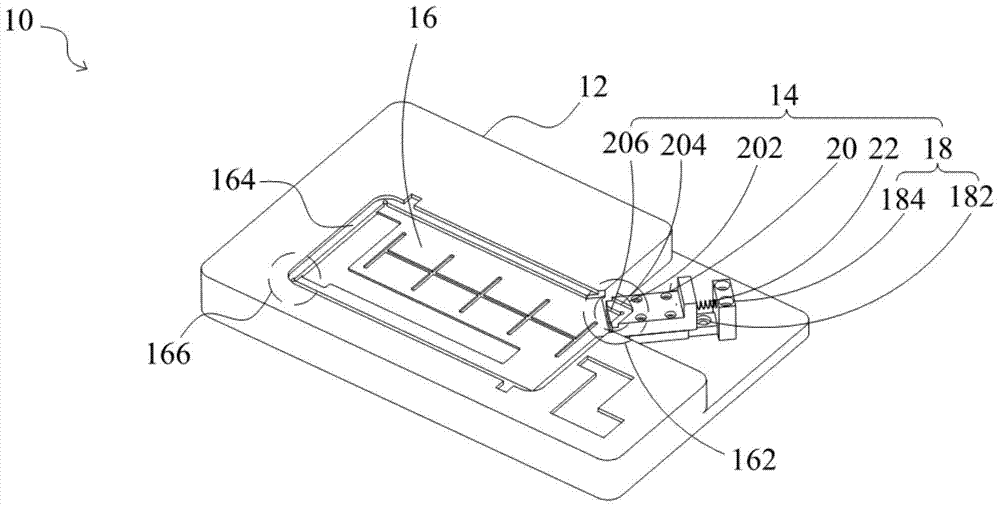

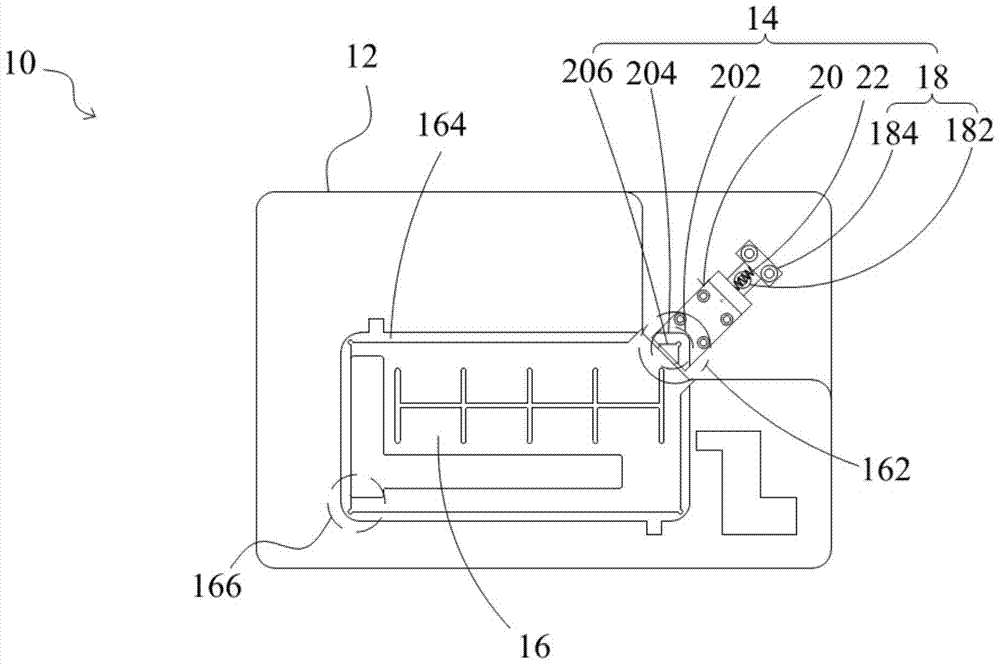

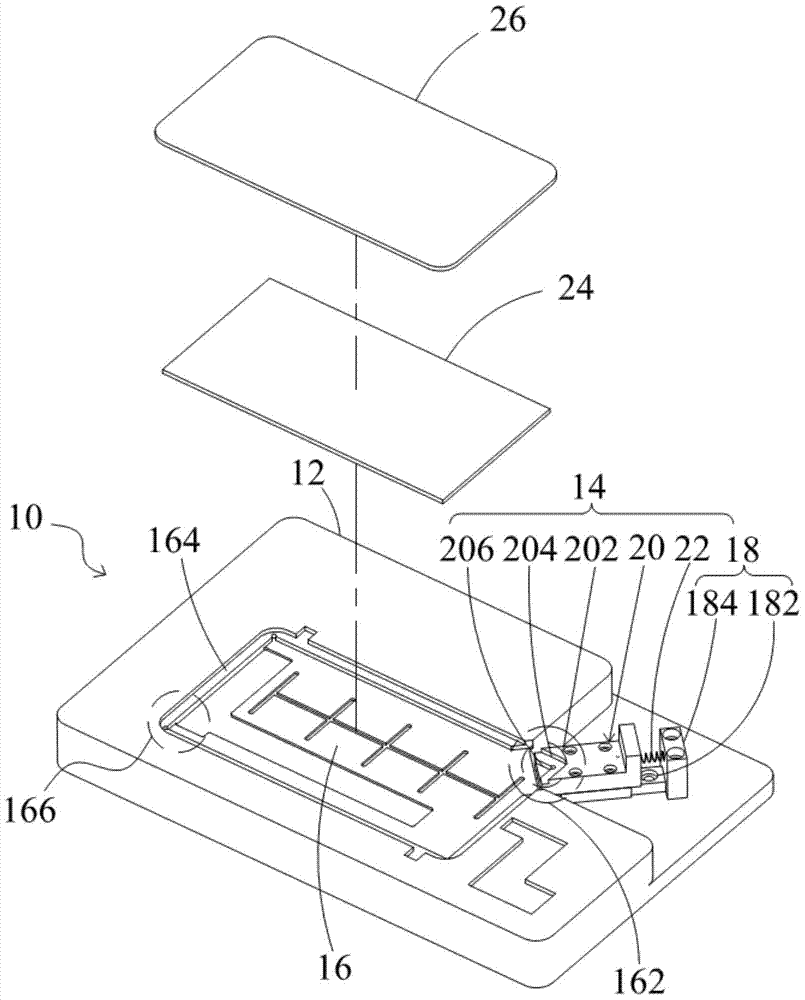

Improved Lamination Fixture for Touch LCD Module

A technology for liquid crystal modules and lamination fixtures, applied in the input/output process of data processing, optics, instruments, etc., can solve the problems of low lamination efficiency, multiple assembly tolerances, and inaccurate lamination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] With the demand for narrow bezels of electronic products in the electronic product market, more and more touch LCD modules require assembly accuracy from the viewable area (V / A) to the active area (A / A). Change from Touch Panel Edge to LCD Module Edge, and improve control accuracy from 0.3mm to 0.2mm to reduce assembly risk. At the same time, the cost reduction requirements of electronic products are applied, so that more models begin to switch from full-plane bonding (Direct Bond) to word-of-mouth bonding or frame bonding (Air Bond) to reduce material costs. Under this condition, most The hard-to-hard lamination (Hard-To-Hard, HTH) machine is no longer suitable for the production needs of such products. Because, the HTH machine photosensitive couple and component (Charge Coupled Device, CCD) capture V / A and A / A, changing to side-by-side alignment requires a lot of machine modification costs, and the HTH machine is used for Air Bond lamination Therefore, it is imperati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com