A method and equipment for automatic speed regulation control method and equipment of shredding machine based on material bulk density accumulation algorithm

A technology of shredder and bulk density, applied in the field of tobacco production, can solve the problems of lack of bulk density of tobacco materials, and achieve the effects of broad application prospects, improved product quality, and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

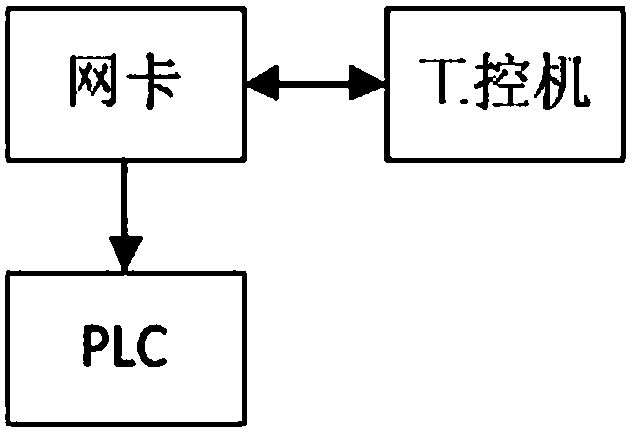

Image

Examples

Embodiment Construction

[0028] Embodiment Using the automatic speed regulation control method of the shredding machine based on the accumulation algorithm of material bulk density of the present invention, in May 2015, the shredding process of Baisha fine second-generation tobacco leaves was carried out automatic speed regulation control on the YS213A type shredding machine. The steps are as follows:

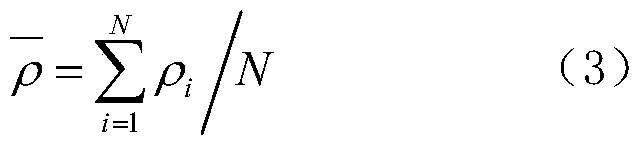

[0029] (a) Calculate the initial material bulk density ρ of tobacco leaves 0

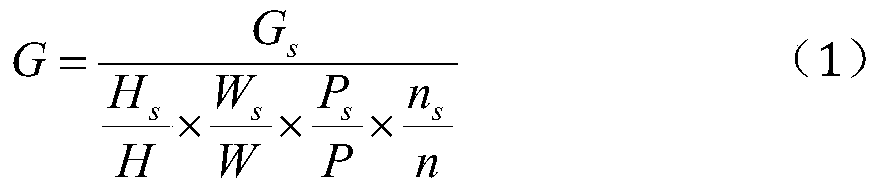

[0030] (a-1) Put Baisha fine second-generation tobacco leaves into the shredding machine, and record the test shredded output G per unit time under the normal operation of the shredding machine s , according to the formula (1) to calculate the design shred output G of the shredding machine for Baisha fine second-generation tobacco leaves.

[0031]

[0032] In the formula (1), G is the designed shredded output per unit time under the normal operation of the shredder, unit kg / h; G s It is the test shred output per unit ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com