Torsional vibration damping transmission element

A technology of transmission components and transmission components, applied in the direction of rotation vibration suppression, spring/shock absorber, components with teeth, etc., can solve problems such as large preload torque, complex cost, large friction loss and meshing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

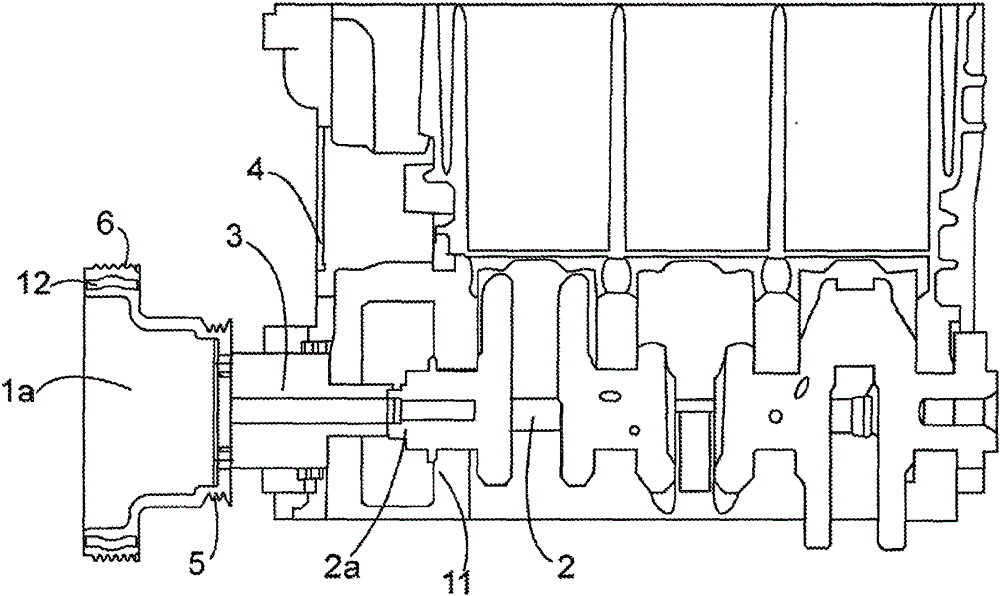

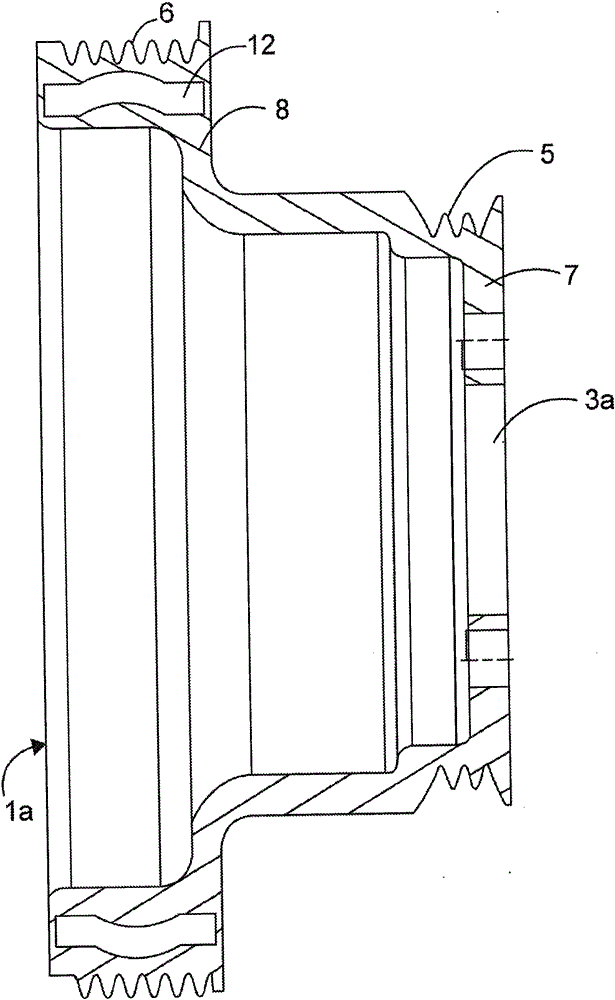

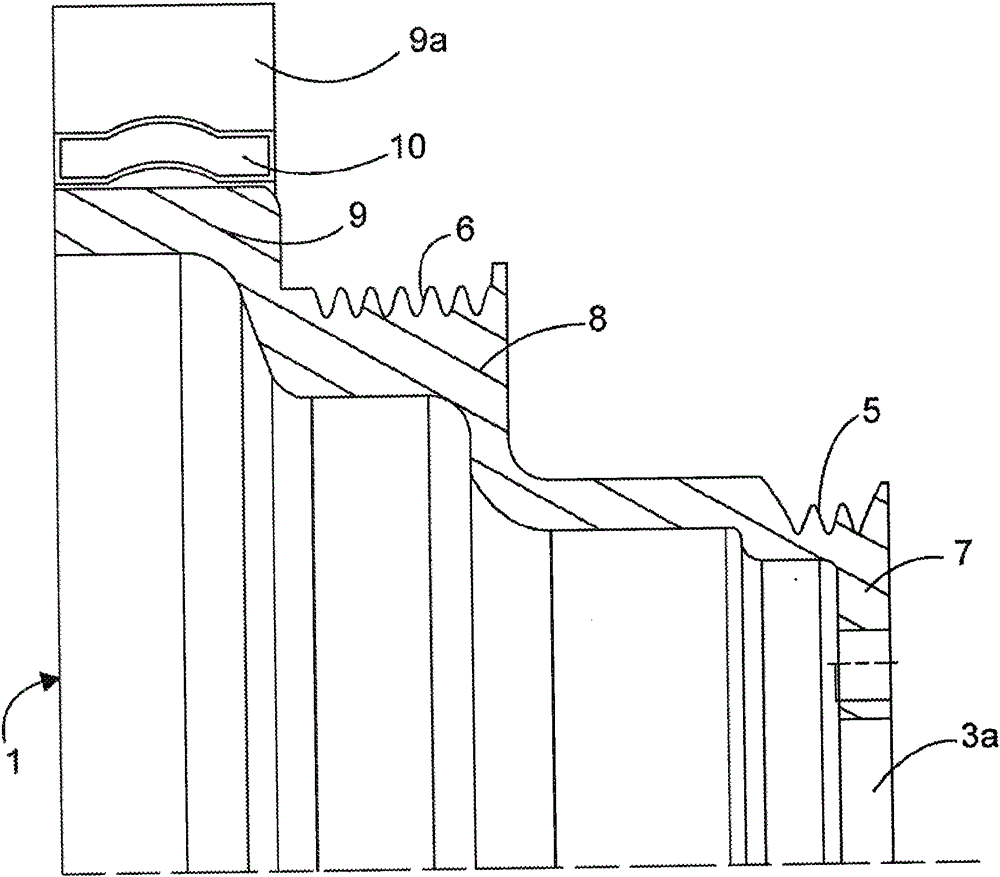

[0029] In the following, the transmission element is considered as a pulley connected to one end of the crankshaft, which represents the drive shaft. This is not restrictive, the transmission element may be any other element interposed between the driving shaft and the driven shaft.

[0030] as from figure 1 As can be seen in , the pulley 1 a is coupled to the end 2 a of the crankshaft 2 , opposite the hub 3 which passes through the opening in the housing surface 4 . The end of the hub 3 of the pulley 1a is inserted into the interior of the corresponding end 2a of the crankshaft 2 to be integrated with said end 2a by any method such as tightening screws and threads, forging, riveting or the like.

[0031] At the end 2a oriented towards the pulley 1a, the crankshaft 2 can be held by the last crankshaft bearing 11 of a set of crankshaft bearings inside the housing, the last crankshaft bearing 11 being the closest of the set of crankshaft bearings to the end 2a one. The last c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap