Electric heating wok with automatic vegetable cutting device

A vegetable cutting device and electric heating technology, applied in metal processing, inserts, cooking utensils and other directions, can solve the problems of occupying a large space, inconvenient to use, inconvenient to save and manage, etc., to achieve easy management, improve work efficiency, Structured novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

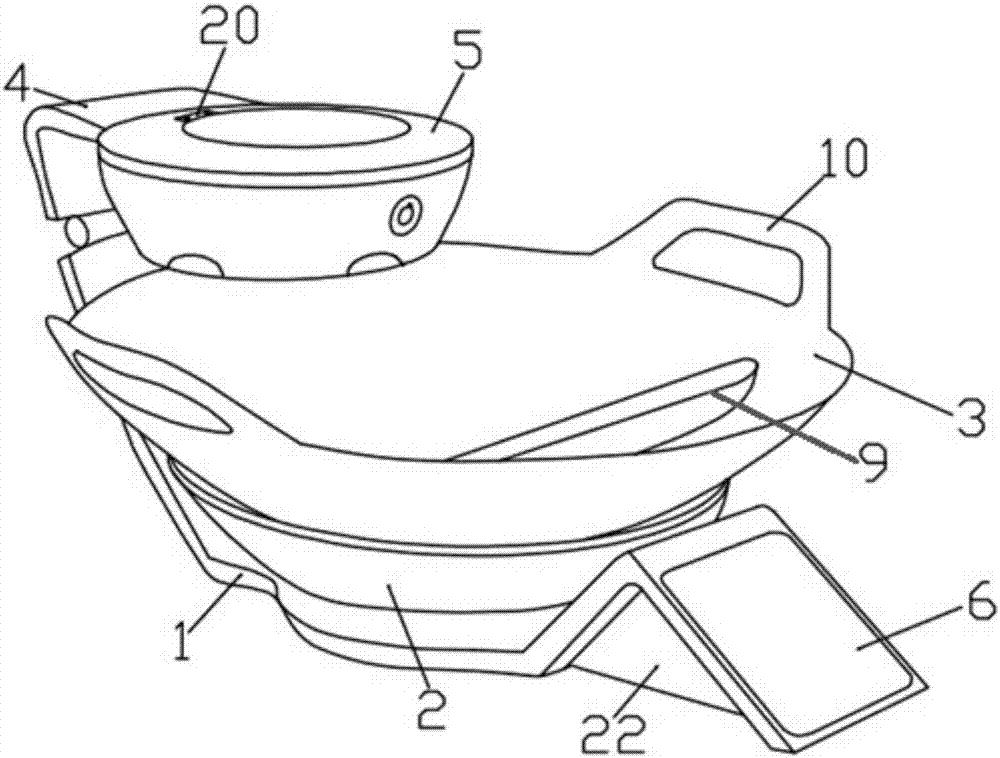

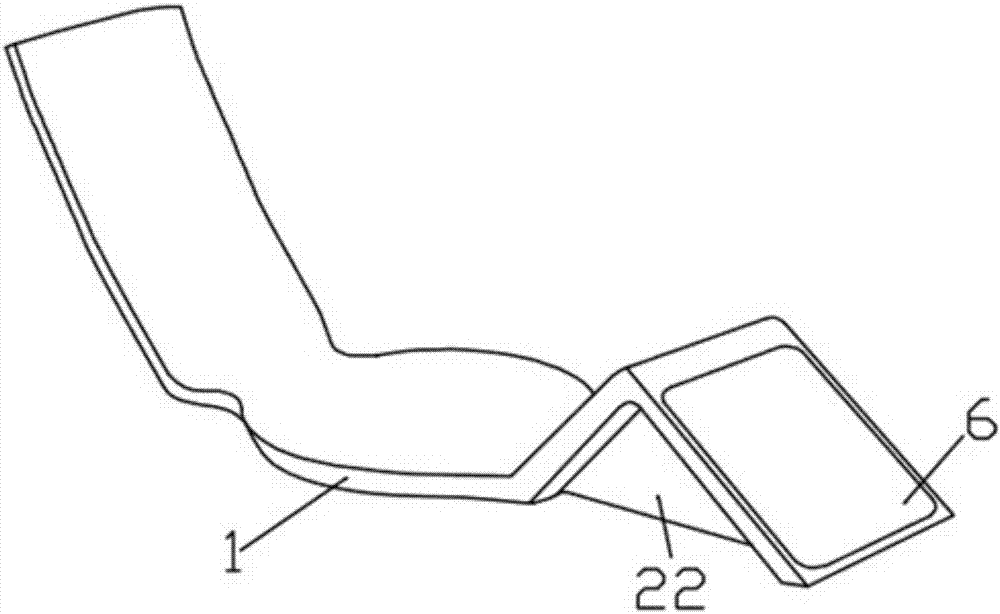

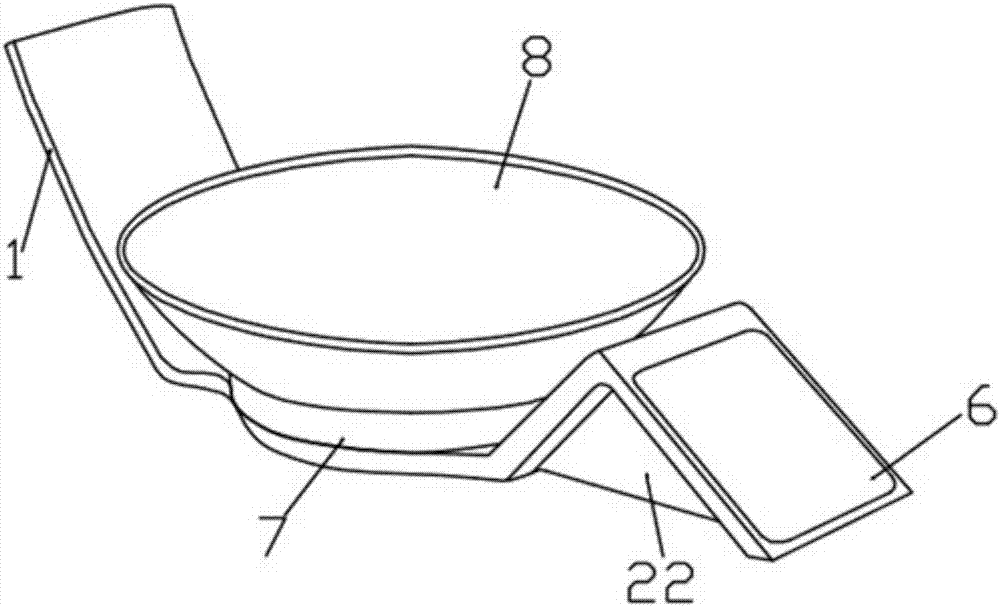

[0027] Example: such as Figure 1-Figure 6 As shown, an electric heating frying pan with an automatic vegetable cutting device includes a base 1, a heating furnace 2, a pot body 3, an installation part 4 and a vegetable cutting machine 5. The middle part of the base 1 is disc-shaped, and the base 1 One end is in the shape of an "L", the other end is arc-shaped and extends upwards. A panel 6 for controlling the heating furnace 2 is installed on one end of the base 1; Plate 7, the upper part of the heating furnace 2 is a furnace body 8 for generating magnetic field-induced eddy currents, a circuit board is installed inside the furnace body 8, a coil is provided on the circuit board, and the panel 6 is connected with the circuit board by a wire; the pot body 3 Placed above the furnace body 8, a partition 9 is provided inside the pot body 3, and the partition plate 9 divides the pot body 3 into two grids, and pot ears 10 are provided on both sides of the pot body 3; the vegetable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com