Device for increasing stations

A technology for work stations and workpieces, applied in the field of devices for adding stations, can solve the problems of difficulty in ensuring alignment accuracy, affecting product quality, wasting time, etc., to save alignment time, high product quality, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

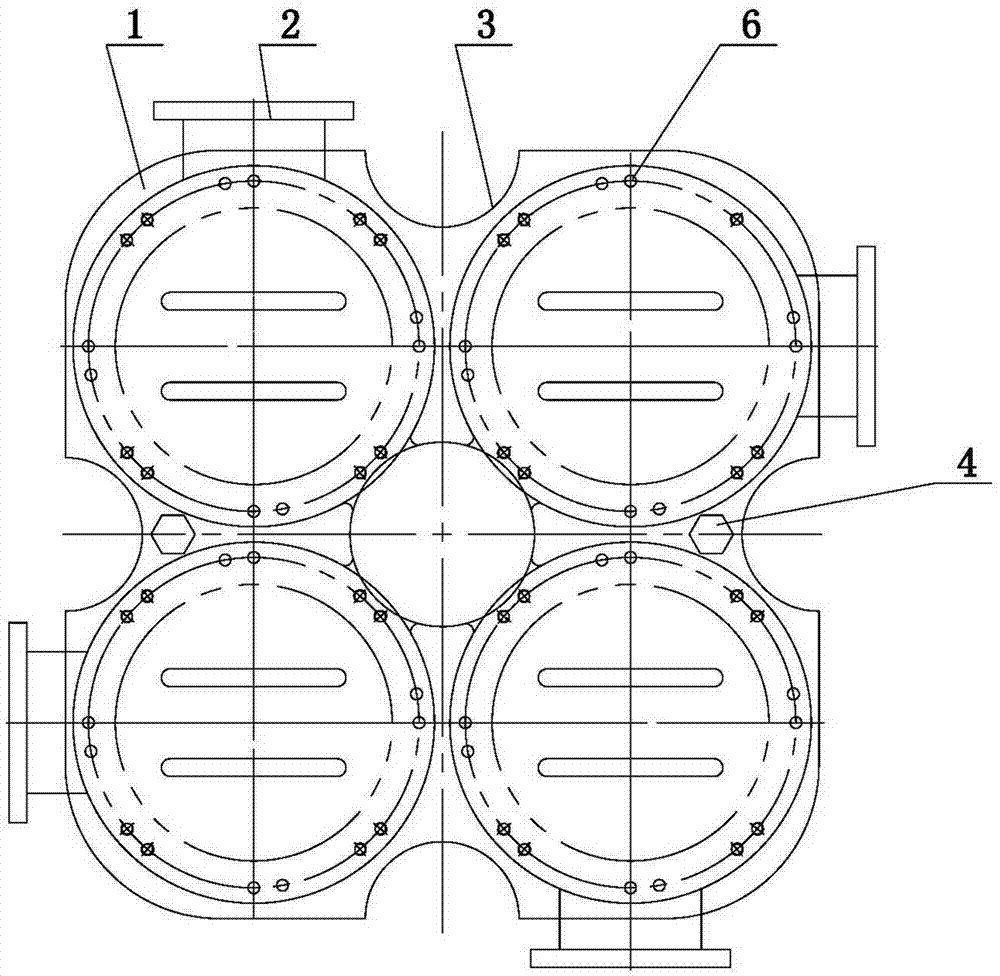

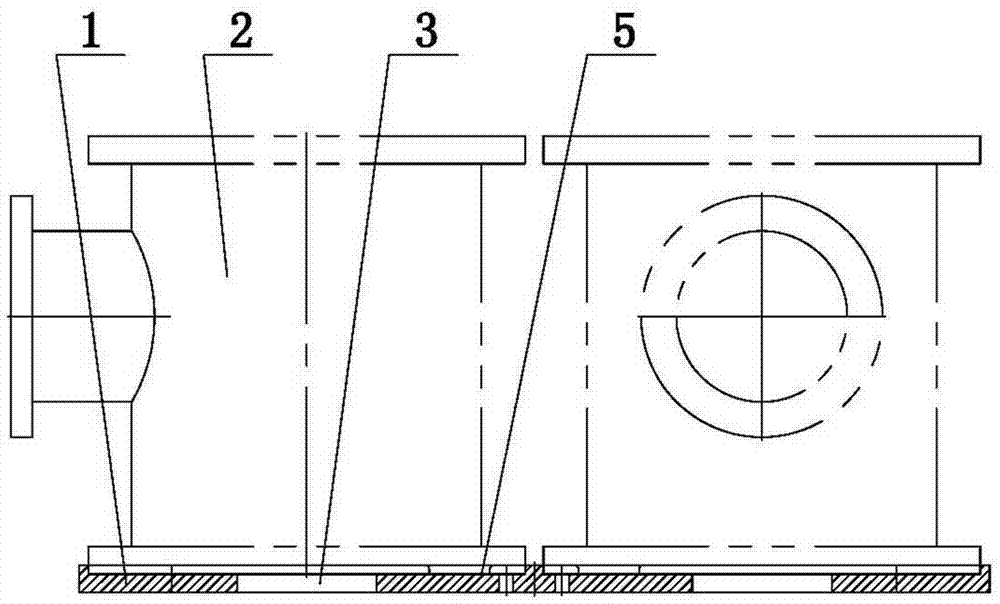

[0011] The present invention includes a square plate body 1, which is characterized in that: the surface of the plate body 1 is provided with four workpieces 2 notches 5; the center line connecting the centers of the four workpieces 2 notches 5 is a square; the center of the square and The center of the plate body 1 coincides; the said notch 5 is provided with a connecting pin hole, and the plate body 1 is provided with a mounting hole 6 outside the notch 5, and a compression bolt 4 is arranged in the mounting hole 6.

[0012] As a preferred solution of the present invention, the four corners, the center, the center of the seam, and the middle of the four sides of the plate body 1 are all provided with weight reducing parts 3 .

[0013] When the present invention is used, firstly, the center of rotation of the plate body 1 is overlapped with the center of rotation of the boring machine workbench by means of a dial indicator on the spindle of the boring machine, and then the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com