A method to reduce blast furnace slag ratio

A blast furnace slag and blast furnace slag technology are applied in the field of reducing blast furnace slag ratio, and can solve the problems of affecting blast furnace smelting efficiency, increasing furnace resistance, increasing slag ratio, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The composition of raw materials and fuels for blast furnace ironmaking in a steel plant is shown in Table 2. Blast furnace smelting conditions: coke ratio is 400kg / t 铁 , Coal ratio is 150kg / t 铁 The charge structure of the blast furnace is that the amount of iron brought in by the mixed iron ore powder used for sintering accounted for 80%, the amount of iron brought in by pellets accounted for 15%, and the iron ore brought in by natural lump ore accounted for 5%.

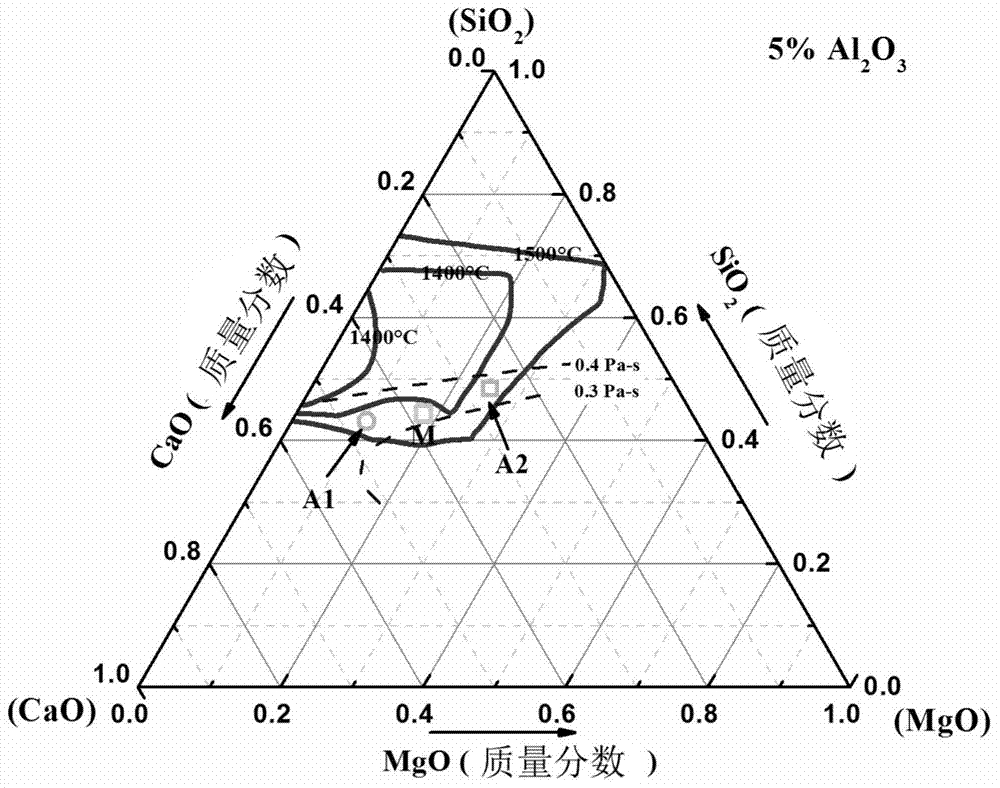

[0029] The components of the blast furnace slag are CaO=39.57%, SiO 2 =33.25%, Al 2 o 3 =15.88% and MgO=11.30%, the slag ratio is 305.6kg / t 铁 . Using the method of the present invention, without changing the above smelting conditions, the components of the blast furnace slag are adjusted to CaO=22.89%, SiO 2 =37.54%, Al 2 o 3 = 17.94% and MgO = 21.63%. The melting point and viscosity of the slag before and after the adjustment are equal, and the slag ratio is reduced to 270.6kg / t after the adjustment...

Embodiment 2

[0033] The composition of raw materials and fuels for blast furnace ironmaking in a steel plant is shown in Table 2. Blast furnace smelting conditions: coke ratio is 400kg / t 铁 , Coal ratio is 150kg / t 铁 The charge structure of the blast furnace is that the amount of iron brought in by the mixed iron ore powder used for sintering accounted for 100%, the amount of iron brought in by pellets accounted for 0%, and the iron ore brought in by natural lump ore accounted for 0%.

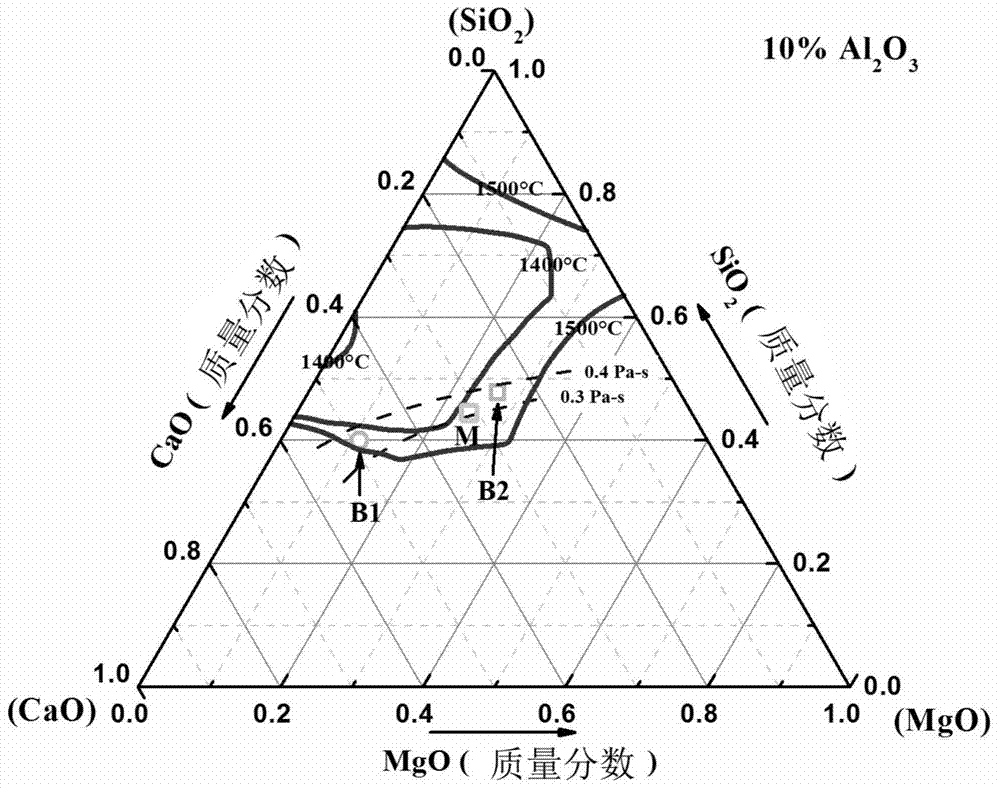

[0034] The components of the blast furnace slag are CaO=39.45%, SiO 2 =33.15%, Al 2 o 3 =15.73% and MgO=11.67%, the slag ratio is 328.0kg / t 铁 . By adopting the method of the present invention, without changing the above smelting conditions, the composition of the slag is adjusted to CaO=23.24%, SiO 2 =37.49%, Al 2 o 3 = 17.79% and MgO = 21.48%. The melting point and viscosity of slag before and after adjustment are equal, and the slag ratio after adjustment is reduced to 290.0kg / t 铁 , a decrease of ...

Embodiment 3

[0036] The composition of raw materials and fuels for blast furnace ironmaking in a steel plant is shown in Table 2. Blast furnace smelting conditions: coke ratio is 400kg / t 铁 , Coal ratio is 150kg / t 铁 The charge structure of the blast furnace is that the amount of iron brought in by the mixed iron ore powder used for sintering accounted for 90%, the amount of iron brought in by pellets accounted for 10%, and the iron ore brought in by natural lump ore accounted for 0%.

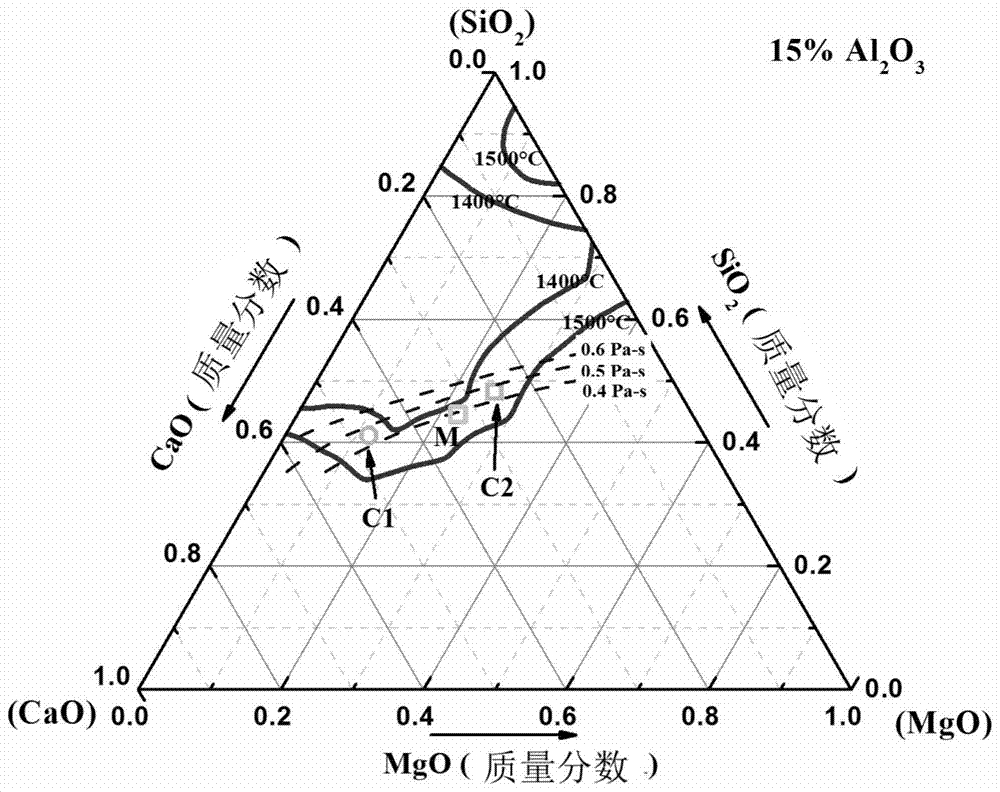

[0037] The original blast furnace slag components of the blast furnace are CaO=39.60%, SiO 2 =33.25%, Al 2 o 3 =15.71% and MgO=11.44%, the slag ratio is 315.6kg / t 铁 . Using the method provided by the present invention, without changing the above smelting conditions, the composition of blast furnace slag is adjusted to CaO=22.89%, SiO 2 =37.52%, Al 2 o 3 = 17.74% and MgO = 21.85%. The melting point and viscosity of slag before and after adjustment are equal, and the slag ratio after adjustment is redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com