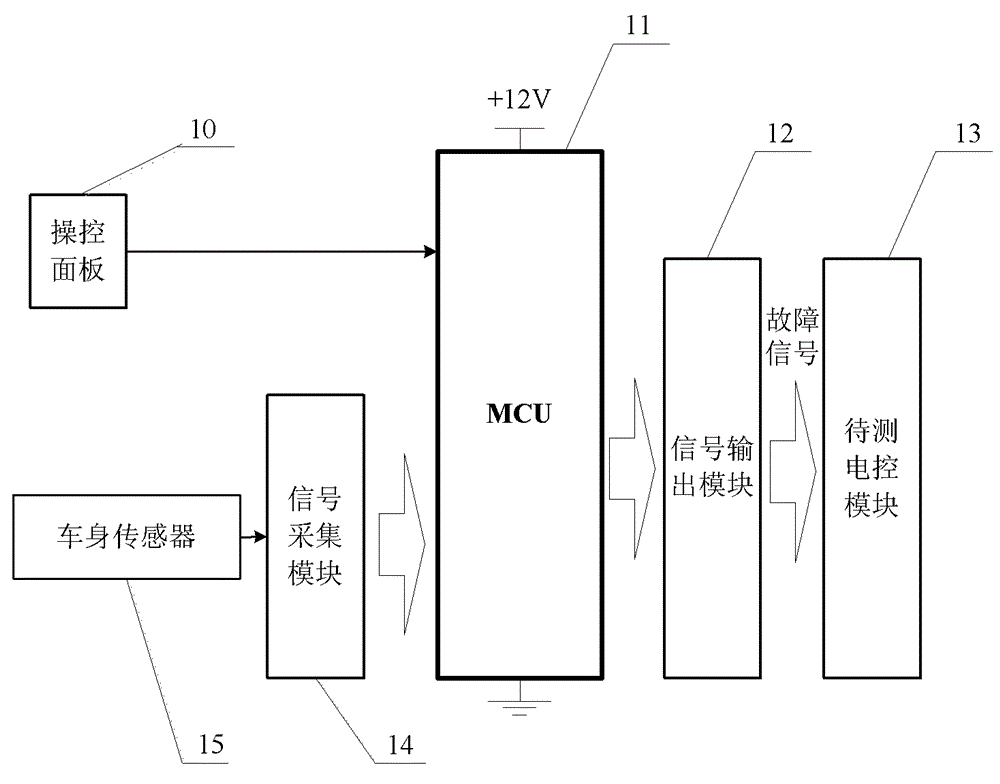

[0053] figure 1 is a structural block diagram of the fault injection device of the present invention. Refer below figure 1 The fault injection device of the present invention will be described.

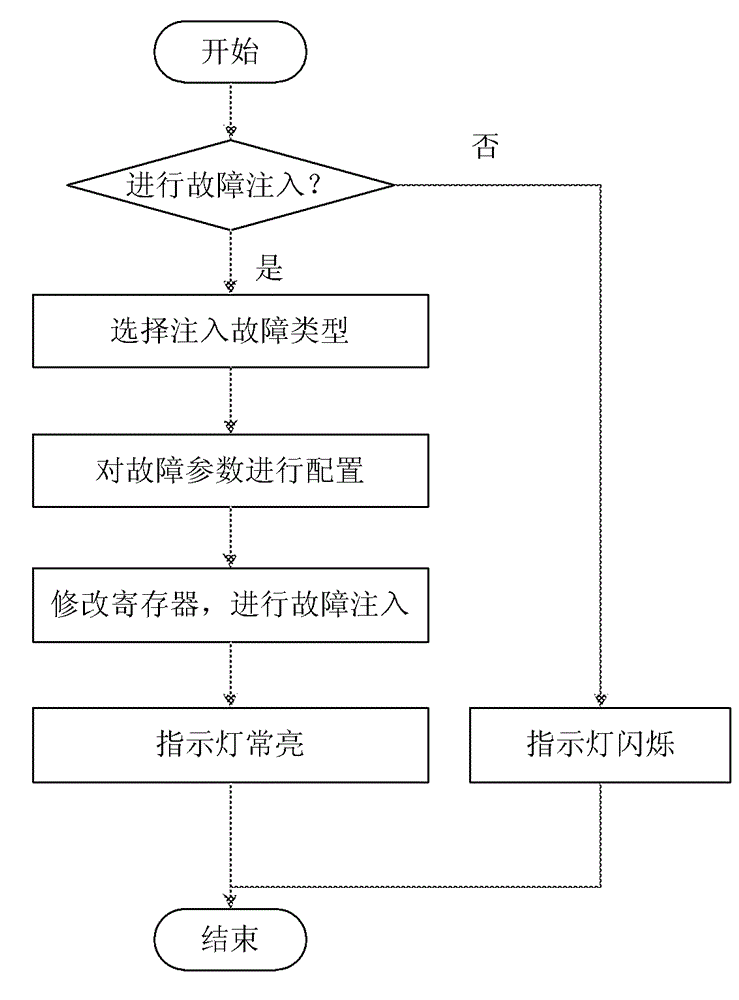

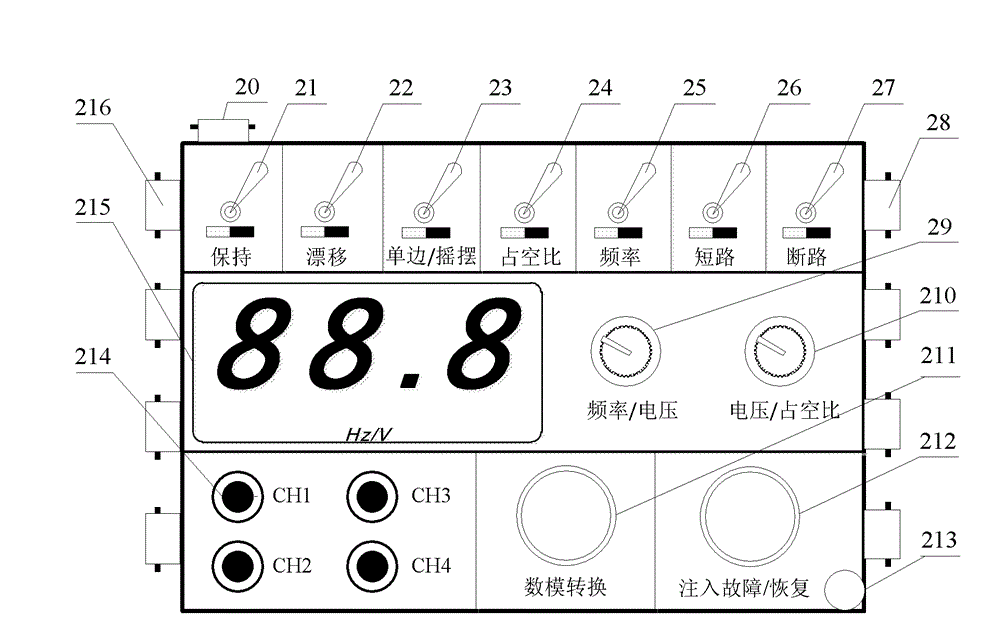

[0054] Such as figure 1 As shown, the fault injection device of the present invention has: an operation panel 10, which is used to set the type of fault signal that needs to be injected; The structural part of the fault injection device, but refers to the signal of the sensor on the vehicle body) to filter and shape the original signal to input the following MCU; MCU (microprocessor) 11, in the case of fault injection mode, according to the slave operation The type of the fault signal that needs to be injected is received by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com