Bulk material rocking type sieving machine with sieving body additionally provided with anti-blockage comb

A technology for bulk materials and sieves, applied in solid separation, sieves, grills, etc., can solve problems such as unseen technical solutions, pauses, and coal sieving machines cannot operate normally, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

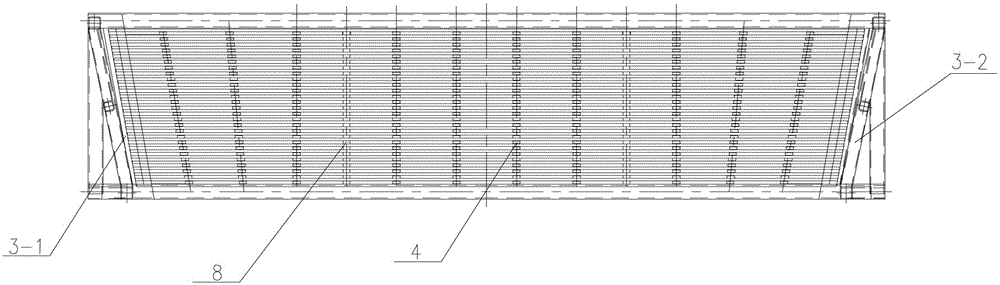

[0022] refer to figure 1 , the screening machine of the present invention includes a complete machine frame 1, a hopper 2 for introducing incoming materials into the screen body, a plane screen body 3 installed obliquely relative to the ground, and a reciprocating swing driving device 5 for the screen body composed of a motor, a reduction mechanism, and a transmission component. .

[0023] see picture figure 1 , figure 2 , image 3 , the sieve body 3 is made up of a sieve frame 3-2 and a sheet-shaped sieve bar 3-1 connected to the sieve frame to form a screen. In this embodiment, the sieve bars are arranged perpendicular to the material flow direction (that is, the length direction is horizontal).

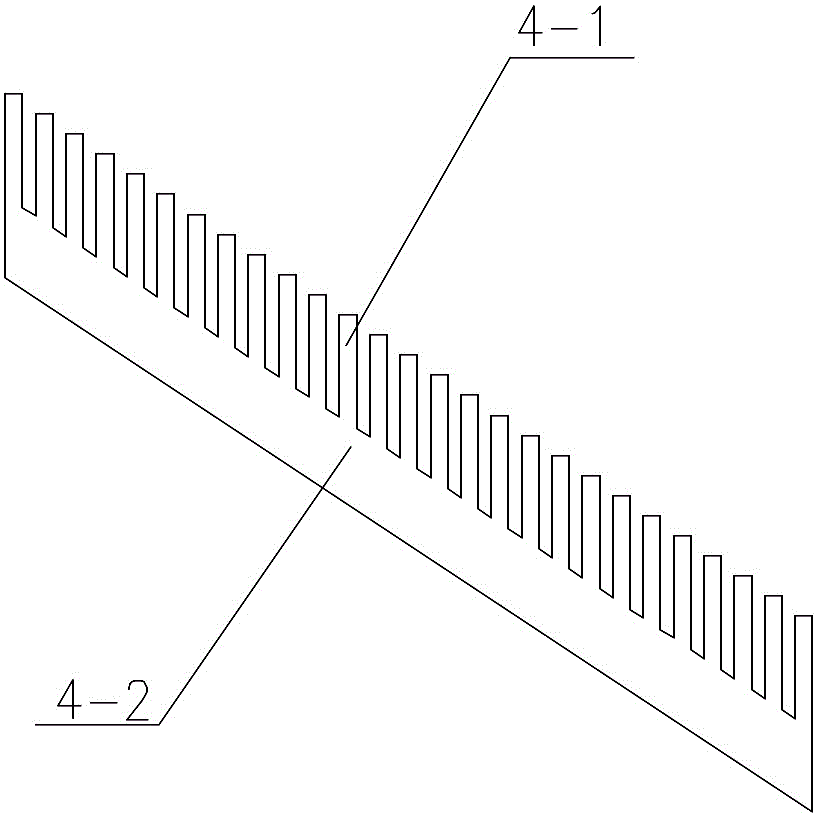

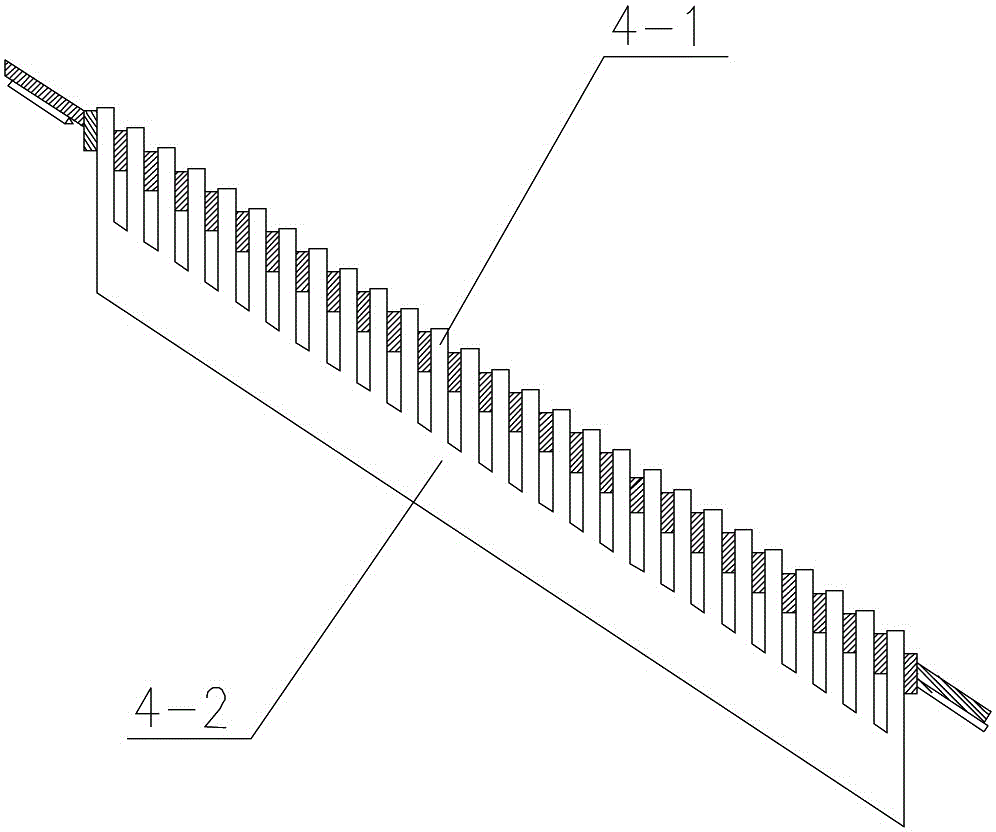

[0024] refer to figure 1 , Figure 4 , Figure 5 , the anti-blocking comb 4 located under the sieve body is composed of comb teeth 4-1 and a tooth seat (comb back) 4-2 that fixes multiple comb teeth in a row. The two side surfaces of the two sides form an inclined plane to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap