Stripping device of cable insulation shielding layer

A cable insulation and shielding layer technology, which is applied in the field of cable insulation and shielding layer stripping devices, can solve the problems of inconvenient tool replacement and height adjustment, low cutting precision of insulation layer, and reduced cable insulation, so as to improve cutting accuracy and facilitate The effect of high tool height and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

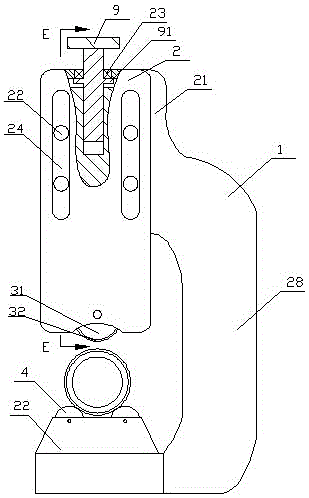

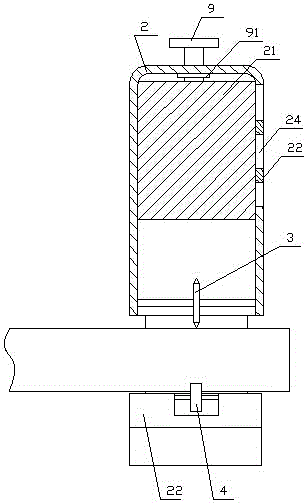

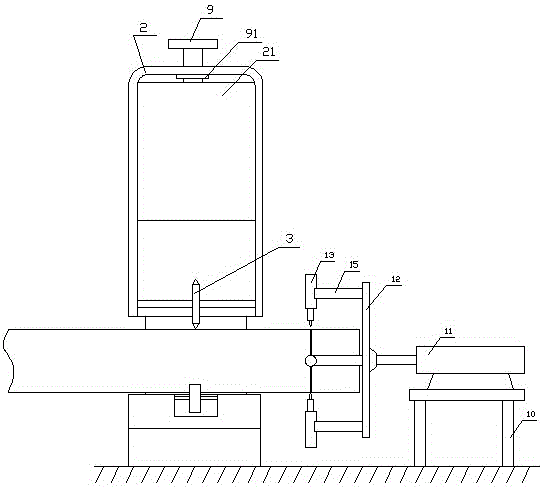

[0023] Refer to attached figure 1 , The cable insulation and shielding stripping device of the present invention includes a bracket 1, the upper part of the bracket 1 is slidably connected with a height-adjustable knife rest 2, the upper part of the bracket 1 is provided with a slider 21, and the knife rest 2 is slidably connected to the slider 21 . In this embodiment, the tool rest 2 is a U-shaped connecting plate, and the U-shaped connecting plate includes a top plate and two side plates that are affixed to the two ends of the top plate and extend downward. Adjusting screws 9 are installed between the top plate and the slider 21, and the slider 21 is provided with a screw hole with an upward opening, and the adjusting screw 9 passes through the top plate and is screwed in the above screw hole. The adjusting screw 9 is provided with a ring platform 91, and the ring platform 91 contacts with the lower surface of the top plate. Bearing 23 is installed between, and adjusting sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com