Plug-socket in gap-free fit

A plug, socket and plug technology, applied in the direction of contact parts, etc., can solve the problems of power consumption, reduce the service life of electrical appliances, hidden dangers of electrical appliances, etc., and achieve the effect of simple design structure, prolonging service life, and convenient and quick manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

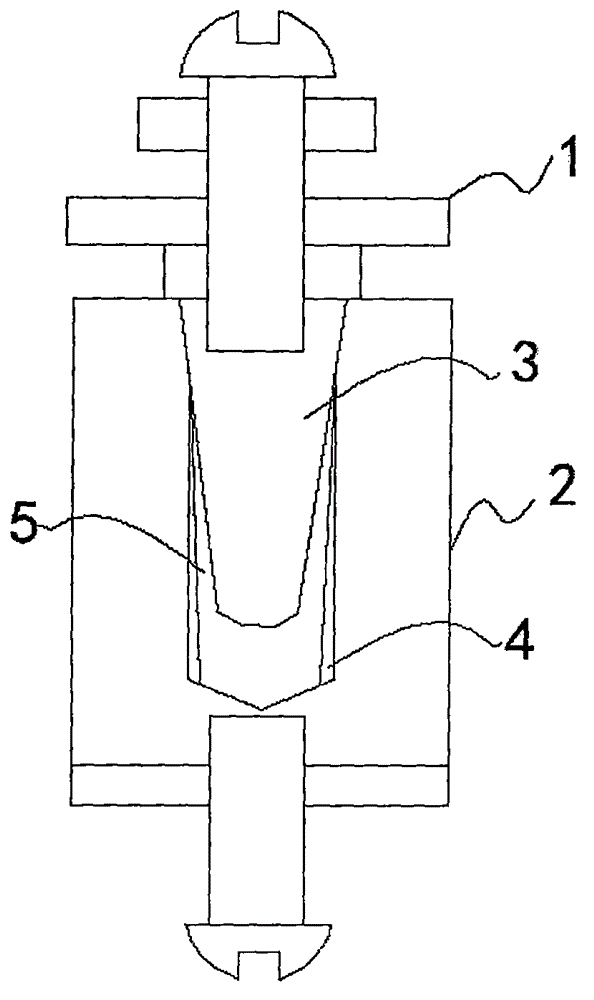

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A plug and socket with no clearance fit, including a plug 1 and a socket 2, the plug mainly includes a plug body and a plug electrode 3 fixed on the plug body, and the socket includes a box-shaped socket body and a jack on it. The contact piece 4 of the plug electrode is arranged in the jack of the socket; the plug electrode 3 is set as a conical convex body, and the contact piece 4 is set as a conical concave body matched with the conical convex body of the plug electrode, and the conical convex body and the conical convex body The cone angle 5 of the concave body is 0.2 to 15 degrees.

[0014] The conical convex body and the conical concave body of the present invention are made of copper or aluminum. The number of the conical convex body and the conical concave body is more than one. There are three conical convex bodies and conical concave bodies arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com