Burner head structure for a gas grill

A technology for barbecue stoves and gas stoves, which is applied in the directions of burners, combustion methods, combustion types, etc., can solve the problems of burning ingredients, stove head pollution, and heavy weight, and achieve the effect of strengthening structural strength and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

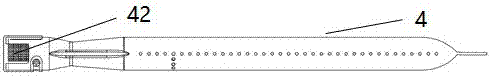

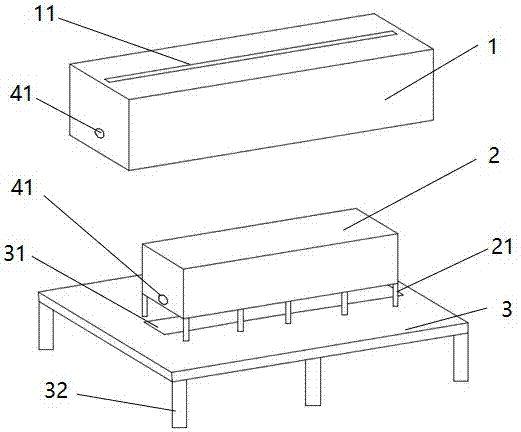

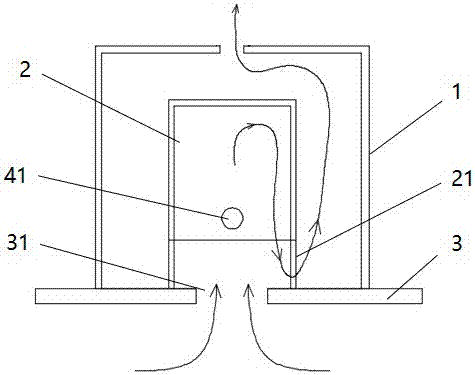

[0022] Embodiment 1: A burner structure for a gas grill, comprising a heat-gathering outer cover 1, an inner heat-preservation cover 2, a mounting plate 3, and a gas burner 4; the heat-retaining inner cover 2 has several pillars 21; the mounting plate 3 has a vent 31 in the middle; the heat preservation inner cover 2 is set on the vent 31 of the mounting plate 3; the heat collecting outer cover 1 has a heating port 11 on the top; the heat collecting outer cover 1 is set in the heat preservation The outside of the cover 2; the heat-gathering outer cover 1 and the heat-preservation inner cover 2 are provided with a gas burner installation hole 41;

Embodiment 2

[0023] Embodiment 2: A burner structure for a gas grill, including a heat-gathering outer cover 1, a heat-insulating inner cover 2, a mounting plate 3, and a gas burner 4; the heat-retaining inner cover 2 has several pillars 21; the mounting plate 3 has a vent 31 in the middle; the heat preservation inner cover 2 is set on the vent 31 of the mounting plate 3; the heat collecting outer cover 1 has a heating port 11 on the top; the heat collecting outer cover 1 is set in the heat preservation The outside of the cover 2; the heat gathering outer cover 1 and the heat preservation inner cover 2 are provided with a gas burner installation hole 41; the gas burner 4 passes through the gas burner installation hole 41 and is arranged inside the heat preservation inner cover 2, The heat-gathering outer cover 1 , the thermal insulation inner cover 2 and the mounting plate 3 are all high-temperature-resistant ceramic materials.

Embodiment 3

[0024] Embodiment 3: A burner structure for a gas grill, comprising a heat-gathering outer cover 1, a heat-preservation inner cover 2, a mounting plate 3, and a gas burner 4; the heat-retaining inner cover 2 has several pillars 21; the mounting plate 3 has a vent 31 in the middle; the heat preservation inner cover 2 is set on the vent 31 of the mounting plate 3; the heat collecting outer cover 1 has a heating port 11 on the top; the heat collecting outer cover 1 is set in the heat preservation The outside of the cover 2; the heat gathering outer cover 1 and the heat preservation inner cover 2 are provided with a gas burner installation hole 41; the gas burner 4 passes through the gas burner installation hole 41 and is arranged inside the heat preservation inner cover 2, The lower surface of the mounting board 3 has a plurality of supporting feet 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com