Drainable drill sleeve

A drill sleeve and sleeve technology, which is applied in the direction of drill bits, drilling tools, drilling equipment, etc., can solve the problems of affecting mining speed, mining efficiency is not effective, and the set function is single, so as to achieve the effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

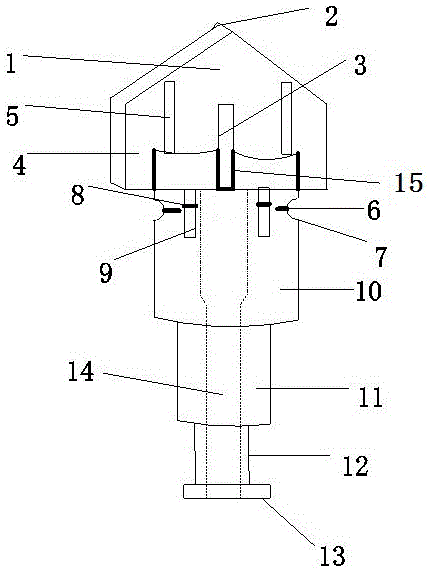

[0019] In view of the above problems, the purpose of the present invention is to provide a drainable drill sleeve, which is provided with a limit hole and a hollow drainage tube on the drill sleeve, which enhances the fixation of the drill bit connection, saves the external drainage tube, and is equipped with a set The drill bit of the drainage groove is improved, which improves the overall work efficiency.

[0020] In order to achieve the above object, the present invention adopts the following technical solutions

[0021] Drainable drill bit sleeve, which includes drill bit 1, cutting edge 2, clamping shaft 3, rotating shaft 4, diversion groove 5, first limiting hole 6, limiting groove 7, second limiting hole 8, fixed A shaft 9, a primary sleeve 10, a secondary sleeve 11, a tertiary sleeve 12, a sleeve cap 13, a through hole 14, and a slot 15.

[0022] The drill bit 1 includes a cutting edge 2, a clamping shaft 3, a rotating shaft 4, and a fixed shaft 9. The cutting edge 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap