Ultrasonic and microwave combined reaction system that can improve opening and closing stability

A combined reaction and ultrasonic technology, applied in the field of ultrasonic and microwave combined reaction systems, can solve the problems of loose connection, ultrasonic and microwave overflow, deviation, etc., and achieve the effect of improving opening and closing stability and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

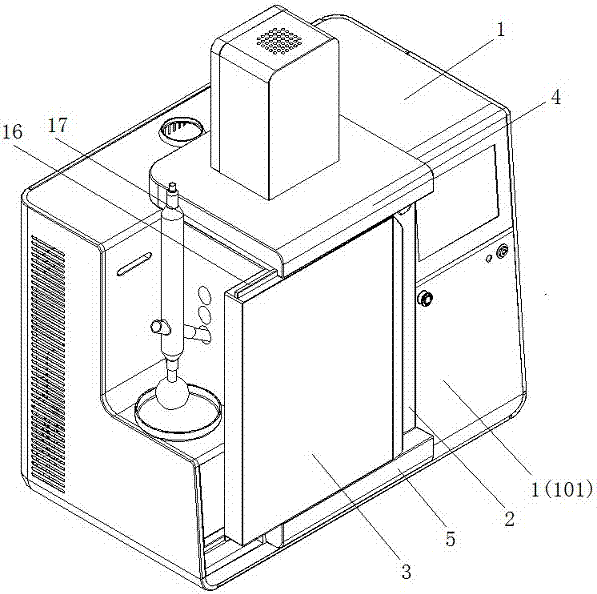

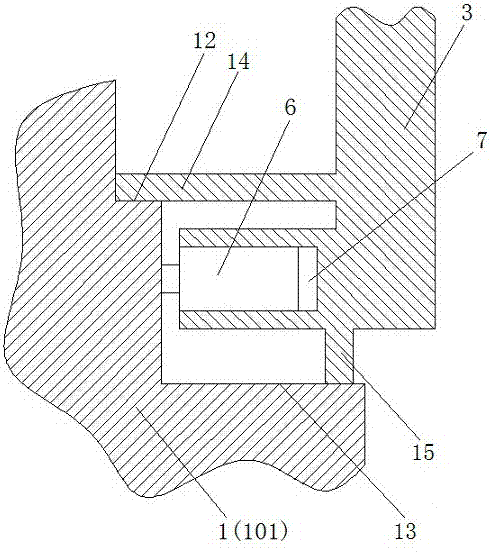

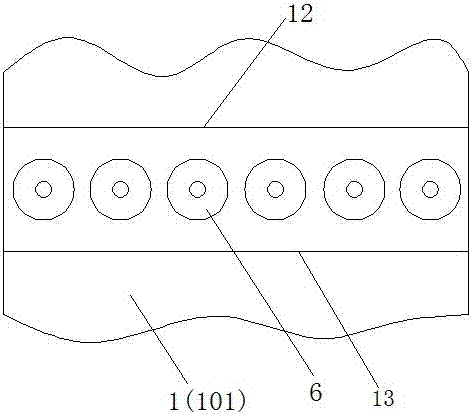

[0020] Such as figure 1 , figure 2 and image 3 An ultrasonic and microwave combined reaction system that can improve the opening and closing stability is shown, which includes a reaction chamber 1, an ultrasonic reaction device and a microwave reaction device are arranged inside the reaction chamber 1, and a side end surface of the reaction chamber 1 is provided with The port 2 is placed, and the corresponding position of the port 2 is provided with a sliding door 3; in the reaction chamber 1, the side end face where the port 2 is placed is the end face 101, and the upper and lower sides of the end face 101 are placed The upper guide rail 4 and the lower guide rail 5 extending horizontally are arranged respectively, and the sliding door 3 extends between the upper guide rail 4 and the lower guide rail 5; a plurality of support rollers are arranged on the placement end surface 101 6. The axis of each support roller 6 is perpendicular to the placement end surface 101, and it...

Embodiment 2

[0028] As an improvement of the present invention, at least one supporting end surface extending in the horizontal direction is provided in the placement end surface 101, and an auxiliary support plate is provided in the opposite end surface of the sliding door 3 and the placement end surface 101, It extends above the support end face. With the above-mentioned design, it can improve the stability of the sliding door during the moving process through the mutual support between the supporting end surface and the auxiliary supporting plate, and can further share the pressure on the supporting rollers.

[0029] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0031] As an improvement of the present invention, a first support end surface 12 and a second support end surface 13 extending in the horizontal direction are arranged on the placement end surface 101, wherein the first support end surface 12 is located above the second support end surface 13 , a plurality of support rollers 6 are arranged between the first support end surface 12 and the second support end surface 13; in the sliding door, the upper end surface and the lower end surface of the support track 7 are respectively in contact with the upper end surface and the lower end surface of the support roller A first auxiliary support plate 14 extending horizontally to the first support end surface 12 is provided on the opposite end surface of the sliding door and the placement end surface, and a first auxiliary support plate 14 extending vertically to the second support end surface 13 is provided. The second auxiliary support plate 15 on. With the above-mentioned design, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com