Vending mechanism of automatic meal-vending machine

A technology of an automatic vending machine and a driving mechanism, which is applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, which can solve uneven force , high power consumption, long time-consuming and other problems, to achieve the effect of shortening the transportation time, reasonable structure setting, and short moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

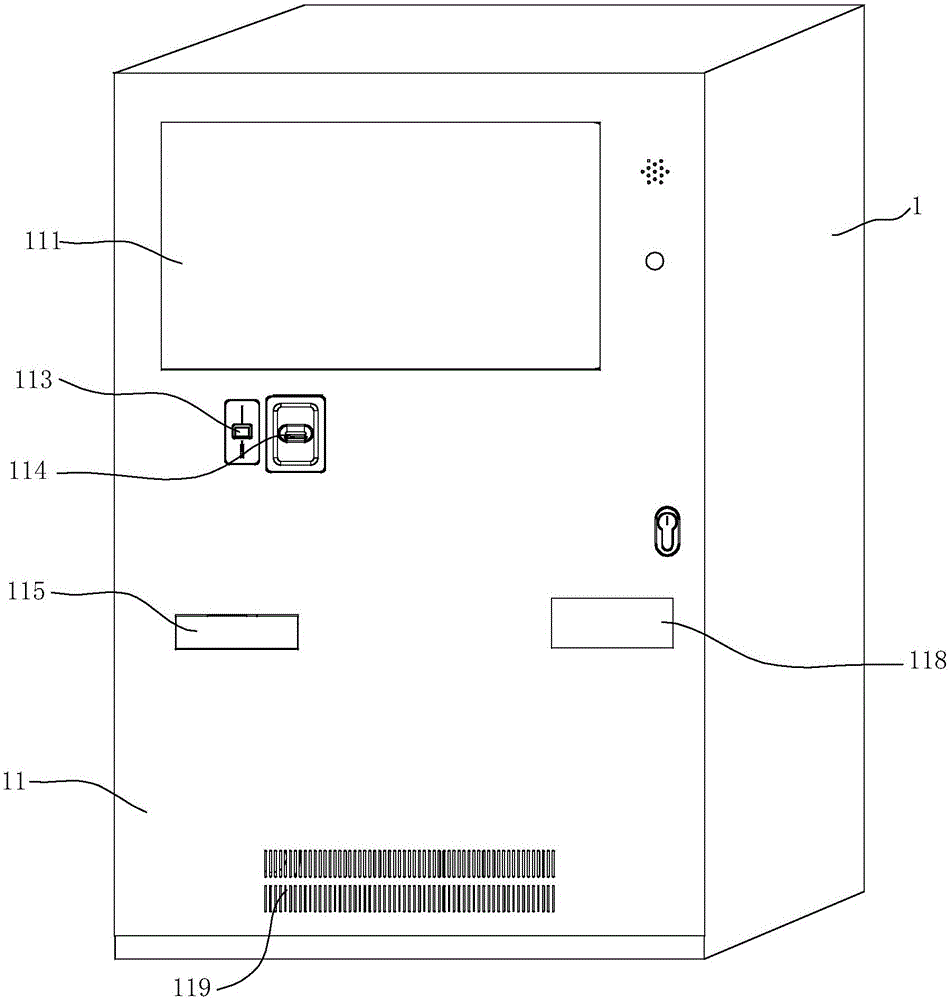

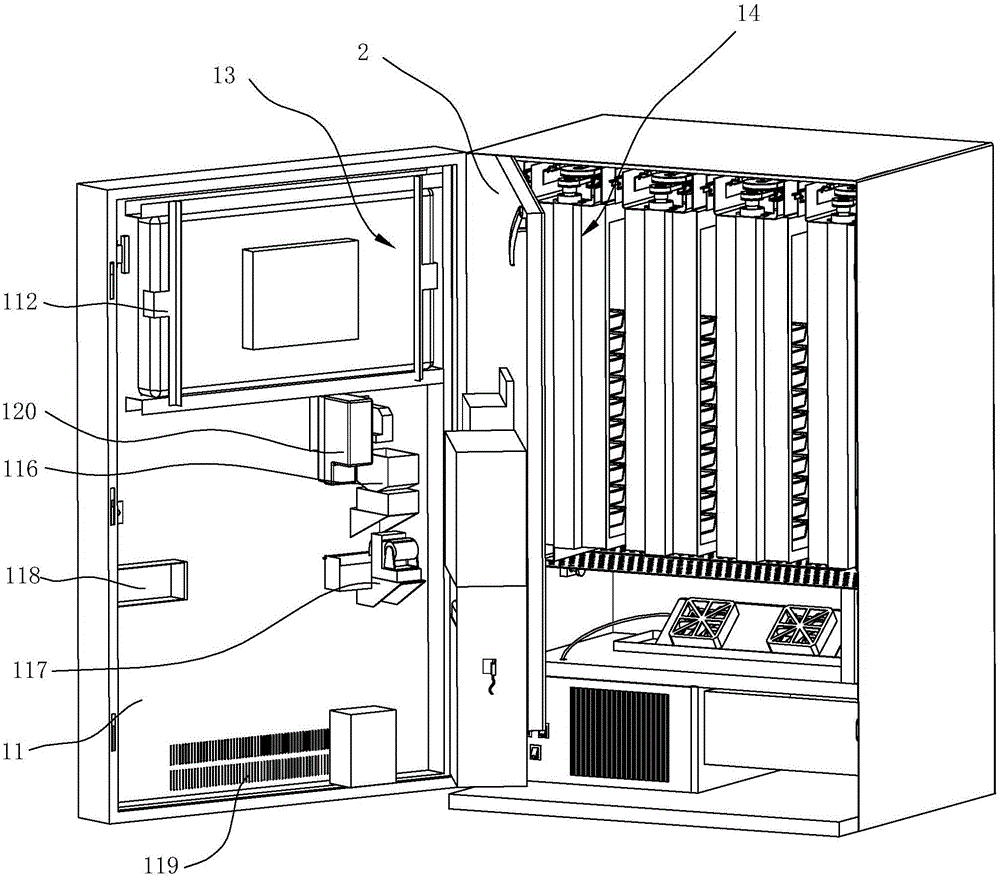

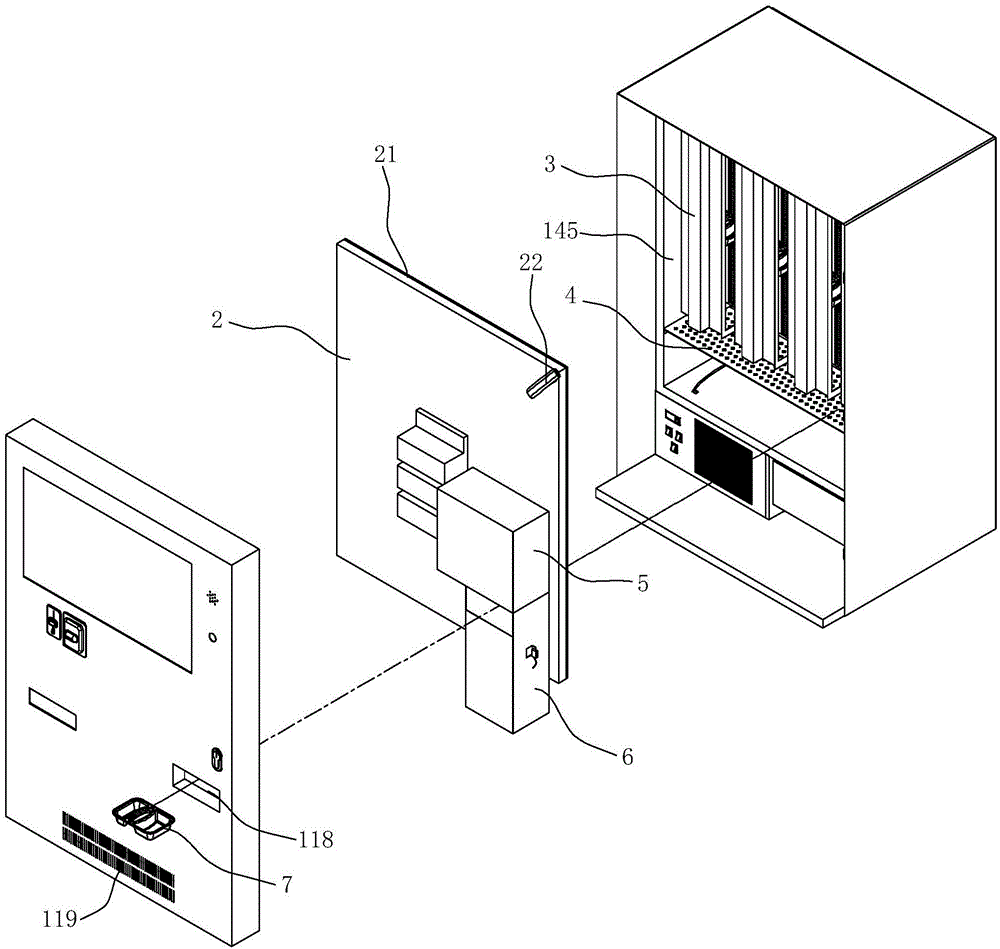

[0035] see Figure 1 to Figure 3 , an automatic food vending machine, comprising a closed casing 1 that forms an accommodating space, the casing 1 includes a top plate, a bottom plate and surrounding panels, wherein, the front side panels 11 in the surrounding panels form a cabinet door, and the front side The panel 11 is provided with a display 111 with a touch screen. The display 111 can be used to display menus and perform ordering operations. The front panel 11 is also provided with a banknote detection and banknote outlet device, including a coin slot 113, a banknote slot 114, and a small change outlet 115, which are used for payment confirmation after ordering, and a On the back of the panel 11 are a coin sorting machine 116 corresponding to the coin slot 113 , a cash register 120 corresponding to the banknote inlet 114 , and a receipt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com